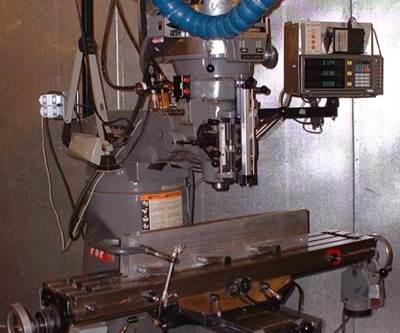

The heart of the shop’s machining capability is this VMX42i machining center from Hurco. The machining center it replaced had what proved to be too small of an envelope — Mr. Donaworth had to turn away some opportunities to machine large tools. For his second machining center, he purchased as much size and capability as he could. Read the shop’s story below.

Do you like setup? That is, at the machine tool, in preparing for a job, do you like the work of thinking through how the part should be held, how the part should be machined and how to efficiently put the setup in place?

Dan Donaworth does. He likes setup, and he says this seemingly small preference is important to the success he’s had so far. He is the president, founder and sole employee of Dan’s Custom Machining in Williamsburg, Ohio, the four-year-old shop that became his only employment when he quit his day job late last year at age 27. (He is now 28.) And when Mr. Donaworth mentioned this characteristic about himself — that he enjoys setup — that was a moment in which I could immediately relate. I believe I understand, because when people ask me if they might be suited to my work, writing, I ask them: Do you like paragraphs?

To write is to make paragraphs. You ought to appreciate paragraphs, or you won’t enjoy what you’re working with moment by moment and day by day. In the same way, to be the owner of a startup job shop is to do setups, lots of setups, and success comes from doing them quickly and well. Trying to build a new business is so challenging. It is valuable, even essential, that the one who is building it at least enjoy the daily realities of the work.

Today, what it takes to launch and succeed with a startup machining business is arguably becoming a more important and relevant question. From a macro view, we need more machining businesses — we need more shops. Many decades-old job shops in the United States will close or be acquired in the coming few years, as their baby-boomer founders reach retirement without successors. New shops founded by millennial entrepreneurs could be a partial answer and could take up opportunities these shops leave behind. Yet from a more micro-level view, realizing this solution is challenging. New shops face high barriers to thriving. OEMs’ increased reliance on established and certified supplier networks keeps new shops from winning the kind of high-value work that can help them find stability and start to grow.

New shops face high barriers to thriving. OEMs’ increased reliance on established and certified supplier networks keeps new shops from winning the kind of high-value work that can help them find stability and start to grow.

Mr. Donaworth seems to be pulling it off. Business is growing year on year, and the variety of current customers and the work they are likely to bring suggests 2020 will be the shop’s most lucrative year yet. But there is no end to worries and challenges, and no sense that this shop has necessarily found a reliable, winning formula. Indeed, likely there is no certain formula for success as a startup job shop, just essential ingredients: good fortune, commitment and relationships. Mr. Donaworth leveraged all three. His experiences are worth sharing as an example of a journey many other young machinists aspire to take, and a dream many of them wish to see realized.

I visited him and spent time talking with him in his shop. Here is what living the dream looks like:

1. Part-Time Is the Hard Road That Comes First

On a resume, Mr. Donaworth would appear to have been a job-hopper. In 10 years, from ages 17 through 27, he worked in machining-related roles with seven different employers. Though he never stayed in one place long, he departed on good terms with all of these companies, he says. As evidence, some of the former employers are now his customers. In each case, it was clear to the employer he wasn’t leaving for a better wage, but instead he was leaving because the next job was more challenging and offered him the chance to experience still more about machining or machine tool technology. Through all this time, it was apparent to people around him that he loved machining, and they all knew it was the work of his life.

Here is how the machine shop began. Mr. Donaworth bought this lathe with the idea of manufacturing a friend’s invention. That product never materialized, but a new machining business did.

Even so, the dream to start his own shop was not one he was confident he would pursue. “The money scared me,” he says. The steady wage of an employee was more comfortable than the uncertain income of a small shop. But the dream was there; when he bought a house at age 21, he chose a property with a large shed that could house a small shop. Later, when a friend had an idea for a new product (a fishing reel design), he bought a manual lathe so he could manufacture it, and he had the building wired for three-phase electrical power. That new product never came about, but by that point Mr. Donaworth was far along with equipping a shop — far enough to continue. He bought a manual mill and won a customer, Superalloy Manufacturing Solutions (previous GKN, until Superalloy bought a local facility from this company), one of his former employers.

“The money scared me,” he says. The steady wage of an employee was more comfortable than the uncertain income of a small shop. But the dream was there….

What began then was a three-year period of working in the shop part-time in addition to working full-time as an employee elsewhere. The employer during this time was GE Aviation, where Mr. Donaworth worked as a machinist. And the “part-time” in his shop looked very much like full-time in its own right. For two years, he worked third shift at GE, then 7 a.m. to 4 p.m. in his own shop. For one year after that, he worked a Friday-Sunday shift at GE, with Monday-Thursday devoted to Dan’s Custom Machining.

