November 2008 Issue

November 2008

Features

Featured articles from the November 2008 issue of Modern Machine Shop

Sharing The Big Picture

The theme of visibility in manufacturing finds expression in numerous ways at this shop. One of the most conspicuous is the use of plasma displays in strategic areas to summarize the company’s performance as reported by its shop control/data-collection system.

Read More

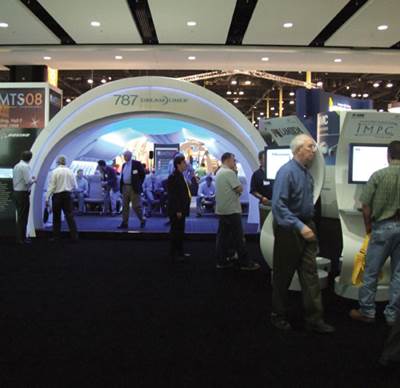

No Gloom And Doom At IMTS

September’s big show in Chicago indicated that investment in new manufacturing technology is likely to remain relatively strong despite uncertainty in other sectors of the economy.

Read More

Bryco Before and After

Within a two-month period, this Chicago-area contract shop reorganized the shopfloor, implemented new procedures and eliminated employee toolboxes. Here are the benefits the shop has seen.

Read More

Production Machining Center Integrates Rotary Transfer Concepts

A new machine platform combines CNC rotary transfer philosophy with machining center principles to offer an alternative to stand-alone production lines and flexible machining systems.

Read More

Frictionless Machining Reduces Heat, Chatter

Friction resulting from moving machine components rubbing together can create vibration and heat buildup, both of which can cause problems during machining operations. One machine from NTC America uses hydrostatic components to eliminate sources of friction for high-precision, small-parts machining.

Read More

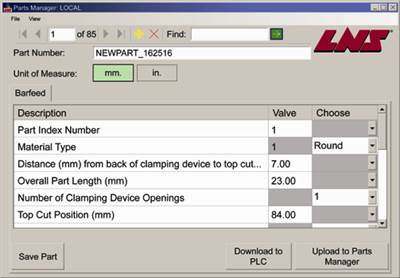

Lathe and Feeder Talk Via Ethernet Interface

Research into the connectivity and communication between machine tools and equipment like bar feeders, part unloaders, pallet systems and even high-pressure coolant systems is yielding useful ability on the shop floor. In this case, LNS uses Internet technology in its S65 bar feeder to communicate with a PC-based Fanuc CNC running a Mori-Seiki NZ2000 lathe.

Read More