An Electrochemical Option for Blisks, Blades

This machining platform offers the non-contact electrochemical/precision electrochemical processes for five-axis milling of turbine engine blades and blisks.

There are two primary compressor rotor designs for modern turbine engines. The first features separate disk and blade components. For this design, individual, contoured blades install around a disk’s periphery by fitting into precisely machined root-form slots. The second is a “blisk” design, in which a disk and its peripheral blade profiles are machined from a single billet of material. Because of the extreme heat generated in the high-pressure compressor area of a turbine engine, these components are commonly manufactured from titanium or high-nickel-content alloys, such as Inconel.

Five-axis machine tools are commonly used to rough and finish-machine blisks and blades. However, Jonathan Chomicz, a technology specialist for German machine tool builder Emag, notes that an alternate, non-contact machining process can be more productive for these applications. This process combines an electrochemical machining (ECM) roughing operation and a precision electrochemical machining (PECM) finishing operation on the Emag PO 900 BF machine platform. Chomicz says ECM/PECM offers 10- to 30-percent faster cycle times than conventional five-axis machining of blades and blisks, does not create burrs, and achieves fine surface finishes to 0.05 Ra.

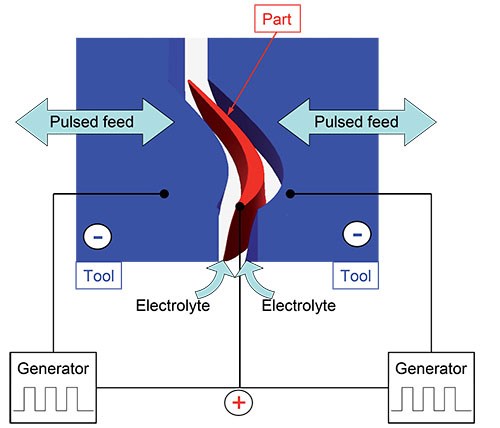

Both ECM and PECM remove metal through electrolysis, whereby the conductive workpiece is the positive anode and the tool is the negative cathode. The DC charge that crosses the electrolyte-flushed gap between the two causes the molecular erosion of the workpiece. Thermally neutral, the ECM/PECM processes can effectively machine the otherwise challenging-to-mill materials that comprise blades and blisks with no recast layer and minimal tool wear. In fact, it’s not unusual for tools commonly made from brass or 304 stainless steel to produce 4,000 to 5,000 parts during a production run, Chomicz says.

That said, PECM differs from ECM in a few ways. PECM features a synchronized oscillating tool motion to ensure that the electrolyte is properly replaced and renewed. The gap between the tool and the workpiece through which the electrolyte is flushed is narrower, too. A narrower gap offers a more effective arrangement of electrical field lines and results in more accurately machined profiles. PECM also uses a pulsed voltage power source to facilitate current flow across the gap during the tool movement. The “on” pulse creates higher current densities to deliver improved machining accuracy. The “off” pulse assists in electrolyte exchange and heat dissipation, which is why better surface finishes are possible.

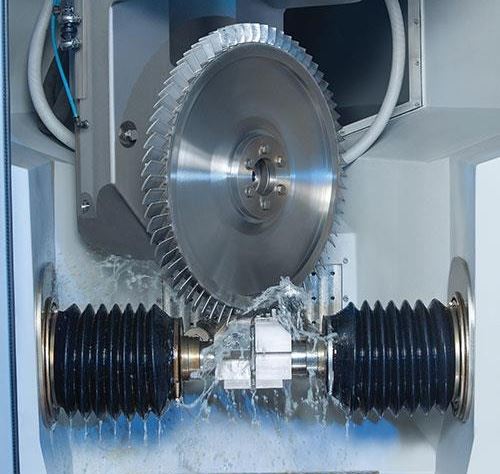

During finishing of blade profiles, the PECM process uses two tools to machine both sides of the profile simultaneously (see the drawing). Plus, scaling of tools and power supply enables large blades and blisks to be machined at the same feed rates and cycle times as smaller ones. Accurate monitoring and adjustment of voltage, current and electrolyte flow offer optimal process stability, Chomicz says, while an electrolyte management system ensures that electrolyte properties such as pH, conductance, temperature and purity remain constant.

The Emag PO 900 BF machine platform offers power ranging to 20,000A DC and a pulse rate of 30,000A. It can accommodate blisks as large as 900 mm in diameter and single blades as tall as 250 mm.

Related Content

Beyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreThe Strategic Value of Machine Tool Flexibility

This aerospace and defense supplier has a strategy to take advantage of the flexibility in its newest and largest five-axis gantry-type machining center.

Read More10 Tips for Titanium

Simple process considerations can increase your productivity in milling titanium alloys.

Read MoreHow to Turn Machine Shop Downtime Into Process Expertise

To take advantage of a lull in business, JR Machine devised a week-long cutting tool event that elevated the shop’s capabilities with aerospace alloys.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)