This period of time was often dismal, he says. His wife Chelsea Donaworth would frequently shake him out of bed, reminding him, “This is your dream!” Above, I mentioned good fortune as one of the ingredients for success. A big part of Mr. Donaworth’s good fortune is found here: in having found and married a spouse who reminds him what his dreams are.

2. Cash Flow Is the Life of the Business

The fact that Mr. Donaworth was scared about money simply reveals that he understood the challenge correctly. Income for a small shop is unpredictable while the expenses are numerous. Indeed, being a young startup shop is in some ways more expensive than operating as a shop that is more established.

Another important stroke of good fortune Mr. Donaworth enjoyed was this: Through ages 23-24, he had a lucrative job — annual income above $100,000 — involving fabricating parts in the field for machine service. The good fortune was joined with good sense; he saved much of his earnings from this work, and the savings became the cash foundation for the business he would ultimately launch.

RELATED: See Dan’s Custom Machining in action. “The Cool Parts Show” visited Dan’s for test machining with a 3D printed end mill. Watch the episode here.

Math told him when the moment had come when he could go out solely on his own. The production ramp-up of the F110 fighter aircraft promised to bring him a steady flow of work machining tooling for his customer Superalloy, and this flow by itself could be just enough to sustain the shop. A small amount of prototyping work from a major company in the area, Procter & Gamble, assured a little extra revenue beyond this minimum. With just this much, Mr. Donaworth could support himself and begin to grow the business.

But he wouldn’t be thriving. At present, he pays himself a salary of $24,000. His wife’s income helps support the household. Income from the machine shop largely goes back into the machine shop.

“People interested in the cost of a shop always ask me what machines I’ve bought,” he says. “The machine is just a fraction of the cost. The costs go way beyond this. There’s also workholding, gages, cutting tools. You’ll spend $6,000 just on dowel pins.”

“The machine is just a fraction of the cost. The costs go way beyond this. There’s also workholding, gages, cutting tools. You’ll spend $6,000 just on dowel pins.”

Cutting tools in particular are notably costly. Dan’s Custom Machining does aerospace-quality work, which requires high-end tools along with shrink-fit toolholding. Yet the shop is also a job shop, and a hungry one at that. It has to be ready for any job that comes, and it has to be ready to jump at short-lead-time opportunities. The only way to do this is to have a large and costly inventory of tooling on hand and ready to use, he says. This highlights how success can bring savings, because a well-established shop with steady production contracts could better predict its tooling needs and thereby spend less on tooling.

“Doing one-offs means you do not have the option to go cheap on tools,” Mr. Donaworth says.

3. The Machine Tools Are Both Too Much and Never Enough

He says he wanted to own his own shop so he could make his own decisions about the machining technology he uses — not muddle through with the resources chosen for him by an employer. He enjoys that privilege now, but getting to exercise this choice is demanding. His newest and most sophisticated machine tool, a VMX42i machining center from Hurco, “cost more than my house,” he says.

One of the pleasures of being a shop owner in the case of this shop: The commute is a breeze. Mr. Donaworth’s home and business are on the same property.

Yet he has seen the importance of making the stretch — buying all the capacity he can afford. His first programmable mill was affordable, but he has to tend this machine. He can never get far from it while a job is running. His first full CNC machining center fit the financing he could get at the time, but its travels ultimately proved too small. There was potential tooling work from his primary customer he couldn’t accept. The Hurco machine’s travels are much larger. He notes this machine also has the rigidity to work faster by realizing heavier material removal rates, and its conversational control will be an asset to him when the day inevitably comes that he seeks to hire and develop an employee.

The challenge related to equipment financing is one that vexes him. His parents urged him to attend college, and he did so to honor them, but he knew he wanted to be a machinist and he continued in this work during his schooling. Later he discovered how the availability of loans seems to exert this very same bias and pressure. “I can easily get a college loan for any questionable subject I might want to study,” he says. Why is it so difficult to get financing along a different path, building an industrial business?

4. Business Comes from Relationships

Again, Mr. Donaworth was once employee of his current customer, Superalloy Manufacturing Solutions. A friend still working for Superalloy at that time connected him with the purchasing department there. “Otherwise I wouldn’t have gotten the work,” he says. Indeed, his decade of job hopping was unintentionally a decade of establishing relationships with future clients. At the moment I paid him a visit, every one of his active clients except for Procter & Gamble was a former employer.

Relationships matter, he says. Relationships are practically essential. “The days of knocking on doors and getting business are over,” or at least this has been his experience. Ditto the promise of digital marketing — what effort he has been able to give to email and social media outreach has brought him little result. (Discounting the fact that you are reading this article now because social media is how I first became aware of him.)

Relationships matter, he says. Relationships are practically essential. “The days of knocking on doors and getting business are over.”

He attends to relationships because he knows how much the people he interacts with matter. “Purchasing people tend to like me. I get quotes back fast,” he says. Machine tool service people are also valuable; they visit a lot of plants. “I find connections through my connections,” he says. This is the only viable avenue he has found to finding new business.

