Conformal Cooling: A Tool in the Toolbox to Build a Better Mold

Moldmakers are just starting to scratch the surface of what can be done with conformal cooling, which involves an additive approach.

Six years ago, when Linear Mold & Engineering (Livonia, Michigan)—a manufacturer of plastic injection molds, blow molds, foam tooling and prototype parts for the automotive, aerospace, medical and military industries—decided to invest in additive fabrication services to open up new doors of opportunity, President and CEO John Tenbusch did not realize that this investment would take the company even further.

Today, not only has Linear become one of only a handful of service providers in North America for metal prototype parts—using direct metal laser sintering (DMLS) from EOS of North America (Novi, Michigan)—it also uses this additive technology to grow tooling inserts with cooling lines already designed inside, achieving maximum part quality and lower costs. Most of Linear’s conformal cooling work is coming from existing automotive and medical customers, and packaging applications.

Linear now has three EOSINT M 270 machines and is looking at a fourth—currently the enhanced EOSINT M 280 machine designed with four extra inches in the Z axis (now at 12.8 inches), primarily extended for toolmakers. Available materials for DMLS include maraging steel (MS1), 17-4 and 15-5 stainless steels, cobalt chrome, titanium (Ti64), Inconel (IN625 and IN718), and aluminum (AlSi10Mg).

Winding Water Lines

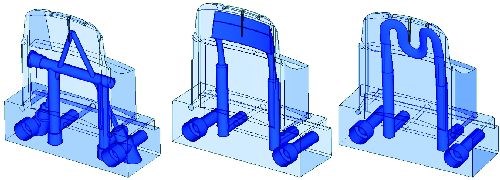

“The use of conformal cooling is an opportunity for companies looking to add to the bottom line by improving cycle times and quality,” Tenbusch says. “Manufacturers of high-volume molding operations should consider looking at this technology because there have been very few changes in the last 25 to 30 years in mold construction when it comes to the cooling of molds. Today, water lines are drilled at straight lines intersecting each other, and plugs and baffles are added to direct the flow of coolant—just like 20 years ago, only with faster equipment. This helps the mold to be built faster and more efficiently, but does nothing to address the same issues of molds that run too hot, thus slowing cycle times. DMLS technology allows for the cooling channels to be added to the inserts without having to consider the limitations presented with conventional machining, thus maximizing the surface of the cooling channels and eliminating mold hot or cold spots.”

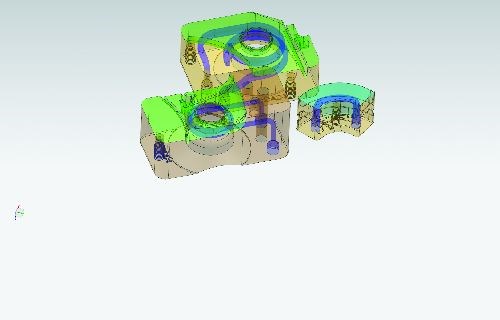

According to Linear, the concept behind conformal cooling is that all heating/cooling lines in the tool follow the contour of the part, maintaining an optimal distance from the part surface in order to maintain a constant temperature. This is especially useful in areas on a part that may need to be thicker or have a tall core feature with an odd shape. Studies have shown that using conformal cooling methods can significantly reduce cycle times—between 15 and 45 percent, depending on part complexity. Not only does this reduce the time needed to run the part, it also can help improve part quality.

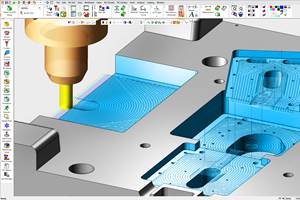

For prototype tooling, the inserts can be grown through DMLS in parallel to the rest of the mold being cut on the CNC machines. Grown inserts can be used for clip ribs, attachment features or any required tooling actions out of the line of draw. This can eliminate the need for EDM, reduce costs and shorten leadtimes. The grown inserts are post-processed, benched and then spotted into CNC-cut pockets on the core or cavity of a tool in a fraction of the time of a conventionally created detail without having to tie up a CNC machine or EDM tank. According to Linear, DMLS inserts are accurate enough for most prototype tooling without any CNC finishing or machining.

Using DMLS to grow tooling inserts allows Linear to install conformal cooling lines throughout a tool, even in the tightest areas. This method of cooling provides Linear and its customers with better-quality plastic parts in shorter cycle times, thus lowering operating costs.

“Conformal cooling does not apply everywhere, but there are so many applications where it does apply, and people are just starting now to really latch onto it,” Tenbusch says.

Two of the strongest reasons to learn and apply conformal cooling are cycle time and quality improvements. “You are able to mold thin walls, etc., because you can control the temperature so much better than in the traditional mold,” Tenbusch explains. “You can control diameters very well,

and flatness or straightness on a thin wall. There are all types of advantages. I think we are just starting to uncover what we can do with conformal cooling.”

In terms of mold/part design limitations, Tenbusch says they are not an issue. “With conformal cooling, you can pretty much grow anything,” he says. “You can be very creative in your design because you are not dealing with traditional machining processes.”

