Bar Puller Basics

Bar pullers are cost-effective alternatives to enable automated turning on CNC lathes. This article explains how they work and how shops can benefit from using them.

There are multiple ways to automate a CNC lathe. If your goal is to gain lengthy stretches of unattended operation, then a bar feeder is hard to beat. Conversely, a bar puller is a cost-effective alternative for automated turning of small or medium batch sizes. That’s because a puller can free up sufficient time between bar changes to enable a single operator to tend multiple machines, measure critical part features or perform value-adding secondary operations. The resulting labor cost savings can quickly pay for the puller, according to Tom Sheridan, director of marketing for Royal Products (Hauppauge, New York).

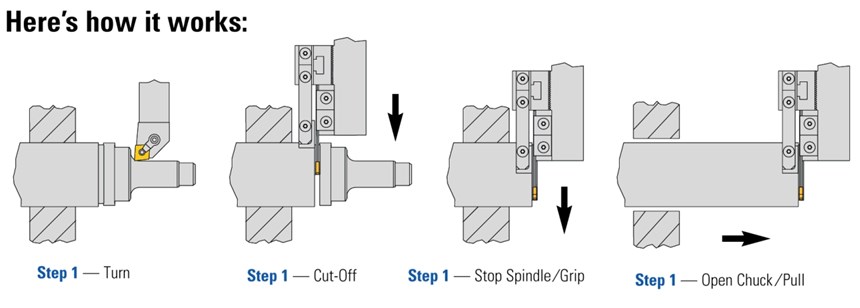

Rather than pushing a bar through a lathe’s spindle and into the workzone as a bar feeder does, a bar puller, installed in a turret station, pulls the bar out of the spindle. The lathe’s turret positions the puller to grip the bar and then retracts along the Z-axis, bringing a portion of the bar into the workzone. Once turning and part cutoff are completed on that section, the process repeats until the bar is consumed. Mr. Sheridan notes that pullers don’t take up any floor space or require an electrical interface with a lathe’s control. They also can be easily removed and used on other lathes.

So how do they “grip?” Standard bar pullers use two spring-steel fingers to provide the gripping force. During setup, the serrated jaws on the fingers are gapped a bit smaller than bar diameter (typically 1/8 inch smaller). When the jaws contact the bar, the spring-steel fingers deflect and expand over the bar. This provides the gripping force for the jaws. Similarly, heavy-duty models use internal die springs that compress to provide the gripping force. These pullers typically work with bars that are 3 inches in diameter and smaller (models with 6 1/2-inch capacity are available). They are able to grip round, square and hex barstock, and their shanks can be either round or square to work with various lathe styles.

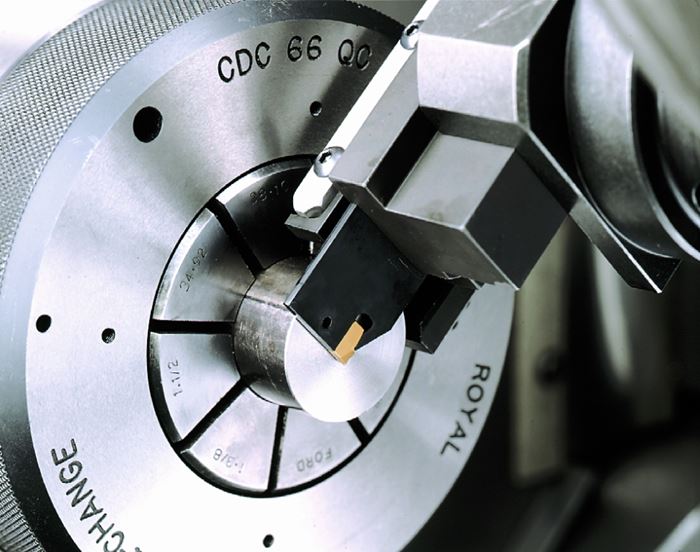

Because a cutoff tool is required after machining a portion of a chucked bar, Royal has developed a combination unit that has a cutoff tool incorporated into the bar puller. After turning is completed, the unit’s cutoff tool slices the workpiece from the bar. The unit’s puller then immediately grips the bar and pulls it into position for the next turning operation. Combining elements in this way uses only one turret station. It also eliminates the need to index a separate puller into position, which decreases cycle time.

Other bar puller versions, such as Royal’s Grippex model, use the lathe’s coolant system to provide the gripping force. Pressurized coolant actuates a piston within the puller, causing three gripper fingers with hardened inserts to clamp down on a bar. Mr. Sheridan says that 15 psi of coolant pressure is enough for these pullers to position a 210-lb bar for turning. Coolant-actuated pullers can work with a range of bar diameters—typically from 1/8 inch to 3 1/8 inches—without setting a jaw gap. The fingers will continue to close until they contact and grip the barstock. This flexibility allows the pullers to deliver completed workpieces to a parts catcher. In addition, the puller can deliver bar remnants to the catcher, eliminating possible chip conveyor damage that could be caused by a jammed remnant. These pullers can also be actuated using compressed air.

Mr. Sheridan recommends that bar pullers be used only with spindle-length bars that are fully contained within the spindle. A close-fitting guide tube or bushing should be used to support the bar within the spindle. Royal provides a nylon support bushing that fits over the bar with each puller. A bar that is unsupported by a guide tube or bushing may vibrate as it is rotated, leading to out-of-tolerance parts, poor surface finish and machine wear.

Collet chucks are the preferred workholding method when using a bar puller, Mr. Sheridan says. Because the collet expands just a minimal amount when unclamped, it keeps the bar on-center to allow the puller to make accurate contact with the bar. A wide-opening three jaw chuck may allow the bar to fall below center-line, making it impossible for the puller to grip the bar. Collet chucks also have high rpm ratings and better tool clearance, which makes them good choices for small-diameter bars typically used with bar pullers.

Related Content

Shop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreUsing Jaws as Grippers Enables Flexible, Low-Cost Automation

VersaBuilt’s automation systems significantly boosted Innovative Fabrication’s revenue. In return, the shop has helped VersaBuilt optimize its products.

Read MoreCustom Workholding Principles to Live By

Workholding solutions can take on infinite forms and all would be correct to some degree. Follow these tips to help optimize custom workholding solutions.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)