Can a CNC M-Code Accelerate Laser Calibration?

A metrology technology supplier describes a technique for significantly reducing the downtime to calibrate large machines.

Laser calibration of a machine tool hardly proceeds at light speed. For example, bi-directional laser calibration of just one 40-inch axis of a CNC mill might take the better part of an hour, with the machine axis moving in 10-mm increments and stopping to settle as the laser interferometer takes each reading. That pause for each reading can be as long as 23 seconds, says Renishaw, a supplier of machine calibration technology including laser systems. The cumulative effect of all of these little waits can translate to considerable downtime for calibrating a large, high-value machine tool. In some cases,—depending on machine crashes and the shop’s quality system, the company says—a critical machine might be out of action for several days per year just for this calibration. Owners of these machines are obviously very aware of the lost production.

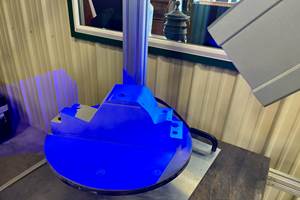

But there is a solution, Renishaw says. A technique taking advantage of a feature in its XL80 laser interferometer reduces the settling time to just 250 milliseconds after each incremental axis move, cutting calibration time by 85 to 95 percent. In addition to returning the machine to production more quickly, this technique also better reflects axis positioning accuracy under real cutting conditions, because in real cutting, the moves are fast and the settling time is slight before the tool engages the work.

Quality Tech Services of Byron, Georgia, uses this time-saving technique with the XL80. The company has instructed new laser buyers on using it as well. Company owner Mike Schraufnagel says, “As a calibration service, the first concern we hear when we walk in the door is downtime on a machine. Customers will do anything to cut downtime on a critical asset.” His customers who own lasers themselves have employed this technique to keep their machines cutting, while his own team uses it to increase its overall efficiency. “What normally would take 30 minutes now takes just 3,” he says. “In one afternoon, we were able to complete six laser setups and three ballbar setups on a machine in 2 hours.” In the past, this work would have taken at least a day.

An M code and an open contact relay are the prerequisites that make this technique possible. To achieve the high speed calibration, the machine’s CNC uses an available M code to close a “normally open” set of relay contacts for between 10 and 20 milliseconds. If the M code to effect this trigger is not available, it might be available for purchase or activation through the OEM. Closure of the relay contacts via an auxiliary I/O cable provides a trigger for the laser to record the difference between the measurement reading and the target position.

“We identified spare relays that can be controlled via M codes on a Haas CNC machine in our lab,” explains Michael Wilm, Renishaw’s calibration business manager. Using the relays to trigger the laser interferometer and thereby reduce machine downtime was the idea that developed from this discovery. The laser simply needs to see the relay close for as little as a microsecond, but mechanical relay contacts can bounce for the first few milliseconds, he says. Therefore, “we have added a bounce rejection feature programmed into the electronics of the laser. Any chatter within 20 milliseconds gets ignored, the laser takes a reading, and the axis moves to the next measuring position.” The result is laser calibration that proceeds quickly, and more like the way the machine will move during normal production.

Related Content

How to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreA Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read More5 Things CNC Operators Must Know About Sizing Adjustments

For CNC operators, sizing adjustment is an essential skill. Keep these points in mind when training new CNC users.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)