July 1997 Issue

July 1997

Features

Featured articles from the July 1997 issue of Modern Machine Shop

Open-Architecture CNC Closes Servo Loop In Software

The company developed Compact II, an NC programming language that quickly became one of the most widely used in the metalworking industry.

Read MoreKnow Where You're Going

Building a successful and competitive job shop business takes appropriate technology, applied well. This Swiss-type screw machine shop uses a solid strategic plan like a map to keep focused and make sound business and technology decisions.

Read MorePushbutton NC Programming

With numerical control (NC), shops learned how to automate the machining process. Now, with today's CAM software, they are learning how to automate the NC programming process.

Read More

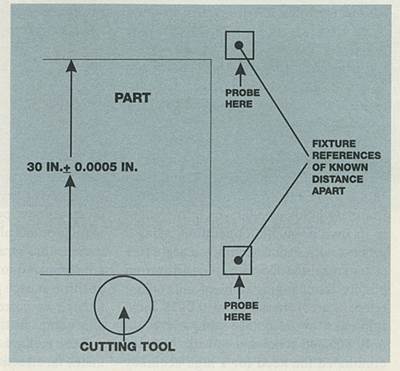

Break The Accuracy Barrier

"Reference comparison" uses probing to hold accuracies tighter than inherent process error.

Read More

High Automation for Low Volume

Many people think flexible machining cells are for high production, but this shop finds just the opposite. Here's how they've grown their cell to meet the needs of their work.

Read More