Published

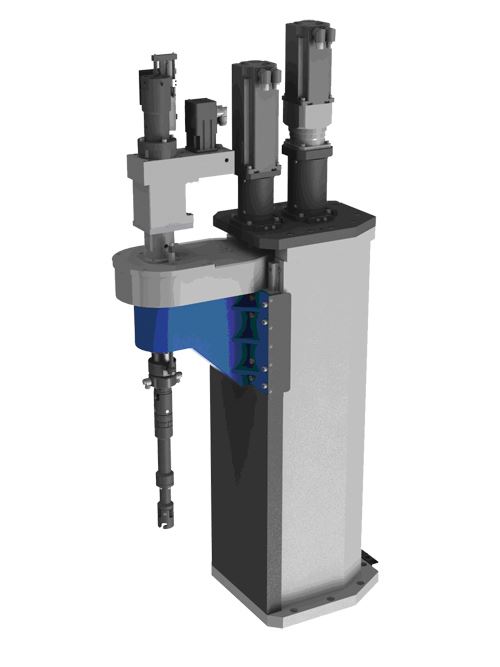

A Three-in-One Honing Station

Combining roughing, finishing and gaging in one station is a distinctive capability of the ECO 80 dual-expansion honing system from Nagel Precision (Ann Arbor, Michigan). The system is designed for low- and medium-volume applications that require submicron bore sizes and mirror finishes.

Combining roughing, finishing and gaging in one station is a distinctive capability of the ECO 80 dual-expansion honing system from Nagel Precision (Ann Arbor, Michigan). The system is designed for low- and medium-volume applications that require submicron bore sizes and mirror finishes. It can finish bore sizes ranging from 10 to 80 mm.

According to the company, honing systems typically require separate stations for roughing and finishing because each operation requires different grit sizes on the respective diamond honing tools. The dual-expansion system on the ECO 80 allows tools with different grit sizes to be mounted on the same spindle. Separate systems control the mechanisms within the spindle that expand the roughing or finishing tools. The expansion for roughing is driven by servo motors, whereas the expansion for finishing is hydraulically actuated. The finish honing operation commences automatically after the roughing operation reaches the pre-determined bore size.

An automatic tool wear compensation system links in-process gaging with the honing spindle. By gaging every part, bore size can be monitored continuously and submicron adjustments can be made to honing parameters to compensate for tool wear. The company says this approach is an improvement over manual compensation systems typically found on other equipment for low- and medium-volume applications, in which over- and under-compensation is a problem.

According to the developer, the tool wear compensation system is designed to further reduce non-cutting time while improving bore quality. Once inserted in the bore, the tool expands at a “rapid” feet rate of 220 microns per second at 45 percent of available torque until it reaches a pre-determined bore size close to the desired limit. It then switches to an expansion rate of 200 microns per second at 15 percent of available torque to avoid tool damage. Toward the end of the program cycle, the tool expands at only 2 microns per second at about 10 percent of available torque. The system constantly monitors both the tool expansion rate and percentage of available torque. The operator can reduce the tool expansion rate for tighter tolerances or increase the torque for faster cycle times. This approach is said to yield a more consistent bore in terms of finish, size and cylindricity.

According to the company, the gaging system automatically checks the bore for form errors such as taper, hourglass, barrel shape, ovality and others. Automatic adjustments correct the specific kind of error detected.

Company engineers customize the tool matrix to the user’s material and bore geometry. The combination of correct tool selection and equipment settings is said to yield surface finishes below 0.05 micron Ra from a starting roughness of 1.07 micron Ra. gear-driven index table enables part loading and unloading during the finishing operation. Loading and unloading can be automated or accomplished manually.

.png;maxWidth=300;quality=90)