February 2008 Issue

February 2008

Features

Featured articles from the February 2008 issue of Modern Machine Shop

Multitasking With A Small Footprint

The Integrex i-150 shows how a multitasking machine for small precision parts can combine done-in-one process with a compact structure to reduce floor space requirements. Most multitasking machines for parts of this size use a second spindle for endworking of parts after cutoff. This machine uses a swing-away workholding device instead.

Read More

Smoothing Insert Surfaces Extends Tool Life

A post-coating finishing process smoothes any cracks in the outer coating of a cutting tool insert that develop during CVD and also removes droplets that PVD might leave behind. The resulting reduction in friction, heat and surface stresses is said to extend tool life and cutting performance.

Read More

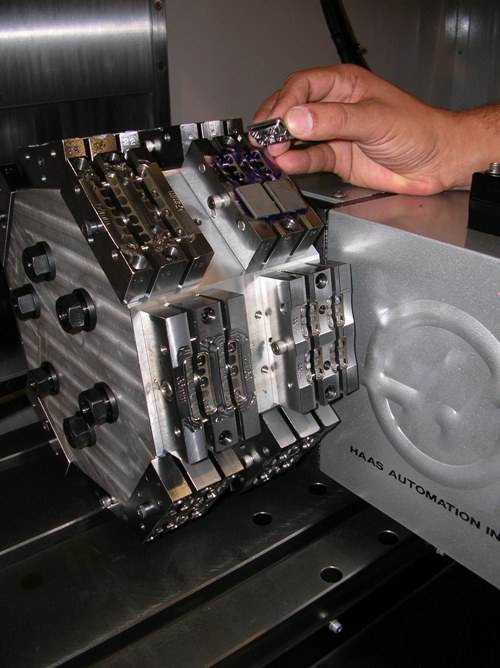

Large Wire EDM Unit Gives Shop Room to Grow

This wire EDM job shop in Wisconsin acquired a submerged cutting wire machine that lets it handle larger, taller workpieces than just about any other job shop in the country. The new machine has a “column-up” option that adds a riser block between the X-axis saddle and the Z-axis column casting to give it exceptionally tall cutting capacity. The machine was installed in November 2007.

Read More

An Alternate Route For Generating An Alternate Tool Path

A universal toolpath engine for roughing pockets optimizes cycle times by maintaining a constant material removal rate regardless of part geometry. This toolpath engine is not a CAM system. Instead, users pay a monthly fee to upload geometries to a secure Internet server and quickly receive tool paths that can be used with any CAM system.

Read More

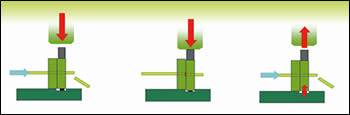

Creating Workpiece Blanks Via Adiabatic Cutoff

Adiabatic cutting is an alternative cutoff process for high-production machining applications. It uses kinetic energy to create a shockwave of sorts that softens a narrow, vertical plane through barstock material. The energy is converted into heat faster than the material being cut can dissipate it, and this controlled plastic deformation separates the material.

Read More