October 2008 Issue

October 2008

Features

Featured articles from the October 2008 issue of Modern Machine Shop

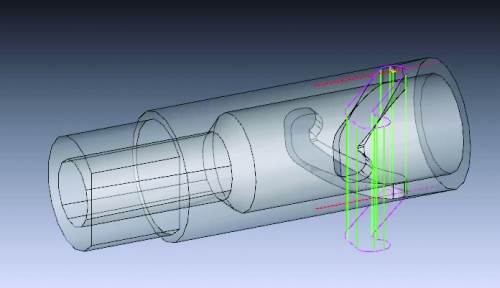

The Anatomy Of An End Mill For Aluminum

By using specialized cutter geometry and incorporating smooth finishes with tough coatings, Toolmex Corp., created an end mill well suited to cut aluminum aggressively. This tool called the "Mako" is part of the SharC line of specialized tools from the same company.

Read More

Alternate Tool Material For Hogging Large Workpieces

Shops often use either carbide or high speed steel cutting tools for hogging out the large workpieces common to the aerospace and moldmaking industries. While both materials have their advantages and disadvantages, cutting tool manufacturer Precision Cutting Tools says powder metal combines the best features of both.

Read More

Consider Swiss-Types For Medical Opportunities

Adopting the latest machining technologies is key for shops to accurately and repeatably create medical components. Swiss-style lathes offer a good combination of precision and repeatability for these applications thanks in part to their guide-bushing design, which provides support for the workpieces very close to the cut.

Read More

Keeping Things In Focus

Machine-mounted video cameras are part of a system that help a shop owner get more work done while spending less time in the shop. He can monitor and control what’s happening on his machines remotely. He’s also developed strategies for reacting to events such as unexpected tool wear or sudden tool breakage without returning to the shop to fix the problem.

Read More

Shop Aims For G Code

When rising material prices and the weak U.S. dollar contributed to a surge in demand from the mining industry, this manufacturer of rock-crushing equipment knew it had to boost productivity to keep up. Along with extensive support from trusted suppliers and an investment in new machines and cutting tools, the shop pushed the limits of its long-time CAM system to stay ahead of the curve.

Read More

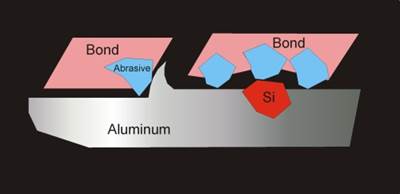

How to Hone an Atypical Aluminum Alloy

Hypereutectic aluminum used for engine blocks contains silicon particles that must be exposed during cylinder honing. This can be done using a cushioning, elastomer honing tool that allows individual abrasive particles to “bounce” over the silicon particles.

Read More

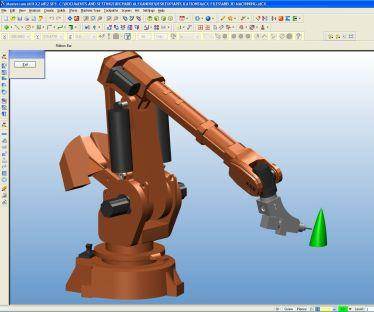

Programming A Robot The Way You Program A CNC Machine Tool

Programming a robot with the same CAM software used for a multi-axis machine tool makes it unnecessary to “teach” the robot by jogging it manually from point to point and recording these point-to-point moves as the robot’s motion commands. Robotmaster is a software package that provides this CAD/CAM-based, off-line programming for robots. It runs fully integrated inside Mastercam CAM software for CNC machine tools.

Read More

Integrating Design, Manufacturing Processes

Lack of associativity between this shop’s design and manufacturing software packages led to extra work and a high risk of introducing errors into the process. To address these challenges, the mold manufacturer implemented an end-to-end CAD/CAM package from Cimatron that ensured a seamless workflow and eliminated time-consuming manual operations.

Read More

The Basics Of Producing Big Parts

This Florence, Kentucky-based machine tool builder uses its own equipment to produce machine tools. Here’s how they succeed at big-part machining on a large five-axis machining center.

Read More