September 2005 Issue

September 2005

Features

Featured articles from the September 2005 issue of Modern Machine Shop

Connecting CAD And Measurement

This software can use the CAD file to generate an inspection program automatically, so inspection personnel don't have to spend time scrutinizing 2D drawings.

Read More

Motor Type Vs. Machine Design

On a machining center, the choice of ballscrews or linear motors may not be as important as where the motors apply their force.

Read More

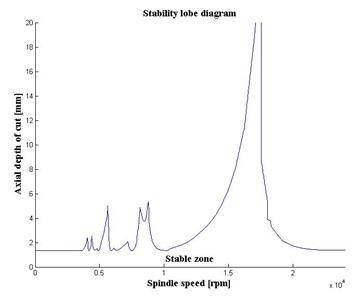

Chatter Control For The Rest Of Us

This shop finds stable milling speeds quickly using a systematic pattern of test cuts.

Read MoreMachining Centers In Motion

Special Section A collection of articles describes ideas and technologies related to moving a machining center more effectively.

Read More

Ten Questions About Chatter

If you want to use a high speed milling spindle to machine aggressively, then information about chatter should be more than just background noise. Here are some basics.

Read More

Self-Improving CNC

This control feature lets a CNC running the same part several times get better and faster with each attempt.

Read More

The In-Cycle Enabler

To achieve 144 hours per week of in-cycle time on its machining centers, this plant relies on software that offers a clear, colorful, real-time view of where the time losses are occurring.

Read MoreUnderstanding Jerk Control

What does "jerk" refer to, and where does it fit into machine performance?

Read More

How To Machine Pure Abrasion

Powder metal parts have become the darling of the auto industry, but they can be a demon for the shops that must machine the finishing touches. This shop has found that the keys to success machining such abrasive materials are proper cutting tool selection and continuous tool wear monitoring.

Read More

Adapting To A Continuously Changing Medical Market

This shop has made incremental changes to its manufacturing processes to meet the changing needs of its medical customers.

Read More

Tecumseh Sets Its Course

A very different kind of CNC software paves the way for creating an integrated manufacturing environment.

Read More

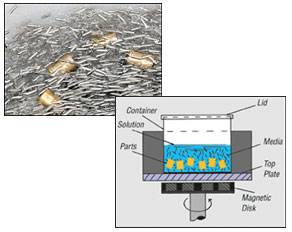

Deburr Small Parts With Swarming Stainless Pins

This deburring system uses magnetism to excite small pins that remove light burrs from small, non-ferrous parts.

Read More