December 2003 Issue

December 2003

Features

Featured articles from the December 2003 issue of Modern Machine Shop

In-House Measurement For Bi-Rotary Heads

Generally the method required to verify a four-or five-axis, bi-rotary head machining center involves sophisticated laser interferometers and time consuming machine mapping to define and correct axis deviation from wear or other causes. For most shops, this calibration is done by an outside service.

Read More

Grinding Carbide--A Niche Within A Niche

If one must pick a manufacturing specialty, grinding carbide might not be the first choice because it’s perceived to be very difficult. RPM Carbide Die, however, has worked the material for nearly 40 years and, as specializing seems increasingly to be the order of the day, this northern Ohio shop is in a good position to thrive.

Read MoreHow To Pay For That New Machine Tool

Innovative approaches to funding help shops and plants acquire the technology they need.

Read More

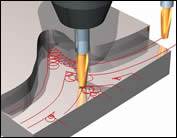

Tools For Profile And 3D Milling

Different tool shapes have different applications. Here is a look at form and function.

Read More

Plugging Into Tombstone Productivity

Customized software helps this machine tool builder maximize the output of its horizontal machining centers.

Read More

Bigger Cutters For Small Mills

This cutting tool manufacturer has developed a lighter, more compact face milling cutter that is available in 80-mm, 100-mm and 125-mm diameters for 30-taper machines.

Read More

How to Choose the Right Tool for Milling Titanium

Milling titanium is different from other metals because of the risk of heat build-up. Thanks to the metal’s low thermal conductivity, overly aggressive milling may even pose a risk of combustion. With titanium, in other words, there may be more than one reason why the cutting speed can’t be increased. And yet the speed of production still can be increased.

Read More

Optimizing The Grinding Process

R&D project aims to change grinding from an art to a science.

Read More

Multitasking For Micro-Finishing

Micro-finishing or superfinishing is traditionally a specialized secondary operation. In the shop, it follows grinding or hard turning as a last surface preparation operation. In many cases, the combination of hard turning and micro-finishing can effectively eliminate grinding.

Read More

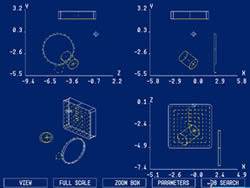

Five Sides And One Zero: Shopfloor Programming For Five-Side Parts

A five-side machining program can be thought of as five different three-axis programs stitched together. Does that mean the task of programming a five-side job has to be five times as difficult, or five times as time-consuming?

Read More

Fast Machining With Fewer Tools

Machining centers capable of precise motion at high feed rates can reduce the number of tools it takes to complete a part.

Read More