A Deeply Holistic Approach

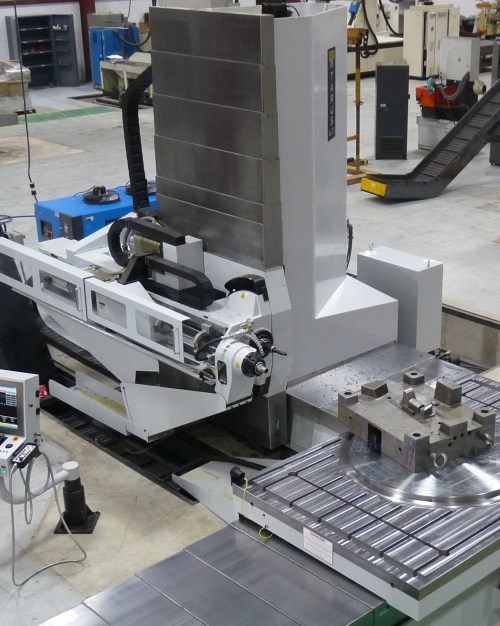

In its effort to streamline every step of the mold building process, this company has upgraded its deep-hole drilling capability with a new six-axis machine. A rotary table with magnetic workholding enhances this machine’s flexibility.

Many U.S. mold shops have made impressive progress in their ability to build molds faster and better. They’ve had to, because it’s the only way to compete with low-cost mold builders overseas. Roush Manufacturing’s mold building operation in Farmington, Michigan, is certainly no exception.

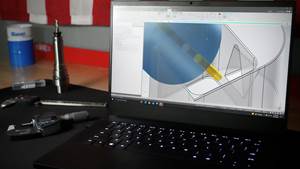

A large and diverse manufacturing company, Roush has been building molds since 1987. In recent years, the company has aggressively upgraded various aspects of the mold building process. For example, it has moved from 2D to 3D CAD so that mold designs can be completed in roughly half the time that it formerly took. Likewise, it has added several high-precision, five-axis machining centers for high speed milling of complex, contoured mold surfaces. These machines allow even large mold components to be machined with no excess stock, a technique called “cutting to zero” that has reduced hand work and spotting time by as much as 90 percent in addition to speeding delivery times.

Now the company has taken a step to streamline its deep-hole drilling capability. A new six-axis, deep-hole drilling machine from Tarus Products allows Roush Manufacturing to drill deep holes at compound angles with relative ease and much greater speed. Several features of this machine stand out. One is the tilting drill slide unit, which incorporates both a primary spindle for gundrilling and an auxiliary spindle for operations including drilling, tapping, boring, chamfering, spotfacing, slot cutting and face milling. Another important feature is a 360-degree rotary table with integral electropermanent magnetic chucking. Together, these features greatly reduce setup time in addition to eliminating multiple setups to complete a tool.

According to Mark Slack, Roush Manufacturing’s director of operations, hole-making jobs that formerly took as many as 60 hours of setup and machining time on a four-axis drilling machine can be completed in as few as 15 hours on the new machine. “We can drill water lines that follow mold contours more closely, giving us the opportunity to positively affect tool cycle times,” he explains.

Roush: More Than Racing

The Roush name is probably best known for its involvement and achievements in the performance racing industry, which is where the company got its start in 1976. Branching into related engineering and manufacturing industries, Roush now has numerous divisions that serve not only various aspects of the automotive sector, but also aerospace, medical, defense, entertainment, renewable energy and alternative fuels industries, to name a few. It provides engineering, testing, prototyping, manufacturing and technical communications to customers in those and other industries. Roush’s manufacturing capabilities include reverse engineering, rapid prototyping, tool design/build, NC machining, and low-volume injection molding and blow molding. Overall, Roush employs more than 2,500 and has numerous facilities, most of which are scattered across the greater Detroit area.

The building in which most of Roush’s tooling operations are now housed is one of its newest facilities. It’s located in Farmington, only a few miles from Roush’s headquarter campus in Livonia. The company acquired the 110,000-square-foot building in 2008 and began relocating equipment from three other buildings at the beginning of 2009. In addition to its existing machines, the company also installed several new CNC machines, including the deep-hole drilling machine, in the new facility.

While walking through Roush Manufacturing, it is clearly evident that the company has invested heavily in high-end machine tools, including five-axis machining centers from Makino, Fidia, Parpas and other European and Japanese builders. It is also clear from the varying sizes of these machines that Roush specializes in small, medium and large molds with plastic molding machines that range from 250 to 3,300 tons.

The deep-hole drilling machine, installed in the first quarter of 2009, stands out not only for its advanced features, but also for being built in Michigan. Tarus Products Inc. is located in Sterling Heights and has been building deep-hole drilling equipment, milling machines, coordinate measuring machines and other special-purpose machines since 1969.

Heavy-Duty Drilling

The Tarus machine certainly fits in with the other hefty machine tools in Roush Manufacturing’s facility. This machine is designed for heavy-duty, deep-hole drilling in large workpieces weighing as much as 60,000 pounds. The machine’s configuration is somewhat similar to a traveling-column horizontal milling machine. The column moves 46 inches in the Z axis. The drilling and milling assembly travels 60 inches in the Y axis on the column and tilts 15 degrees up and 15 degrees down. The main table, which is 96 inches wide and 62 inches deep, has 130 inches of travel in the X axis. The rotary table integrated into the center of the main table measures 52.76 inches in diameter.

