February 2015 Issue

February 2015

Features

Featured articles from the February 2015 issue of Modern Machine Shop

Getting in Touch with Optimal EDM Results

Makino’s Hyper i control for wire EDM uses touchscreen navigation in its user interface, which helps a basic user to match the productivity and capability of an experienced operator.

Read More

Cashing in Your Chips

By installing a new chip processing and coolant filtration system, this aerospace manufacturer raised the value of its scrap, slashed new coolant costs and mitigated its environmental impact, shielding itself against potential fluid disposal liabilities.

Read More

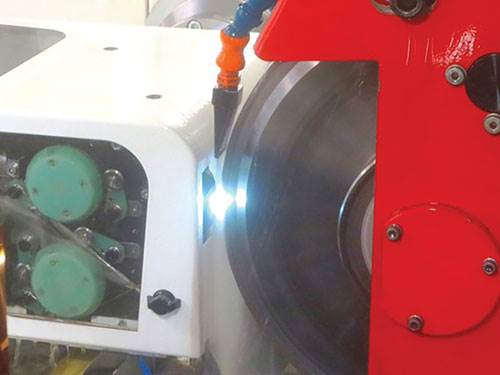

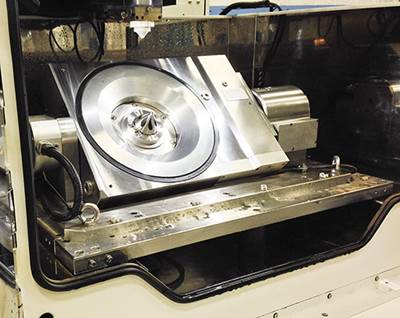

A Hollow-Access Unit for Wire EDM

By simultaneously rotating and tilting the workpiece, this rotary tilt/turn hollow-access device from Hirschmann enables the EDM wire to cut complex openings that may have different paths at the top and bottom of the opening.

Read More

A Manufacturing Road Map

This hydraulic system producer describes why and how it implemented an ERP solution.

Read More

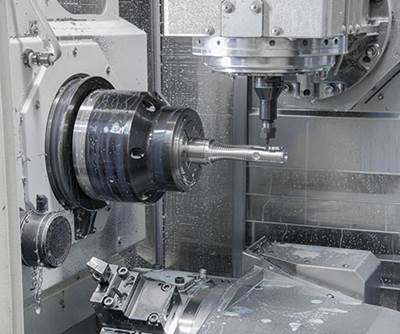

Making it in Medical

Here are the challenges that modern medical machine shops face and how they have helped shape this shop in particular.

Read More

The Foundry's Way Forward

An established supplier of short-run castings just opened and staffed a new, fully equipped, in-house CNC machine shop. Taking ownership of machining will improve the company’s range of services to customers as well as its quality control.

Read More