Another Angle On HSM

The savings in setup time were welcome enough, but this mold maker found that a 3+2 machining center also accelerated its use of high speed machining.

High speed machining and 3+2 machining might seem like two different concepts, but at Eifel Mold & Engineering, they fit together naturally. For this shop in Fraser, Michigan, the two machining center methodologies contribute to the same goal.

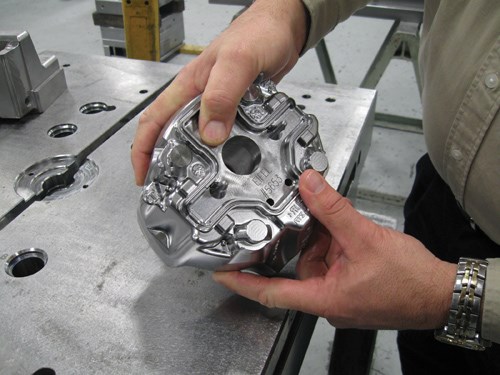

Eifel is a specialist in, among other things, molds for automotive steering wheel components. Used to produce what is arguable one of the most noticeable components of a car, a steering wheel mold typically features intricate aesthetic details and demanding surface finish requirements. On a steering wheel, even harmless imperfections stand out like striking flaws.

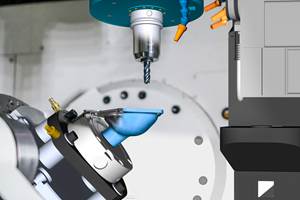

Eifel has used high speed machining for years. Fast spindle speeds let the shop use small-diameter tools efficiently, reaching into detailed areas with these cutting tools, and making small-stepover passes with them to achieve smooth finishes.

3+2 has proven to be the next step. By investing in a machining center able to freely reorient the part as needed within compound rotary axes, the shop can use high speed machining both more efficiently and more effectively. Setup time savings from 3+2 machining are considerable, but these savings are just the beginning. Now, Eifel can routinely use shorter tools in high speed machining than it typically used before. Taking advantage of the rigidity of short tools enables the shop to mill its H13 or high-hardness P20 steel even more rapidly.

Just as significantly, though, by pivoting the part, Eifel can more easily machine without visible blends. This often lets the shop meet its most exacting finish needs with minimal manual bench work after the machining is done.

Time Savings

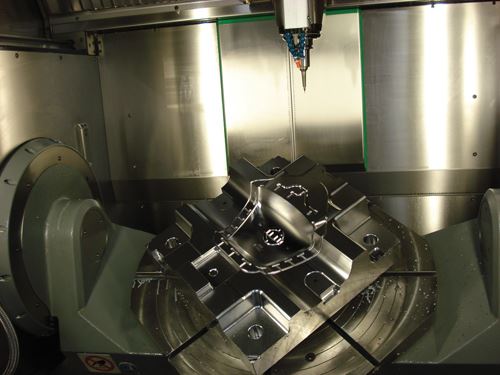

Eifel has 12 employees. Buying a sophisticated new machining center was a considerable investment. The machine the shop chose is a five-axis VMC from Hermle.

Weight capacity was one factor that distinguished this machine, says Eifel president Richard Hecker. The table (which provides the rotary-axis motion) accommodates 3,000 pounds. Some other five-axis or 3+2 machines the shop considered could pivot or rotate only much lighter parts.

While this machine is capable of full five-axis machining, the shop has used it almost exclusively for 3+2-style cutting. That is, the rotary axes are used to reorient the part, while the cutting still involves only X, Y and Z. The shop soon expects to diversify into full five-axis machining work, but so far, the 3+2 machining alone has been powerful. For mold making, Mr. Hecker says 3+2 machining accounts for at least 95 percent of the benefit that a five-axis machining center delivers.

In fact, the ability to rotate the part within the machining cycle in this way can provide time savings that are dramatic. One steering wheel mold in the recent past involved 12 hours to machine all of its necessary undercuts. At least eight setups were required to reach all these features. By contrast, running a similar mold took only two hours on the five-axis machine, thanks to the way the undercuts could all be machined in a single cycle.

Shorter Tools

Yet beyond the setup savings, another welcome payoff from this machine has been the extent to which it accelerates high speed machining. Though it was clear from the beginning that five-axis machining would enable the use of short tools, it was not necessarily clear just how important this would be.

Part of the value of high speed machining for the shop from the beginning was the way it made the use of long milling tools practical. These long tools were needed to reach the deep features of molds that otherwise required EDM. Because deflection limited these long, slender tools to light cuts anyway, the fast, light milling of HSM enabled the shop to use the tools productively.

But now, thanks to 3+2 machining (and thanks to the slim shrink-fit toolholders the shop uses with this machine), Eifel can often reach recessed features using very short tools, while th part is held at an angle. That means the “fast, light cuts” of HSM don’t have to be so light anymore. The short tool can even reach features that previously would have been considered unreachable with any tool—features that, in the past, would have been added to the mold with an insert.

Thus, 3+2 machining doesn’t just speed the machining process—it simplifies it. Standard tools alone can do a lot more.

“It gets to the point where you don’t even want to struggle with a long tool anymore,” Mr. Hecker says.

Related Content

Fearless Five-Axis Programming Fosters Shop Growth

Reinvestment in automation has spurred KCS Advanced Machining Service’s growth from prototyping to low-and mid-volume parts. The key to its success? A young staff of talented programmers.

Read MoreAutomated CAM Programming – Is Your Software Really Delivering?

A look at the latest automation tools in Autodesk Fusion 360 software and how forward-thinking machine shops and manufacturing departments are using them to slash delivery times and win more business.

Read MoreImprove Machining Efficiency Through Digital Twin Simulation

Full simulation of a machining cycle using digital twins can not only identify crashes before they happen, but provide insights that enable the user to reduce cycle times.

Read MoreIntegrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

Read MoreRead Next

Video: 3+2 Mold Machining at Eifel

A maker of injection molds for high-appearance-quality parts describes the machine tool, software and strategy this shop uses to apply 3+2 machining.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;width=860)

.png;maxWidth=300;quality=90)