Continuous improvement efforts can sometimes spur a shop to revisit a machining process or strategy it had previously put aside. Tracey Gear and Precision Shaft recently did this when it reconsidered the way it programs its turning centers.

When the Pawtucket, Rhode Island, manufacturer of gear and shaft components adopted NC lathes decades ago, it found that programming them with CAM software made the most sense. Yet as the shop began integrating CNC turning centers with intuitive conversational controls, it moved away from CAM as its primary means of programming. By creating part programs at the CNCs, machinists could take full responsibility for their work and didn’t need a dedicated CAM programmer to create part programs for them.

Doug Tracey, the company’s vice president of engineering, says that while this strategy worked well for the shop for a number of years, it had an unintended consequence. As Tracey Gear began replacing its older NC lathes, it purchased CNC turning centers from different manufacturers, each offering a distinct conversational control. This wasn’t necessarily problematic for new jobs, because operators would simply create part programs on the most appropriate turning center. But doing so essentially tethered jobs to specific machine brands. That meant repeat jobs would have to be sent to the same turning center for which they were originally programmed. Otherwise, a new program would have to be created to enable a repeat job to run on a different brand of machine.

By hamstringing the shop’s scheduling flexibility, this situation created delivery challenges due to the unpredictable nature of its customers’ needs. In fact, Tracey Gear’s lathe department had become a production bottleneck, which was a significant dilemma because approximately 90 percent of the shop’s work requires turning operations.

This spurred the company to revert back to CAM a few years ago as its primary method for programming turning centers so part programs could again be used on various machine brands. This time, however, the shop trained all of its machinists to become CAM programmers. Like programming using conversational controls, this gave them full ownership of each job. As a result, the shop improved its scheduling flexibility, has made greater strides toward implementing paperless shopfloor processes, and even created a much-needed expediting service for customers needing gears and related components in short order.

Programming Evolution

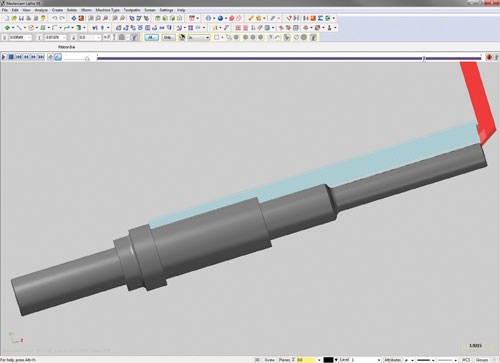

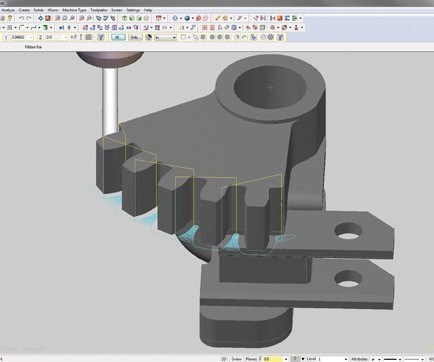

Tracey Gear specializes in manufacturing shafts; sprockets; and spur, bevel, helical, spline and worm gears for elevators, aircraft, food processing equipment, postage metering machines and various other applications. The shop’s 10 CNC turning centers and three machining centers create blanks that are sent to its dedicated gear-cutting equipment.

Tracey Gear was introduced to NC lathes in 1987 after purchasing a nearby business that used such equipment. It bought its first seat of Mastercam CAD/CAM software from CNC Software at that time. This software enabled programming a job once and using it on any of the shop’s NC lathes (after an appropriate postprocessor was created). This remained the shop’s primary programming method until approximately 12 years ago, when it began installing CNC turning centers with conversational controls.

Mr. Tracey says the transition to programming at the machine was initially helpful because the lathe machinists fully owned their projects. However, processing repeat work became problematic. That’s because a machine could become overloaded with work in queue if it was the one originally programmed to run a repeat job(s) in the first place.

