CAM Suite Promotes Die Throughput

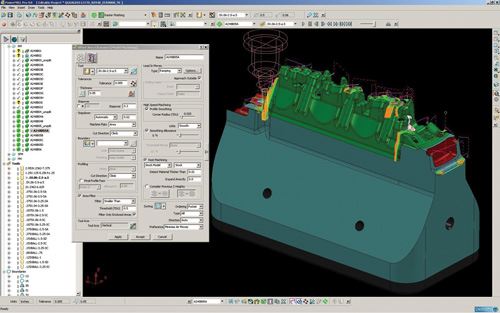

This automotive tool and die manufacturer had determined that remaining competitive would require reducing machining times. However, the impediment to throughput lay not in the machining end of the operation, but rather in the time spent programming complex tool paths. With fast calculation capability and a variety of strategies for five-axis roughing and finishing operations, Delcam’s PowerMill CAM package reduced programming times and enabled faster, more efficient machining.

Lengthy programming times and inefficient toolpath strategies can more than offset productivity gains derived from even the most high-tech machine tools. That was the case at Exco Engineering, a Newmarket, Ontario-based manufacturer of high-pressure dies for engine blocks, transmission cases, instrument panels and other automotive industry components. While a range of the latest CNC machining centers, large boring mills and CMMs were sufficient to ensure the accuracy and functionality of the dies, generating tool paths for creating complex cavities in H-13 steel was by far the most time-consuming task in the shop. By replacing its several different software brands with the PowerMill CAM package from Delcam (Salt Lake City, Utah), Exco realized a threefold increase in productivity on some parts.

The company chose PowerMill after a 6-month evaluation period, during which it consulted with six leading CAM software developers to determine which solution would best meet its needs. In addition to more quickly defining tool paths, the company sought to increase flexibility for faster turnaround of new programs and more efficient processing of engineering changes. Other goals included reducing time spent on toolpath verification and reducing cycle times.

According to the developer, PowerMill features an easy-to-use interface and fast calculation times. In addition, comprehensive gage and collision checking is performed automatically during toolpath calculation, a feature not available with the shop’s previous software. Toolpath editing is also faster because programmers can delete part of a path while leaving the rest intact. By contrast, the company says its previous CAM packages typically took 5 to 10 minutes to process program changes, depending on the size of the file. Another helpful tool for programmers is template creation, which allows unattended processing of multiple tool paths on similar part configurations. This saves time in programming and ensures consistency, the company says. Since implementing the software, programming time at Exco has been reduced by half.

Programming time savings have translated to increased productivity on the machining end of operations as well. Typically, the die machining process includes roughing, heat treating and finishing operations. Exco uses five-axis machines to reduce setups and to provide more efficient cutting angles that allow more material to be removed with each pass. According to the company, one primary advantage garnered from PowerMill is the flexibility provided by a variety of toolpath strategies for both five-axis roughing and finishing. In addition to providing a number of options for more quickly tackling a job, many of these strategies result in less tool wear and improved part quality.

Roughing strategies include machining to or from a point, orientation through a line or curve, and programming using a reference surface. One strategy that has been particularly beneficial at Exco is the use of spiral tool paths, which minimize air moves to reduce machining time. In addition, spiral tool paths result in a more consistent load on the cutter, limiting wear and potential for tool damage.

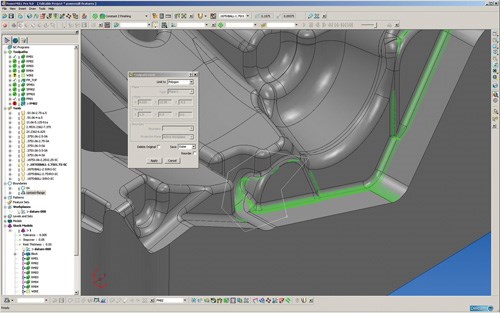

In fact, the CAM package orders tool paths in a way that reduces air moves for all roughing strategies. This makes the ordering of rest-roughing tool paths particularly efficient. By completely removing material left by previously used, larger tools, these rest tool paths reduce cycle times because they allow re-machining only on areas that require a smaller cutter.

