July 2003 Issue

July 2003

Features

Featured articles from the July 2003 issue of Modern Machine Shop

Moving Parts, Moving Data, Keeping People

This Plant's labor-saving automation includes hardware for updating CNC offsets to adjust for gradual process changes. When the plant adopted its automated system, management thought carefully about the impact on staffing.

Read More

Cutting The Learning Curve

A grinding shop in western Pennsylvania uses self-teaching CNCs to boost productivity.

Read More

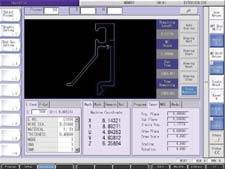

Intuitive Graphical Interface Characterizes New EDM

Another phrase for "intuitive graphical interface" would be "easy-to-figure-out pictures shown on the control screen," and that’s exactly what most distinguishes this new family of ram (sinker) electrical discharge machines.

Read More

Sourcing Automation

A new kind of 'automation project manager' helped this company install a roboticized machining cell, the first of several now operating in its plant.

Read More

The Real-World Economics Of High-Performance Drilling

To determine true cost, consider the total life of the drill.

Read MoreCounting Our Blessings

Sometimes our focus on immediate problems can make us oblivious to efforts to raise skill levels and improve the image of metalworking careers. On a recent visit to the U.

Read More

Rigid Tapping--Sometimes You Need A Little Float

One of the most common methods of tapping in use today on CNC machines is 'rigid tapping' or 'synchronous feed tapping.' A rigid tapping cycle synchronizes the machine spindle rotation and feed to match a specific thread pitch. Since the feed into the hole is synchronized, in theory a solid holder without any tension-compression can be used.

Read More