May 2007 Issue

May 2007

Features

Featured articles from the May 2007 issue of Modern Machine Shop

Energy Saving Factory Automation Equipment and the Environment

The application of energy efficient motor systems can greatly reduce the overall environmental impact and cost to operate this equipment. Advancements in electric motor design and the associated drive system in modern automation equipment can be extremely energy efficient. Much of the time the most energy efficient machine will also have the highest performance but there is normally an upfront cost associated with the performance and efficiency. That added cost related with selecting energy efficient equipment may be easily returned as lowered energy costs, high performance and reliability.

Read More

Expanding The Expanding Mandrel's Usefulness

This expanding mandrel is designed to locate and hold thin-walled parts on the ID to avoid distortion during precision machining. It can also be used to hold heavy parts with large bores for heavy machining operations.

Read More

From Out Of The Lab

Disruptive technology's purpose is to disrupt the way machining is done. This article includes some of the developments to come out of the Machining Technology Laboratory (MTL), an R&D initiative dedicated to finding innovations in metalworking processes.

Read More

Vacuum Workholding Method Fits New Machining Strategy

Increased demand for armor plating components led this shop to completely revamp its machining technique. Rather than machining individual workpieces, the shop produces multiple components nested in an aluminum plate. A custom vacuum workholding system plays a significant role in this new strategy.

Read More

Workholding That Holds Off Chatter

Clamping fixtures can be part of the problem when chatter occurs in a high speed machining process. Researchers have now discovered that clamping fixtures can also be part of the solution. A supplier of integrated tooling systems has developed palletized workholding that uses a viscoelastic layer to absorb vibrational energy, thus reducing the tendency for a machining process to cause chatter. The benefits of this technology are improved surface finish, lower cutting forces and longer tool life.

Read More

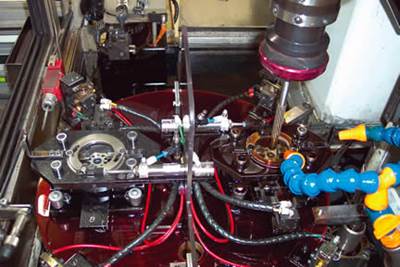

Why We Use Honing

A gear manufacturer describes the advantages it realizes by sizing and finishing bores through automated honing.

Read MoreLet's Get Fired Up

Helldoom the Bloodslurper, a set of lower teeth, a finger ring shaped like a skull and a curvy appliance handle—these were some of the objects arrayed on the countertop as part of a display at a recent trade show. The odd assortment had three things in common, the most important being a powerful appeal to the imagination.

Read More

Applying Creative Workholding Techniques

Not all parts can be fixtured by conventional workholding methods. Here are a few examples of ways that shops secure feisty workpieces for milling and turning operations.

Read More

Unattended Machining Makes Oral Orthotics More Affordable

This shop makes the oral devices that helped the shop owner and members of his family. Unattended machining is the key to making this therapy more accessible.

Read More

Boosting Machine Spindle Speed For Micromachining Applications

Small-diameter micromachining tools require very high rpm for sufficient cutting speed and material removal rates. This air spindle provides 80,000 rpm and an untethered compressed air interface to allow automatic changeovers using the machine's ATC.

Read More