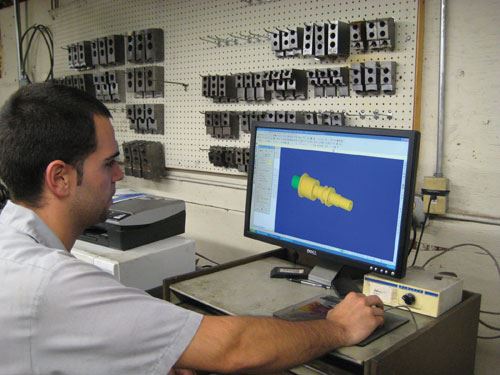

In 2009, the shop began shifting back to using Mastercam as its primary means of programming turning centers. The shop had maintained licenses for both Mastercam Lathe and Mastercam Mill over the years, so it already had access to the latest versions of the software. Therefore, the transition to shopfloor programming using Mastercam involved customizing postprocessors for the various turning centers, training machinists to use the software and purchasing computers that could be used to run the software on the shop floor.

Mr. Tracey says Mastercam reseller Cimquest was key in providing machinist training and developing postprocessors. He appreciates how Cimquest engineer Steve Biehl encouraged trainees to bring in prints of actual parts Tracey Gear produces, which enabled him to tailor classes to match the company’s specific programming needs. Rather than overwhelming trainees with every software capability, Mr. Biehl focused on the functions the machinists would use on a daily basis. This not only reinforces essential programming concepts, but also enables trainees to hit the ground running back at the shop because it minimized the inherent programming ramp-up period.

Mr. Biehl also created a number of customized postprocessors for the shop. Those postprocessors have evolved over the past few years to better meet Tracey Gear’s production needs. Machinists contact Mr. Biehl when they want to modify a postprocessor to cause a machine to behave differently. He then logs onto Tracey Gear’s server remotely and makes the requested postprocessor modifications with minimal, if any, disruptions to the shop’s workflow. These modifications have included refinements such as eliminating unnecessary machine moves, and shutting off the coolant and rapidly bringing the table to the machine doors as soon as the last operation is completed. While some of these changes only marginally increase machining efficiency, they add up over time, Mr. Tracey emphasizes.

CAM Benefits

In making the move back to CAM as its primary programming method for turning centers, Tracey Gear has benefited in a number of ways. Here are a few examples:

• More flexible scheduling—Even though Tracey Gear is a relatively small company, scheduling still can be challenging because jobs follow different paths across different machines. Because virtually all jobs require saw cutting and turning, it’s important to get parts scheduled and processed in the right order so they can efficiently flow to the gear cutting equipment. CAM programming provides greater flexibility because a single program can be written and sent to any number of turning centers. Part programs are stored on a server, and the shop performs daily tape back-ups as well as Carbonite back-ups of those valuable programs.

• Expedited services capability—Because greater scheduling flexibility enables Tracey Gear to better handle customers’ “hot” jobs, the shop has been able to establish a new company division called Express Gear. Mr. Tracey says the shop had been hoping to create this for a while because customers with vital equipment in need of repair often request extremely fast component delivery. Until now, Tracey Gear was never in a good position to do the sort of quick-turnaround work to accommodate such requests. Flexible scheduling enables the shop to quickly look at the upcoming workload for specific machines and insert hot jobs into the schedule where it is most convenient. Mr. Tracey likens this to the postal service, in which customer rates depend on how fast components must be delivered. The shop’s normal delivery time is four to five weeks, but the Express Gear service can get parts to customers in as little as two days.

• Paperless processing—Tracey Gear currently has a number of file cabinets that contain old hand-written setup sheets. However, the switch back to CAM programming is bringing the shop’s goal of going to a paperless process within reach. In fact, once machinists realized why the use of CAM was so important, they took the initiative to design a digital template for setup sheets. The standardized setup sheets ensure that all relevant information and instructions for repeat jobs can be readily deciphered by anyone on the shop floor.

• Hiring operators, not just machinists—In the past, Tracey Gear primarily employed skilled, well-trained machinists who were capable of creating part programs using conversational controls. CAM programming has enabled it to create a better mix of machinists and machine operators. Today, machinists program jobs and set up machines, leaving operators who lack shopfloor experience to run production. These operators are typically younger employees, some of whom are fresh out of high school, and the shop can bring them in at a lower pay scale. However, the shop strives to give these operators the chance to progress to positions of greater responsibility, including creating part programs using Mastercam.

• Approaching new equipment purchases in a new way—Mr. Tracey says his shop is looking to add more advanced machine tools to leverage the capabilities that CAM programming offers. These include turning centers with live tooling capability, turning centers with two turrets and four-axis machining centers. The shop is also looking to Mastercam as a means to get more out of its CNC grinding machine and help pave the way for EDM, which the shop considers a good complement to its existing equipment.

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)