Significantly, his machine tool supplier could say much the same. Mr. Donaworth was not committed to buying a Hurco machine. However, he appreciates the machine tool distributor representing this builder, Reynolds Machinery. He feels he gets the attention of this distributor despite the small size of his shop. The machine tool supplier would have to argue that relationship is the reason why it won business as well.

5. The Challenges Are Personal, So the Rewards Have to Be, Too

He likes setup. He likes the challenge of it — figuring out how to successfully hold and machine a part with difficult features. “There is no better feeling than overcoming an obstacle,” he says.

By contrast, what he hates is the stress. This never ends. Week after week, there is always the challenge of obtaining more work and the question of whether more work will come.

The shop once suffered through a two-month spell in which three small jobs were the only work. Cash in reserve let the shop endure. “I have enough that if I hit a three-month shutdown, I would be OK.” He hopes this never happens, but that much buffer is there. It answers the stress just enough to make the way forward manageable.

If the stress is greater, the heartache and the slog are at least reduced. Before he went out solely on his own, when he was working in his own shop while also working for an employer, there was nothing to do except to work all the time. It was understood among Mr. Donaworth’s family members and friends: He missed special occasions. He missed holidays. He had to keep working. Since going out on his own, that part is over. He takes holidays off and he makes it to special occasions now.

The income might not come. This is true for any of us, of course, but the startup shop owner works every day staring directly at that reality. On many days, something else has to come instead — some other reward. Mr. Donaworth finds it in the challenges of machining parts and the challenges of running a machining business. That is, he finds reward in what the challenges have given him. Since launching his shop, and in particular since making it his full-time employment, he says, “I have grown in my career as a machinist 100 times more than I could have imagined.”

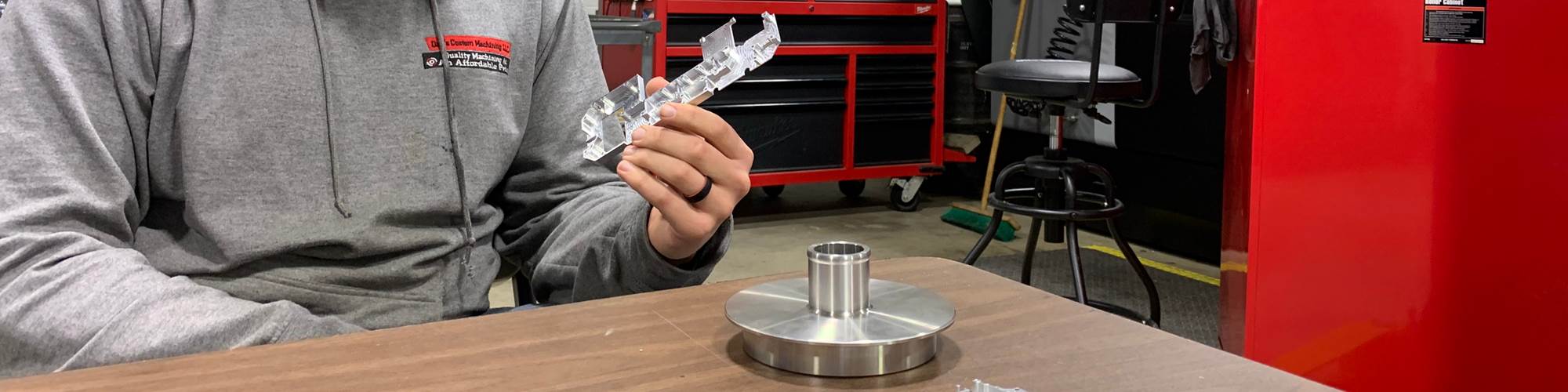

Here is another reward: challenging, short-run parts. Many would say this is one of the difficulties of being a job shop owner, and it is that. But Mr. Donaworth loves the mental challenge of machining — finding the right setup and process for a machining a difficult part. This part is just one example; its challenges included holding it without distortion while machining thin walls and a thin floor. A workholding adhesive proved to be part of the solution in this case.

Related Content

Volumetric Accuracy Is Key to Machining James Webb Telescope

To meet the extreme tolerance of the telescope’s beryllium mirrors, the manufacturer had to rely on stable horizontal machining centers with a high degree of consistency volumetric accuracy.

Read MoreHow to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreThreading On A Lathe

The right choices in tooling and technique can optimize the thread turning process.

Read MoreWatchmaking: A Machinist’s View

Old-world craftsmanship combines with precision machining on a vertical machining center and Swiss-type lathe to produce some of the only U.S.-made mechanical wristwatch movements.

Read MoreRead Next

Hope Is an Asset: Here Are Machine Shops Following Clear Visions for the Future

A simple strategy offering a clear aim to hope for is particularly valuable during a disruptive time. Recently posted articles offer examples of shops following clear ideas for the way ahead.

Read MoreOpen Your Own Machine Shop? Here is Advice On Starting Small

Read what shop owners had to say to someone who wondered whether he should open a very small shop of his own.

Read MoreVideo: Starting Your Own Machine Shop — the Rewards and Challenges

The owner of Dan’s Custom Machining on the decision to go full-time with his machining business, advice for future shop owners, and whether buying machine tools is fun.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)