The only true limitation is size, he says. “You are working with roughly a 10-inch cube, so mostly you’re going to want to work with smaller parts or add inserts into tools with larger parts that have tool hot spots, which are slowing down cycle times.”

“Cool” Applications

A recent application for Linear is a tube with a very thin rib, and because of the shape of the rib and the fact that it wraps around the entire round insert, the customer cannot EDM-burn this feature into the core. The entire insert has stock added for machining purposes, except for where small fingers are needed. These features are grown net and then finish-polished. Linear is growing the core with a conformal cooling line on the inside and also growing the feature—very thin plastic that will bend and slide off and go back in position—as part of the insert. According to Tenbusch, design is wide open.

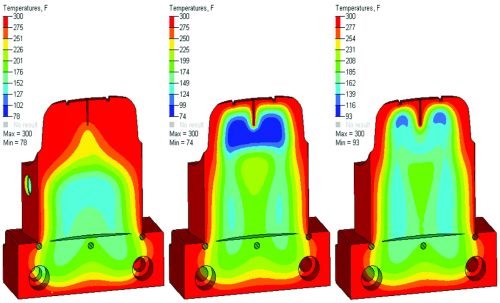

A good application for conformal cooling inserts via DMLS is engine manifold covers, where one ends up with a large, thick section of glass-filled nylon that stays very hot for a long time, Tenbusch says. But he believes that the best application moving forward is going to be in the packaging world, where manufacturers are making 1 million-plus pieces per week and only looking for two or three seconds of cycle-time improvement. To those companies, this approach is a big deal. Linear has a couple of customers in the packaging world who are enthusiastic about the technology and are creating some prototypes, he maintains. Linear has completed some finite element analyses (FEA) for them, showing the cooling efficiency gained by creating the conformal cooling lines inside of the insert and proving these efficiency gains via FEA simulations when compared to the traditional straight-line drilling.

Another project Linear is currently working on involves a German customer that knows conformal cooling works and is determined to add it to its North American operations. The German company chose Linear to get the tool built and approved the company’s decision to work with a partner to build the production tool.

Canadian tool shop Aalbers Tool & Mold (Old Castle, Ontario)—a production tool builder for the

automotive industry—is building the production tool while Linear supplies the finished inserts. “We’ve been working with Aalbers for five or six years,” Tenbusch says. “They don’t really build prototype tools, so when their customers request prototype tools they come to us, and we’ve gone to them for production tools when it is something outside of what Linear can handle.”

Linear is doing the finishing of the inserts. The company purchased a Makino F5 VMC about six months ago because these conformal inserts need to be hard-milled when they are finished. “In most instances we add stock and then machine it away to provide a finished insert,” Tenbusch explains. “They supplied us with mold flows and real-world data they had from existing production tools to show where the hot spots are, so we can go back and put inserts with the conformal cooling to address where those hot spots are.”

Right now Linear is wrapping up the design phase. “It’s a pretty hairy tool,” Tenbusch says. “A lot of action. We have to get creative on where we can put the water lines to get to the inserts. Ejector pins are in the way and mechanisms are coming in from the side and bottom. Engineers are putting inserts around the manifold drops and irregular-shaped towers that have ribs, and adding some thick wall sections where they meet the nominal wall stock. Since these parts are functional parts that are part of the vehicle HVAC system, appearance is not an issue; the goal is to improve cycle time. We are all really confident that conformal cooling will help.”

Moving Forward

As pressures from OEMs continue to mount on Tier suppliers for cycle time and quality improvement, mold manufacturers will be forced to take a serious look at adopting additive technology for conformal cooling into their current mold building operations.

According to Tenbusch, if a moldmaker wants to get involved, it needs to have a customer base that would be looking for such a benefit, because there is a cost increase. “The moldmaker would need to have customers who are driving toward this approach,” he says. “Someone pushing for conformal cooling—that seems to be how this technology is being adopted.”

Instead of losing a customer who wants to employ conformal cooling, a moldmaker new to this technology and not ready to make the investment in the machine can outsource the work to a service bureau such as Linear that has the necessary experience.

Tenbusch summarizes, “In order to be able to feed this additive technology monster that is growing like crazy, as well as our mold building operations and manufacturing—all of which require large amounts of capital investment—we’ve found we really need to have our act together. But one of the extra benefits is that additive technology has turned out to be a wonderful marketing tool for our company as well. As more companies show interest in this technology, being one of the few shops capable of making these mold inserts, using multiple laser sintering machines, should help to keep us on the forefront of moldmaking technology.”

Related Content

YCM Alliance Hits IMTS

YCM Technology has joined with other like-minded machine tool manufacturers to take a solutions-based approach to manufacturing.

Read MoreHexagon Acquires TST Tooling Software Technology

Hexagon acquires TST Tooling Software Technology, a distributor of VISI, Hexagon’s CAD/CAM software for the mold and die sector, and PEPS CAM software.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreCimatron's Updated CAD/CAM Software Streamlines Mold Design

Eastec 2023: Cimatron V16 includes a clean new user interface and increased automation for faster mold design, electrode creation and NC programming.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)