Changing the Landscape of Gear Production

The convergence of innovative cutter designs, five-axis multitasking machines and capable software is revolutionizing small- and medium-batch gear production.

InvoMilling is the name of a proprietary gear milling process developed by cutting tool manufacturer Sandvik Coromant with the cooperation of machine tool builder DMG/Mori Seiki. This process enables a five-axis multitasking machine to produce gear-tooth geometry with off-the-shelf tooling. By virtue of new programming software, the tool path, not the shape of the cutter, determines the gear profile. Because a tool path can be reprogrammed quickly, the same cutter can produce an unlimited number of gear profiles within a certain, but rather wide, range. No additional cost or added time to change from one profile to another is involved.

This capability makes the five-axis multitasking machine the ultimate in flexible gear cutting technology. This is a huge benefit to two classes of potential users. Shops that specialize in gear production can extend their services to customers requiring small batches of high-quality gears, or even single prototypes, at a very attractive price. Likewise, general machining companies and job shops can add enhanced gear cutting to their range of machining operations, expanding the types of parts and part features they can handle.

This development changes the landscape for gear making. Shops that never made gears now have a clear path of entry into this business. Shops that have always made gears now have a clear path to grow this business by doing more for existing customers while attracting new customers with additional offerings.

A Breakthrough Development

Until now, gear production has been restricted by three severe limitations. It usually required dedicated tooling such as a gear hob or special form tool suitable for only one size gear. It required single-purpose, dedicated gear-producing machines with sufficient torque and rigidity for the application. Special programming and operator skills were also generally required.

InvoMilling overcomes all three of these limitations. It uses a standard, multi-purpose turn-mill machine; disk-shaped milling cutters with standard carbide inserts; and easy-to-learn conversational programming routines.

Most shops implementing this process will have to make additional investments to acquire InvoMilling capability. For example, shops considering the acquisition of a new multitasking machine might find the option of adding gear production using this process a compelling incentive to invest in a DMG/Mori Seiki NT turn-mill center. (Currently, DMG/Mori Seiki is the only builder licensed to use this process.) However, Nitin Chaphalkar, manager of advanced solution development at DMG/Mori Seiki, notes that multitasking machines are capable of not only InvoMilling, but also traditional hobbing and gashing processes. “This fact means that users of multitasking machines now have the choice of several effective ways to make gears,” he says.

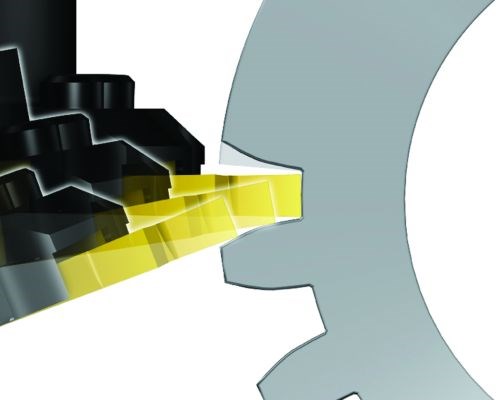

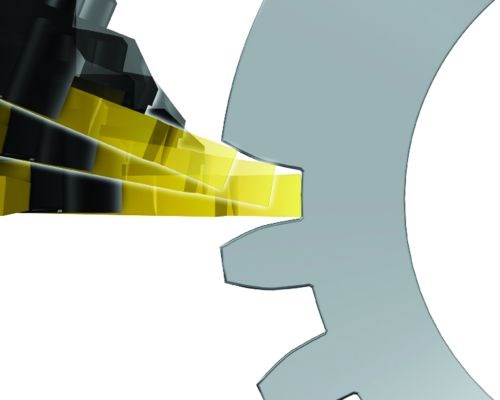

The name InvoMilling represents a new concept in involute milling that is an alternative to the specialized hobbing process. It is a combination of slot milling and multi-axis turn-milling. Simultaneous motion of the X and B axes or with the Y and B axes enables the milling cutter to follow an involute path. Simply changing the tool path results in unlimited gear shapes producible with the same cutter. Sandvik Coromant has developed three disk cutter sizes (CoroMill 161, CoroMill 162 size 4 and CoroMill 162 size 6) to cover the range from module 2 to 12 or 12 to 2 DP (diametral pitch). Gears with any helix angle—both involute and noninvolute profiles—can be produced with the same tools.

Multi-Purpose Flexibility

Eliminating the need to stock individual hobbing tools, which are costly and involve a long leadtime to acquire various gear sizes, is one of the important advantages of this process. “A gear manufacturer usually has a large inventory of dedicated tools. There’s one hob or gasher for each diametrical pitch size of gear. Even with a huge inventory, it still may not be enough,” Nicklas Bylund, InvoMilling project leader at Sandvik, says. “You have to place an order when you don’t have the right tool. If you have InvoMilling, three tools will cover you from DP2 to 12, so much less tool inventory is required—that’s revolutionary.”

