New Aerospace End Mill Design Results from Tool Standardization Contest

The latest version of Kennametal’s Harvi tool was developed through efforts aimed at a competition for reducing an aircraft manufacturer’s tooling choices.

Cutting tool maker Kennametal reports it was the winner of a recent competition by a “major U.S.-based aircraft manufacturer” (the company doesn’t wish to be named publicly) aimed at standardizing its solid carbide end mills. According to Kennametal’s manager of solid end milling tools Thilo Mueller, the problem the aircraft manufacturer still faces is this: An expanding number of active machined parts has led to an ever-expanding universe of cutting tools that the manufacturer and its suppliers are using. Historically, manufacturing engineering personnel have had too much freedom—more freedom than necessary—in specifying the tooling for a given part. Limiting the range of choice as much as possible to a standard menu of tools would control costs for the aircraft maker by controlling the scope of tool management. It would also help avoid unexpected delays, because those standard tool choices would become standard items that the tool suppliers would be more likely to have in stock.

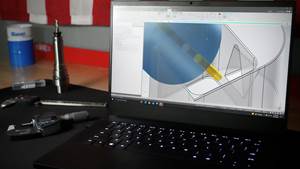

But which tools to choose? Answering that question led to the competition. Various cutting tool suppliers submitted tooling for machining trials that were conducted at the University of Sheffield’s Advanced Manufacturing Research Centre (AMRC) in the United Kingdom. To pursue better results within the test parameters, Kennametal modified an existing tool design—its “Harvi” end mill design featuring unequally spaced flutes to break up chatter, eccentric relief to extend tool life, and a tapered core for stability during heavy cutting. That modified tool is now available to the aircraft manufacturer and to others as the tool maker’s new “Harvi III Aerospace” line.

The AMRC testing focused on forged titanium 6Al4V. Three sets of cutting parameters apiece addressed both traditional-milling and high-velocity approaches for the aircraft maker. In each case, the three sets of parameters were designated as “current,” “meets” and “exceeds” expectations. In the traditional rounds, a 0.1-inch radial depth of cut was specified, with cutting speeds ranging from 150, to 200, to 250 sfm for current, meets and exceeds categories, respectively. In the high-velocity testing, depth of cut dropped to 0.02 inch while speeds increased to 400, 450 and 500 sfm, respectively.

Strict guidelines governed what kinds of tooling could be used. Initially, the solid carbide end mills in all these cases had to be 1.25 inch in diameter, with a flute length of 4 inches, corner radii of 0.09 inch and a flute count of either five or six. Further testing then evaluated different combinations of tool diameter, length and corner radius (up to the full radius of a ballnose tool), Mr. Mueller says. Tools were required to achieve axial depth of cut of 2 inches while extending from the holder exactly 4.5 inches. And in all of this (sorry, metric system), only imperial units were allowed. Within these constraints, the tooling supplier was free to put forward its best choice of tool coating, carbide substrate and cutting geometry.

Kennametal put considerable work into finding the tooling that would excel in these tests, Mr. Mueller says. The company performed its own testing at its facilities in Germany, Tennessee, and North Carolina using five different machining centers. Chip flow and formation were analyzed using high-speed cameras, and he says a refined tool-grinding processes was developed as a result of this analysis. Ultimately, nearly 300 different tools were produced for use in the project, and 15,000 cubic inches of titanium were machined.

During the final round of testing, Kennametal used a Haimer Safe-Lock shrink-fit holder and was able to run all of its tools in the exceeds category. With the traditional milling approach, less than 0.001 inch of tool wear was observed after 1 hour, with a surface finish of 23 μin Ra. Within the high velocity testing, tool wear measured less than 0.0014 inch and surface roughness was better than 27.5 μin Ra. Perhaps most significantly, the Harvi tools permitted a 20-percent higher metal removal rate than others because the design enables effective use of six flutes where other end mills were limited to five.

In the tools developed for this application, an already existing carbide grade proved effective, the company’s KCSM15 Beyond grade. The new modifications to this tooling that now exist in the Harvi III line relate to edge geometry, Mr. Mueller says.

As for the aircraft manufacturer, the evaluation continues. Future tests will evaluate inserted tools. And even the determination related to solid carbide tools will not have an immediate impact, because in the aerospace sector, parts are frequently certified and then locked against further manufacturing process change. But for new part programs developed from this point forward, the manufacturer and its suppliers will have an ever-more-focused range of cutters from which to choose.

Related Content

How to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreHow to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)