According to Alex Khatri, general manager of Tarus, the design and operation of the tilting drill slide has advantages over designs found on other deep-hole drilling machines in this class. For one, the pivot point of the tilt is at the “front” of the column rather than in the center of the slide unit. “This affords a much larger envelope of usable vertical travel on this machine compared to conventional center point designs,” Mr. Khatri says. Additionally, the large bearing surfaces on which the slide unit articulates provide the rigidity required to resist high drilling forces.

Having the primary drilling spindle and the auxiliary spindle mounted side-by-side (one is extended while the other is retracted) on the tilting slide unit also offers advantages, he says. For example, the auxiliary spindle can be used to carry out a spotfacing operation that machines a circular pocket whose bottom will be at the exact compound angle at which drilling will be performed. This allows the tip of the drill to enter the workpiece normal to the surface, while the sides of the pocket provide an effective seal that contains the flow of high-pressure oil customarily used in gundrilling operations.

The primary drilling spindle can use either conventional gundrilling tools or the newer single-tube-system (STS) drills. Conventional gundrills feed high-pressure oil through a hole down the inside of the drill. A large, V-shaped flute on the side of the drill allows the oil to carry chips up and out of the hole being drilled. STS drills, in contrast, have a hollow drill tip that screws onto the shaft of the tool, which is also hollow. Oil is forced down the outside of the shaft and into exit holes at the tip of the tool. Thus, chips are flushed up through the interior of the drill shaft. Oil is chilled and filtered by a large-capacity, three-stage filtering system and fed to the Tarus machine from a below-ground, 700-gallon oil reserve.

According to Mr. Khatri, STS tooling works best for holes 5/8 inch or larger in diameter. STS tooling provides higher drilling speeds than conventional tooling, whereas the latter produces straighter and more accurately sized holes. With STS tooling, the machine at Roush Manufacturing can produce a 1-inch-diameter hole in P20 tool steel at 9 to 10 ipm. Holes as deep as 84 inches can be drilled in one stroke with either type of tooling. Switching from conventional to STS tooling takes approximately 15 minutes, he says.

The spindles are powered by two identical 30-hp motors, but the main drilling spindle is geared for a maximum of 3,400 rpm whereas the auxiliary spindle is geared for a maximum of 2,000 rpm. The lower gearing gives the auxiliary spindle more torque to perform the various machining processes mentioned above in tool steel.

Another “Attractive” Feature

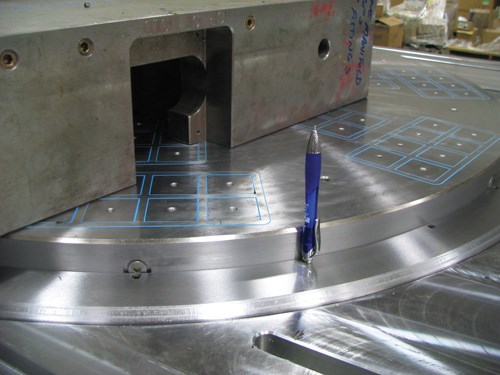

Mr. Khatri considers the magnetic rotary table integrated into the main table another major benefit because it simplifies setup and makes the machine more flexible. No clamps or fixtures are necessary for steel workpieces. He adds that the main advantage of integrating the rotary table into the main table is the low profile of the magnetic workholding surface. It is only 1.75 inches above the surface of the main table (see the photo below). Mounting a separate magnetic chuck on the table would reduce the available work envelope significantly because of the added height.

The magnetic chuck was provided by WEN Technology (Raleigh, North Carolina). This company installs the magnetic chucking unit into the rotary table and returns it to Tarus for assembly and finish grinding. Because magnetic chucking is built into the rotary table, the power cables that actuate the chuck are inside the body of the rotary table. This protects them from oil and chips that might interfere with the power system of the chuck. Control functions for the magnetic chuck are integrated in the machine’s CNC.

Setup reduction is highly attractive to Mr. Slack. “We just set a steel mold component on the table and switch on the chuck,” he says. “The system automatically squares the work to the table and we are ready to drill.” Tarus refers to this automatic system as “bump-and-go.” Essentially, this system involves touching the tool tip to the face of the workpiece in two places and “doing the trig” in the CNC system. The software calculates the angle offset to compensate for any out-of-square placement of the workpiece. No other routines are required to pick up the location and orientation of the workpiece.

More Than Molds

According to Mr. Slack, the deep-hole drilling machine will do more than bring greater efficiency and capability to mold building. “It’s a manufacturing resource that has applications in other industries that Roush serves,” he says. “We expect to use it for aerospace, oilfield and wind turbine work, for example.” Drilling holes in large engine crankshafts is another application the company is considering for this machine.

Nevertheless, the greatest significance of added deep-hole drilling capability is the statement it makes about Roush Manufacturing’s level of competence in mold building. The ability to drill waterlines, ejector pin holes and lifter holes in molds is a major step in the company’s campaign to update every aspect of mold building. Of course, this “holistic approach” to renewal does not have an end point. It implies a constant vigilance to spot opportunities for further improvement, wherever they lie.

Related Content

How Lowering Torque Improves Tapping Tool Life

Escaping the tap breakage trap requires a long look at torque and the many factors that influence it.

Read MoreForm Tapping Improves Tool Life, Costs

Moving from cut tapping to form tapping for a notable application cut tooling costs at Siemens Energy and increased tool life a hundredfold.

Read MoreHow to Tackle Tough Angled Pocket Milling With Two Tools

Milling a deep pocket with a tight corner radius comes with unique challenges, but using both a flat bottom drill and a necked-down finishing tool can help.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)