When gear-cutting cycle times are compared between hobbing and InvoMilling, hobbing is sometimes faster, depending on the size of the gear and number of teeth. However, the overall efficiency, flexibility and economy of InvoMilling clearly favor this process for gear production in smaller batches. “With InvoMilling, the actual cycle time for the gear part is comparable to a HSS hob, but you need to calculate the whole time from the hob being ordered to being delivered, which can be months,” Dr. Bylund explains. “With InvoMilling in place on a multitasking machine, you can just program it and do it, often on the same day. This is a paradigm shift for flexible gear production.”

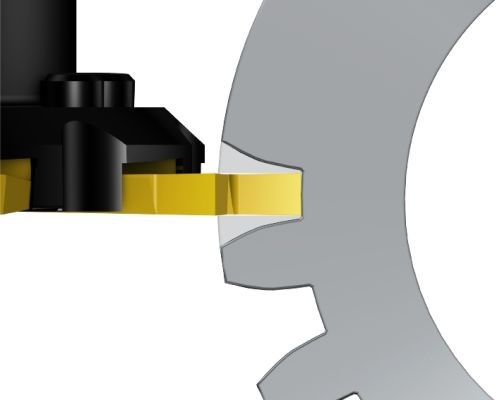

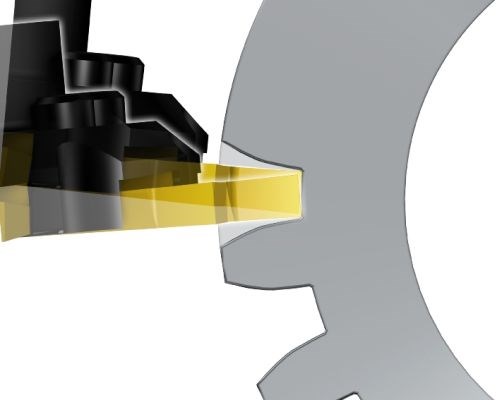

InvoMilling involves several machining steps. In the first step for an outer spur gear, for example, the disk cutter performs like a slot miller to create a groove in the axial direction on the workpiece, forming the tooth space. Next, B-axis rotation of the cutter enables it to machine the geometry of root and protuberance at the bottom of the tooth space. In subsequent steps, the gear wheel rotates in coordination with radial plunging of the cutter to turn-mill the upper and lower gear tooth profiles. Chamfers on the gear tooth’s OD can also be added. Developers say gear quality of DIN6 or AGMA11 can be achieved using involute milling, with a 2 µm Rz surface finish on gear flanks. Leaving stock for finish grinding after heat treating is an option when gears of higher quality and finer surface finish are required.

Of course, on a multitasking machine, other operations can be performed so that the gear, or a workpiece with gear-like features, can be finished in one setup. This is how InvoMilling can compete as a productive process when gears are not needed in high volumes. In addition, as a multipurpose machine, the multitasking CNC is available for non-gear applications.

The Programming Difference

Because the tool path determines the gear form, not the shape of the cutter, programming the InvoMilling process deserves attention. Sandvik Coromant worked closely with DMG/Mori Seiki to create a gear-milling module for the MORI-AP conversational programming system that runs on a PC for offline CNC programming. This software module guides the programmer through a series of entries pertaining to data about the desired gear shape, such as the number of teeth, pitch diameter, pressure angle and so on. All of this data is attainable from callouts on the part print, so a solid model in CAD is not required to calculate the tool path. InvoMilling algorithms in the software automatically create the process plan to machine a complete gear (sequence of steps as outlined above).

According to developers, the NT series turn-mills are especially suitable for involute gear milling because the B axis on these machines has ±120 degrees of rotation, a high-speed direct-drive motor and indexing that resolves to 0.0001 degree. Precise machine motions, however, must be supported by the high quality of the cutting tool. For this reason, the CoroMill disk cutters for InvoMilling are manufactured for very low runout and use coated carbide inserts with positive geometry on the cutting edges. The aggressive milling parameters appropriate for these cutters result in low cutting forces, enabling larger tooth forms to be machined even though the multitasking machining center is less massive than comparable hobbing machines.

New Directions

Although innovative processes such as InvoMilling promise to move gear making into broad new settings atracting fresh entrants to the field, these developments also reinforce some important shifts in general machining. Most notably, this is the ascendancy of the multitasking CNC machining center. Adding highly flexible and capable gear production further solidifies the value of single-setup, integrated machining.

Likewise, these developments demonstrate the benefits of close cooperation between machine tool builders, manufacturers and software developers. Such joint efforts reduce development time and bring innovations to end users more quickly. There will be fewer delays waiting for the capability of the machine, the cutting tool or software to catch up with advances in the other sectors.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)