PowerMill also allows the company to take full advantage of cutter designs that enable taking deep passes with the side of the tool. In this strategy, known as raceline machining, tool paths become smoother and more rounded as they move outward from the eventual part form. In addition to enabling faster machining by minimizing sudden changes in direction, this reduces wear on the cutter and stress on the machine tool, the developer says.

PowerMill’s collision avoidance feature also improves the efficiency of roughing operations by allowing programmers to cascade down with a shorter tool assembly. This enables cutting more area without the need for a larger tool. Along with the toolpath strategies mentioned above, this enables the company to complete some roughing operations in about a day—a vast improvement over the company’s previous software, which often required programmers to spend as long as a week to program tool paths.

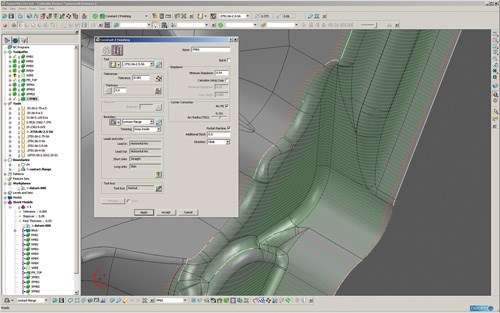

Finish machining strategies include parametric offset machining and three-axis swarf machining. Parametric offset machining ensures that the number of tool paths used over a surface of varying width is kept constant. Rather than stopping and starting some paths, the step-over between tool paths varies within preset limits. This approach is said to provide better surface finishes because it avoids sudden changes of direction that can leave marks on the surface.

Three-axis swarf machining is used to finish vertical walls with the side of the tool. According to the developer, this results in a smoother surface finish than cutting walls in a series of operations at different Z levels. The software has also improved corner machining, Exco programmers say. That’s because the software allows them to specify a corner correction radius that helps the tool move through more smoothly.

Also, PowerMill enables the shop to perform semi-finishing, an operation that required too much additional programming time with the previous software. Now, programming semi-finishing operations takes nearly 90 percent less time while providing measurable cost benefits. By leaving a more consistent stock condition, semi-finishing enables more efficient finishing operations, reduces the risk of tool deflection and wear, and allows increased feed rates. Key features enabling semi-finish programming while still reducing machine cycle times are residual area machining using a stock model, in which the software automatically limits tool paths to areas previous tools could not access due to their size, and corner correction, which enables faster feed rates when tools do not fit into corners.

"In fact, semi-finish machining actually speeds up our finish machining programming time," says one Exco programmer. "That’s because we no longer have to include areas of heavy material removal, eliminating the risk of overloading a tool. This allows us to use a larger variety of toolpath strategies, including a few we might not have considered effective before because heavy cutting might have caused premature tool wear, shanking out or even breakage."

Compared with the shop’s previous CAM applications, the software provides better control of material removal rates at each stage of the process. Tool life has improved and programs run faster. Exco programmers say implementing PowerMill has resulted in a more efficient, safer die production process that takes less time, reduces tool costs and yields higher-quality results.

Related Content

TTI Brings Specialty Gear Production In-House with Multiaxis Machining

By investing in a 3+2-axis machine and utilizing simulation software for diagnostic checks, Techtronic Industries turned a four- to ten-week lead time into a one- to two-week lead time.

Read MoreLarge-Format Machining With Small Cutting Tools and Dynamic Motion

Napoleon Machine, a defense contractor that provides parts for the M1 Abrams tank, recently took advantage of a CAM feature that allowed the company to streamline its cutting strategies and program offline. Here’s how the shop cut cycle times nearly in half with its large-format five-axis machining operations.

Read MoreGrinding Simulation Enables Growth in Custom Tooling

Simulation software both streamlines Gorilla Mill's grinding machine setups and speeds up the company's tooling design and verification processes.

Read MoreIntegrated CAD/CAM Promotes Process Efficiency, Traceability

High-requirement markets are not only searching for good parts — they're searching for proof of good parts. CAD/CAM software can help.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More