Published

An Unexpected Payoff

An Ethernet communications system purchased to improve productivity on one part family ended up having a broader impact on this printing press manufacturer’s business.

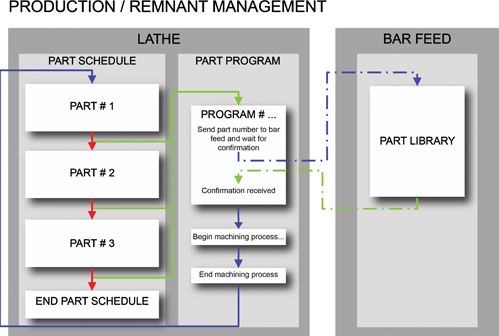

Have you ever made a decision that not only turned out well at the time, but also delivered more substantial, unanticipated benefits later? Steve Sander has first-hand experience. As machining manager at Nilpeter, a printing press manufacturer near Cincinnati, Ohio, Mr. Sander played a key role in the company’s decision to purchase a new lathe, bar feeder and vacuum unloader. The ability of these three pieces of equipment to exchange data via e-Connect, an Ethernet-based communications system from LNS (Cincinnati, Ohio), proved critical to improving productivity by 90 percent on an important family of parts. The video above, produced by LNS, provides further detail about that application.

As the video shows, it wasn’t long before the company began to apply e-Connect more broadly, taking advantage of the system’s benefits to produce additional parts and part families on the new turning center with fewer change-overs. Even then, however, the company still hadn’t realized the system’s full potential. By the time I called Mr. Sander for more information about Nilpeter’s use of the system, a lean initiative was well underway, and e-Connect had proven useful in reaching some of the most important goals associated with that effort. This article, slated to run in our upcoming November issue, details how.

Related Content

-

ERP Provides Smooth Pathway to Data Security

With the CMMC data security standards looming, machine shops serving the defense industry can turn to ERP to keep business moving.

-

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

-

Increase Savings and Streamline Purchasing Operations with Amazon Business

Machine shops and small manufacturers are finding cost and time savings using Amazon Business in their shops.