December 2004 Issue

December 2004

Features

Featured articles from the December 2004 issue of Modern Machine Shop

Italian Offerings In Unattended Machining

From BI-MU 2004, here are a few examples of Italian companies addressing the need for unattended production and single-setup machining.

Read More

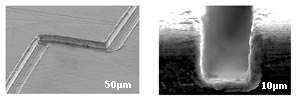

Machining Under The Microscope

Sandia National Laboratories experiments with turning and milling tools just 10 and 20 microns in size.

Read More

Redefining Multi-Spindle Machining

The premise of this mega-multi-spindle machine design is to provide a dedicated spindle for every tool required to machine a part. It proves most effective for applications in which tool change takes longer than the cutting operations.

Read More

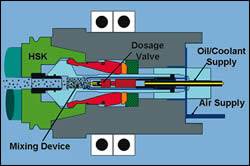

Understanding MQL

Minimum quantity lubricant can save money, improve tool life and improve the part finish. But it may involve changes to both the equipment and the processing strategy.

Read More

Getting To Submicron Accuracy

Machie tools designed for submicron accuracy and subminiature workpieces are following design strategies that depart from conventional practice. The Hyper2J from Makino is described as a case in point.

Read More

Lathe Toolholders For Turning Away

Think 'unattended machining,' and the image in your mind is probably complex - that is, some machining process that relies on automation more than the typical machining process does. But does going unattended have to involve this complexity? Instead of requiring automation, allowing the operator to step away from the machine tool might just be a matter of addressing the sources of worry that keep that operator engaged.

Read More