CAM System Simplifies Tire Mold Programming

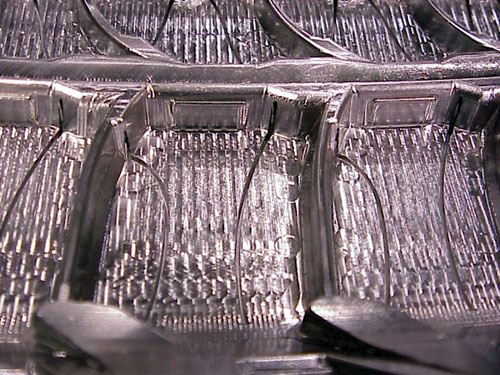

PROBLEM: Segmented tire molds required complex, time-consuming programming SOLUTION: HyperMill CAD software from Open Mind RESULTS: Improved delivery time, part quality Chris Sipe, owner of Northeast Tire Molds in Akron, Ohio, likens machining tire molds to evolutionary theory—while some firms go out on a

Chris Sipe, owner of Northeast Tire Molds in Akron, Ohio, likens machining tire molds to evolutionary theory—while some firms go out on a branch and never go any higher, others can look a little further down the road and adapt to changing conditions. Mr. Sipe says his company is one of the latter. Having machined tire molds for more than 30 years, Northeast has moved from the traditional model of machining two-piece tire shell molds from castings to machining segmented molds directly from aluminum stock. Business has doubled during the past 2 years as a result.

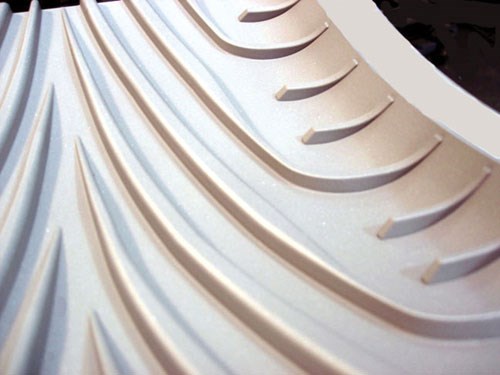

A key component of this transition was hyperMill, a CAM package developed by Open Mind Technologies. Tire molds are extremely complex, with numerous 3D contours and cavities, and this creates a significant programming challenge. In his evaluation of the software, Mr. Sipe found that one programmer using hyperMill required only 3 months to accomplish the same amount of work that took a year with the company’s previous system. Along with an investment in the simultaneous five-axis machine tools and associated tooling needed for such work, the software has enabled Northeast to provide higher-quality products and faster delivery.

For many years, the standard in tire manufacturing has been two-piece shell molds. Uncured (or “green”) tires consist of layers of inner liners, tire cord fabrics, steel, Kevlar and extruded rubber. The green tires are placed into a press where the upper and lower mold sections meet. Heat energy creates chemical reactions to cure and bind the rubber, steel and fabric layers. Meanwhile, pneumatic bladders inflate to expand the tire against the mold and impart the tread design and required sidewall engraving. Post-press requirements can include dimension checks, X-ray inspections and other section analysis.

However, deforming and shaping a green tire within the contour of a two-piece mold can cause the rubber to move, affecting thickness conformity throughout the tread. On the other hand, segmented molds consisting of 7 to 10 sections with separate sidewall plates can decrease this movement and improve overall tire performance. The downside is that segmented molds take longer to cast, machine and finish, significantly increasing costs.

Although direct-machining techniques debuted in the 1960s, the process was complex, time-consuming and expensive. The advent of five-axis machine tools and 3D CAD models excited many mold builders, but significantly attacking lead time remained a struggle. “Tire molds require a very high standard of five-axis simultaneous methods,” says Mike Christie, Northeast Tire Molds vice president and a 15-year veteran of the company. “We believed in the idea of eliminating castings and direct-machining tire molds from stock, but unfortunately, the programming efforts were immense. And with segmented molds, the same problems repeated themselves in many locations.”

To eliminate castings, Northeast needed simultaneous five-axis machine tools, tooling and programming capabilities that would allow it to machine the molds directly from stock. Procuring such a package, however, took years of education and experience. “We wanted to be self-sufficient,” Mr. Sipe says. “We didn’t have a foundry, and we couldn’t control our costs with outside vendors, so we sought capital equipment where the model didn’t matter.”

Mr. Sipe found one piece of the package at the 2001 EMO show in Hannover, Germany: a five-axis Alzmetall milling machine. “You could purchase three other five-axis machines for the price of one Alzmetall, but you’re not getting three times more capacity,” he says. By 2005, he was ready to take delivery, but not without the programming wherewithal.

One advantage of segmented molds often touted by tire makers is that if a particular tread problem exists, they can correct one segment without recasting the entire mold. However, Northeast found itself writing its own lengthy routines to repeat programs in various mold locations. The company tried to use the same five-axis CAM software used by one of its major customers, but the results were a “nightmare,” Mr. Christie says. All data, including intermediate results, went into one big file, which frequently became too large to handle correctly. Programmers often found themselves waiting a half-hour or longer just to open files.

Believing it had a state-of-the-art system, Northeast gave itself 9 months to learn the programming before taking delivery on the new five-axis machine. Still, the company made little progress. “We were told by experienced people what we could and couldn’t do,” Mr. Christie says. “The amount of time invested to get the end result was astronomical.”

Faced with these difficulties, Mr. Sipe recalled talking to Open Mind Technologies at EMO 2005 about tire mold programming. When he decided to evaluate hyperMill, Open Mind’s CAM system, he found it had a number of advantages over the company’s current system and decided to implement the software in the shop. “We had automatic indexing and collision checking, which we didn’t have before,” Mr. Christie says. “We were able to model the entire machine in hyperMill, and everything is interrelated. Our old package wouldn’t let us check back.”

The software also can quickly handle the large amount of data, and it enables parametric modeling through CAD interfaces. Other features include global swarf machining; stock trimming and stop surfaces in five-axis strategies; associative programming; automation through macros from 2D to five-axis in the same package; and 2D through five-axis program generation via the same postprocessor.

In addition, the software offers a tire-specific package in which all 2D, 3D and five-axis strategies are expanded by a parameter that allows the user to assign a pitch to each machining strategy. This makes segments composed of a specified pattern of pitches easier to produce. Automated segment generation not only assigns NC tool paths to the corresponding mold segments, but also adjusts tool paths that go beyond segment boundaries.

With the right machine tools, tooling and programming support, Northeast Tire Molds is now reaping the rewards of multitasking. The shop has moved from performing as many as eight operations on various machines to loading raw material and proceeding to the finished part on a single machine with no subsequent benchwork. For an average tread, the company can deliver a mold in the time it used to take to get the casting. Mold quality has also proved. “Customers find their molds are lasting longer, and the quicker delivery time means we have more time for testing new things,” Mr. Sipe says. “Business has doubled in the last 2 years, and the amount we’ve advanced in the last 6 months makes it very exciting to envision next year.”

Related Content

Hexagon Acquires TST Tooling Software Technology

Hexagon acquires TST Tooling Software Technology, a distributor of VISI, Hexagon’s CAD/CAM software for the mold and die sector, and PEPS CAM software.

Read MoreYCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Read MoreTwin Spindle Design Doubles Production of Small Parts

After experiencing process stalls in the finishing stage of production, Bryan Machine Service designed an air-powered twin spindle and indexable rotating base to effectively double its production of small parts.

Read MoreStars Slowly Align for Small Shop Merger

RPM Tool’s seemingly overnight expansion from a five-person machine shop to an almost 30-employee production business involved over a year and a half of planning.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)