September 2010 Issue

September 2010

Features

Featured articles from the September 2010 issue of Modern Machine Shop

Making Research Real

Rolls-Royce expands upon a successful formula for developing manufacturing innovations beyond university research and into production.

Read More

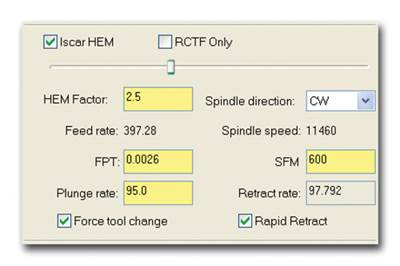

Software/Tooling Partnership Promises Easier HSM

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Read More

Composites Machining for the F-35

Lockheed Martin’s precision machining of composite skin sections for the F-35 provides part of the reason why this plane saves money for U.S. taxpayers. That machining makes the plane compelling in ways that have led other countries to take up some of the cost. Here is a look at a high-value, highly engineered machining process for the Joint Strike Fighter aircraft.

Read MoreBringing Model-Based Definition to the Masses

Designed to automate the inspection process, Master3DGage enables users to quickly and accurately verify part quality anywhere in the shop and at any stage in the manufacturing process.

Read More