June 2010 Issue

June 2010

Features

Featured articles from the June 2010 issue of Modern Machine Shop

Determining Machining Effectiveness, Not Guessing It

KitchenAid uses Overall Equipment Effectiveness to determine in real numbers the impact individual machine tools have on parts production for its stand mixers. In doing so, it brings actual machining processes closer to ideal ones.

Read More

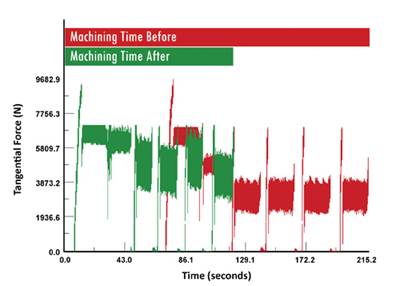

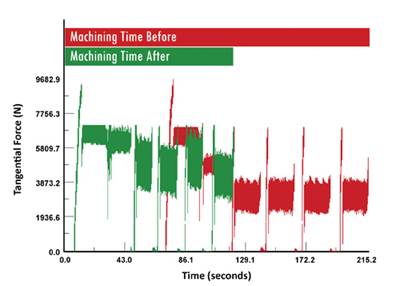

Balanced Machining Is Faster Machining

NC program optimization software initially helped Bell Helicopter’s Drive Systems Center machine titanium faster by balancing cutting forces. The manufacturer now uses it to improve cycle times for aircraft parts made from other metals, too.

Read More

Telling the Mainstream about Manufacturing

How do we reach the next generation of manufacturing employees? One machine tool company succeeds with local efforts. Meanwhile, “C.H.A.M.P.I.O.N.–Now!” seeks to go national.

Read MoreExperiencing, Crafting, Delivering

All three of these story-development steps are important, but the first one is the most significant (and it’s the one I appreciate the most).

Read More

Balanced Machining is Faster Machining

NC program optimization software initially helped Bell Helicopter’s Drive Systems Center machine titanium faster by balancing cutting forces. The manufacturer now uses it to improve cycle times for aircraft parts made from other metals, too.

Read More

Improving Machine Tool Accuracy with Volumetric Compensation

The Etalon LaserTRACER from Optical Gaging Products, Inc. is designed to make it simpler and faster to measure and compensate for changes in accuracy throughout a machine’s volume.

Read More