July 2007 Issue

July 2007

Features

Featured articles from the July 2007 issue of Modern Machine Shop

Get A (Tight) Grip

High toolholder gripping torque reduces the likelihood that a tool will slip within a toolholder during a cutting operation. A mechanical toolholder design provides a very high gripping torque via a worm gear that compresses a shallow-taper collet tightly around a tool shank.

Read More

Robots Make A Clean Sweep

A plant already effective at using robots for work handling applies robots to the end of the process as well, using them to clean and deburr intricate parts.

Read More

A Machine Designed With Contract Shops In Mind

This five-axis, moving-column machine features a table configuration allows C-axis rotation of small- to medium-sized parts as well as fixturing of very long workpieces.

Read More

Desktop 3D Scanner Captures Part Shapes

This desktop laser scanning system allows 3D objects to be digitized so that the data can be used to create part geometry for tool path generation. The system's ease of use and low cost make reverse engineering available to machine shops that could not previously access this technology.

Read More

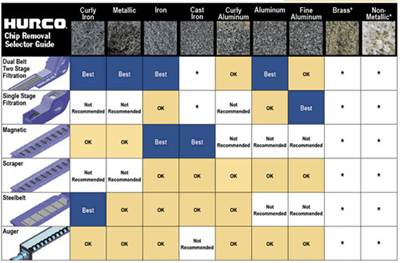

Chip Conveyor Selector Guide

A chip conveyor can dramatically reduce a machine tool’s chip cleanup time and maintenance needs. Machine tool supplier Hurco shares this matrix of the chip conveyor suggestions it gives to users of the company’s lathes. To view the chip selector guide, please see table below … .

Read More

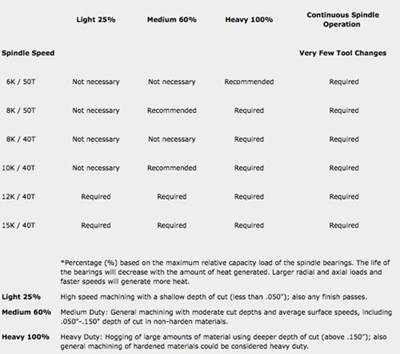

When To Use A Spindle Chiller

Because conventional spindles on machining centers are typically designed with a fixed bearing preload (no springs), there isn’t any compensation for the thermal expansion that occurs from heat generation. Higher temperatures cause the bearing raceways to expand and tighten. This causes the bearing system to increase its preload beyond the original setting, which leads to increased axial and radial loading on the bearing system.

Read More