January 2007 Issue

January 2007

Features

Featured articles from the January 2007 issue of Modern Machine Shop

Cutting To The Model

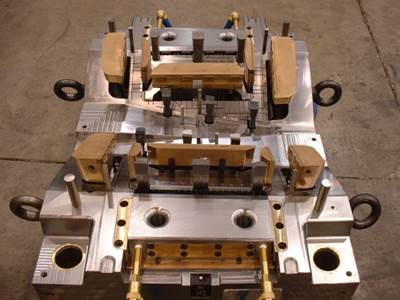

This mold shop's cutting tool strategies help it eliminate hand spotting altogether by machining complex molds directly to the CAD model.

Read More

For Mold Shops, Machining To Zero Means There Is Nothing To Hold Them Back

Advanced machining technology enables mold shops to produce cores and cavities without leaving extra stock. Following this trend of “machining to zero” will help make mold production more competitive.

Read More

Where New Machines And Methods Overshadow The Old

Eclipse Mold makes a good case for high-end machining centers as the basis for effectively machining to zero.

Read MoreWorry-Free Mold Making

A mold shop owner describes how he ensures that his shop keeps running smoothly.

Read More

24-7 Coolant Monitoring And Internet Reporting

This coolant monitoring system automatically adds chemicals to maintain recommended composition. It also automatically stores coolant data and offers shops access to customized reports at a password-protected web portal.

Read More

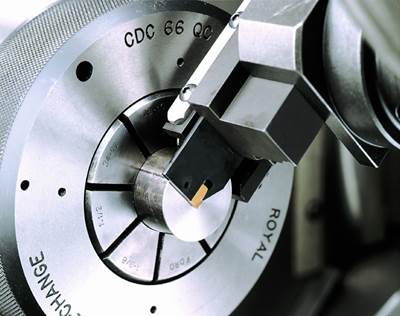

Bar Puller Basics

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. This article explains how they work and how shops can benefit from using them.

Read MoreCAM Software Is The Driving Force

Doug Noxell knew he had the right software for machining to zero, so he created a shop to add the rest of the capability.

Read MoreFrom Mold Making To Mold Manufacturing

Pro Mold had to change its entire shop culture to make the move to “net machining.” The experience made the company stronger.

Read More

Under Pressure

Using an integrated, single-window solution can alleviate programming bottlenecks, making the transition from design to manufacturing smooth.

Read More