April 2009 Issue

April 2009

Features

Featured articles from the April 2009 issue of Modern Machine Shop

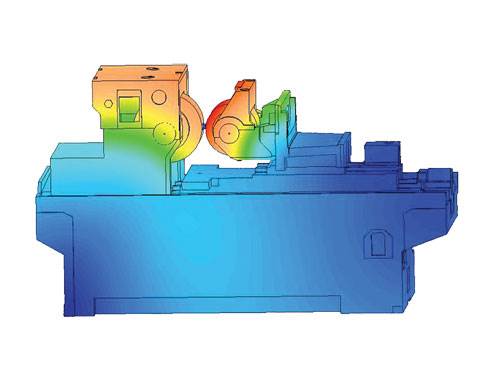

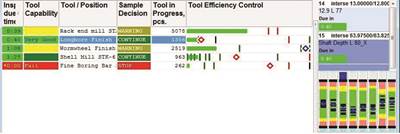

The Case For Integrated Control Of Machining Operations

An integrated software system automates a decision-making process that helps a machinist inspect parts on a timely basis, offset or change tools and appeal to engineers for improvement of process design.

Read More

Spindle Repair Simplified

This machine tool manufacturer's modular spindle design allows spindle repairs due to impact or contamination to be performed quick and easy.

Read More

Getting Credit Where Credit Is Due

Although current economic climate is by no means conducive to securing a lease or loan for a new machine or other equipment, shops with the right plan in place can still obtain the financing they need. One expert offers some advice for manufacturers seeking to obtain equipment financing amid the downturn.

Read More

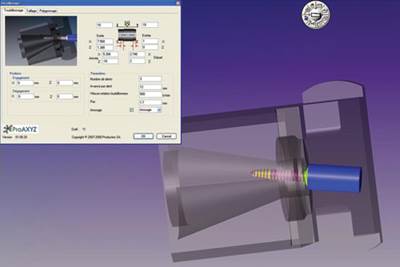

Multitasking with Enhanced Lathe Features

GibbsCAM MTM (multitask machining) now includes lathe features that are said to provide more efficiency through tool control and take advantage of newer high-tech cutting tools that turn harder materials and machine smoother surfaces.

Read More

Seven-Axis CNC Screw Machine

The UltraTurn XL seven-axis CNC screw machine with tool slides is designed for heavy forming operations for maximum metal-removal rates, the company says. The company also offers a variable-speed servodrive for live turret tooling that is only compatible with the UltraTurn. This drive will also power a live subspindle, providing two-axis ID and OD backworking capabilities.

Read More

Machine Tool Installations Grew Last Year

Survey: Once Again, China Dominates World Consumption

Read More

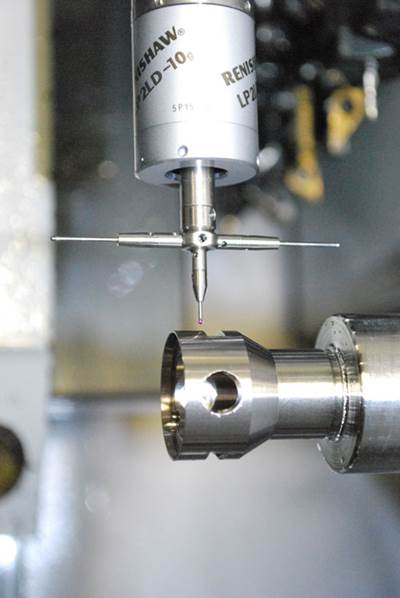

Probing Beyond Prismatic

This manufacturer has used on-machine probing to help automate setups and maintain process control for prismatic parts produced on VMCs for years. The metrology products maker recently implemented probing strategies that let it achieve similar results on its turn-mills and Swiss-types. The smaller, more economical batch sizes these machines now produce are better aligned with true production requirements.

Read MoreERP Tool for Manufacturers Facilitates Self-Customization

Global Application Builder (GAB), a programming tool that allows users to modify its ERP system to suit their specific needs, follows significant and successful customer field-testing of GAB in a variety of applications. The tool is a rapid application development language built from the ground up to integrate with the company’s One-System ERP tools. The tool allows both front-end and business logic customizations without impact to the core system.

Read More

Taking CNC To The Next Level On A Multi-Spindle

A new generation of multi-spindle automatic lathes from the Czech Republic may change the thinking about the best way to produce complex parts in small to medium volumes. An innovative drive system on these machines enables users to optimize spindle speeds for specific machining operations.

Read More