Open House Showcases Five-Axis Capabilities, Digital Tools

Five-axis machining technology was the highlight of the Hwacheon open house in Lincolnshire, Illinois this August.

This August, Hwacheon Machinery held an open house at its Lincolnshire, Illinois, facility near Chicago, where it provided insights into its technology, displaying two new five-axis machine tools, as well as its in-house machine monitoring systems: M-Vision Plus and M-Vision Pro. The company also hosted representatives from FANUC to discuss programming for five-axis machining.

Five-Axis Machines for Large Parts

Many manufacturers attended the open house to learn about Hwacheon’s offerings and listen to presentations from partners. At the event, the company revealed its two newest five-axis machine tools: the D3-5AX and M1-5AX.

The event saw the introduction of the Hwacheon D3-5AX and M1-5AX, two five-axis machine tools designed to integrate easily with the company’s own pallet-changing system. The D3 is a trunnion-style five-axis machine capable of both 4+1 and full five-axis machining for large parts. It is the company’s largest five-axis machine, capable of 800 millimeters in X-axis travel and with an 800-millimeter work area. It comes standard with a 12,000-rpm spindle, with options for spindle speeds as high as 24,000 rpm.

The D3-5AX is the largest five-axis machine tool provided by Hwacheon. The work area measures 800 milimeters across, and it comes with a maximum spindle speed of 12,000 rpm.

The M1, on the other hand, is designed specifically for mold and die shops. The work area has a 300-millimeter diameter, and the spindle speeds are available at either 20,000 or 30,000 rpm. The machine’s cooling systems in both the spindle and frame ensure thermal stability over long machining cycles, which is ideal for mold and die work.

Both machine tools come standard with the company’s Harmony control.

Digital Tools, Tangible Results

The Harmony control uses a touchscreen human-machine interface on FANUC guts. Developed in-house, the control makes monitoring machine functions, simulating toolpaths and programming five-axis work accessible through simple menu options. It uses conversational CAM programming, and it has functions to optimize five-axis feed rates and simulate five-axis toolpaths. The system enables users unfamiliar with programming five-axis work to effectively adapt to five-axis machining, and users who are already used to using a FANUC control for five-axis machines can simply switch the interface to the standard FANUC option.

According to FANUC Aerospace Program Manager Rick Schultz, Hwacheon machines are adept at taking advantage of the control’s five-axis machining features. For example, the Workpiece Setting Error Compensation function enables the machine tool to identify positional errors that can occur during setup and adjust the toolpath to compensate, and the AI Contour Control uses algorithms to optimize toolpaths while taking cutting conditions into account.

“These functions are critical for five-axis machining,” Schultz said in a presentation on programming for five-axis machining, emphasizing that these functions can shorten cycle times and avoid scrapped parts. He also praised Hwacheon machines for taking advantage of these and other features. “Hwacheon is one of the customers using our most current functions. They’re one of the most prepared for five-axis machining.”

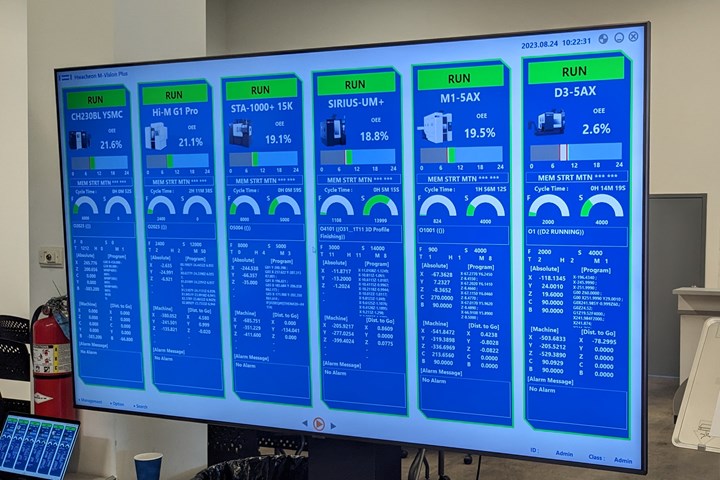

Hwacheon’s M-Vision machine monitoring provides real-time information on the uptime of machine tools. With M-Vision Pro, users also get remote access to the data, as well as information regarding the causes of any machine downtime.

In addition to controls, Hwacheon had its M-Vision machine monitoring system on display. M-Vision Plus and M-Vision Pro provide real-time data that can identify spindle utilization and alert users to problems. While both provide machine monitoring, the Pro version enables users to track data remotely, as well as pull up alarms and identify the cause of machine downtime. Visitors to the open house could scan a QR code and automatically download the machine monitoring app, providing them live data for the machine tools on display.

Related Content

Understanding Swiss-Type Machining

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the learning curve is like.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreWatchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MorePalmgren Launches Combination Bench Lathe, Mill

The 11" bench engine lathe and gear head mill is able to handle a wide range of turning, milling and drilling operations typically found on much larger machinery.

Read MoreRead Next

Obscure CNC Features That Can Help (or Hurt) You

You cannot begin to take advantage of an available feature if you do not know it exists. Conversely, you will not know how to avoid CNC features that may be detrimental to your process.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)