Beat The Heat With High-Pressure Coolant

In lieu of traditional flooding measures, multitasking machine operators can use high-pressure coolant strategically to improve chip control and tooling life while enhancing overall productivity.

Many turning operations can benefit from the strategic use of high-pressure coolant. In addition to improved chip control and tool life, accurately directing a high-velocity jet of coolant can improve overall productivity. One potential beneficiary of this coolant approach is the multitasking turning center. Most of these machines offer optional coolant supply at pressures between 70 to 100 bar. In fact, Sandvik Coromant has developed high-pressure coolant accessories specifically for use with these machines at that amount of pressure.

For multitasking machines in particular, inefficient chip removal can hinder the ability to make effective tool changes. Sandvik’s Coroturn HP system addresses this conundrum. In this system, each toolholder is outfitted with two to three replaceable stainless steel nozzles from which coolant is dispersed at high pressures. Sandvik says the nozzles are mounted close to the cutting edge to lower the temperature in the heat-affected zone (HAZ). They are precisely positioned and directed at a certain angle, depending upon the tool type and the intended application.

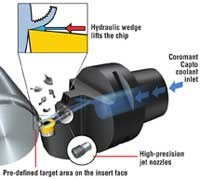

Getting the positioning just right is one of the keys to the effectiveness of this coolant-delivery technology. The system pushes away the chip and provides localized cooling of the insert at the point of contact without causing thermal shock. It does this by achieving accurate laminar flow—that is, flow in which all of the energy of the stream is focused on the work instead of being dissipated through turbulence.

This laminar flow over the top surface of the insert and the underside of the chip creates a hydraulic wedge between the cutting edge and the forming chip. As the high-velocity coolant stream quickly dispels the chip away from the insert face, it is essentially reducing the contact area on the insert. As a result, this arrangement lowers the heat and wear on the insert, as Jim Grimes, a technical specialist at Sandvik Coromant explains.

“The hot chip is no longer riding along the whole length of the insert, rubbing against the carbide,” Mr. Grimes says. “The fluid wedge in between the chip and the carbide insert acts as a buffer to keep cratering at bay.”

This wedge effect also assists in breaking chips into smaller pieces. That allows them to be evacuated from the cutting area more quickly than by traditional flooding methods. Sandvik Coromant has found this fluid wedge to be more easily applied to semi-finishing and finishing operations.

Multitasking machine operators can strategically apply high-pressure coolant to help optimize the sequence of processes. In addition to prolonging tooling life by as much as 50 percent, this coolant approach can be used as a preemptive tactic against swarf accumulation when cutting super alloys and other materials. Otherwise, the swarf can interfere with the machine’s ability to make tool changes. Moreover, because there is less heat deformation, shops can improve cutting speeds.

“The combination of the Coroturn HP effects will enhance productivity for users by allowing increased cutting data by as much as 30 percent in most cases,” Mr. Grimes comments.

In short, deviating from the traditional method of flooding the machining zone with coolant in turning applications can pose various benefits. However, shops should resist the urge to view more effective coolant delivery as a panacea.

“Don’t use this to try to compensate for other shortcomings of factors such as an unsuitable insert, instability or incorrect cutting data,” Mr. Grimes concludes.

Related Content

STLE Opens Registration for 2024 Annual Meeting

The Society of Tribologists and Lubrication Engineers’ 2024 STLE Annual Meeting & Exhibition will take place May 19-23 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Read MoreMaster Fluid Solutions Semisynthetic Coolant Inhibits Corrosion

Trim MicroSol 685XT is designed to provide enhanced corrosion inhibition on all ferrous and nonferrous metals.

Read MoreHennig Inc. Acquires Industrial Coolant Systems

ICS develops and field tests high-pressure coolant systems, coolant filtration systems and other machine tool solutions.

Read MoreVomat Coolant Filters Provide Precise Temperature Control

The company’s filters ensure a continuous supply of clean oil for microtool grinding applications.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More