Conveyors Provide Flexibility, Energy Savings

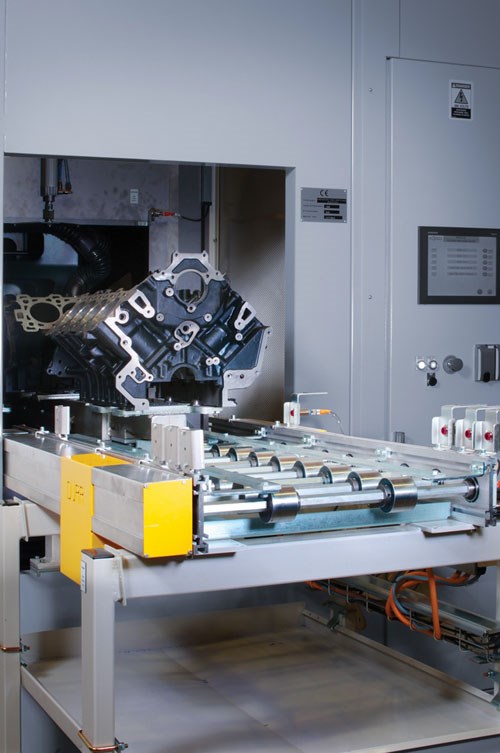

Low costs and quick installation were key factors for automotive manufacturer Nemak when the company sought a new conveyor system to accommodate expanded production of a line of cylinder heads. In addition to meeting these needs, Dürr Ecoclean’s PZR conveyors provided energy savings, easy maintenance and improved safety.

Flexibility, fast delivery time and low cost are among the factors many manufacturers use to evaluate potential new suppliers. Automotive manufacturer Nemak, a division of ALFA, needed all three when it recently sought to obtain a conveyor system for expanded production of one product line at its Saltillo, Mexico facility. In addition to quickly delivering an inexpensive, modular system that is easy to maintain and reconfigure, Dürr Ecoclean (Wixom, Michigan) was flexible enough to cater to Nemak’s preference for contracting with local sources and suppliers where it could.

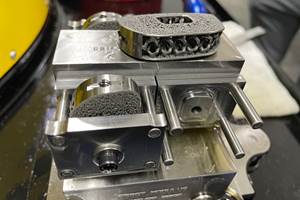

Established in 1981, Nemak specializes in the production of aluminum cylinder heads. Since its founding, Nemak has grown significantly. It currently operates 29 plants in 13 different countries in the Americas, Europe and Asia. The Saltillo location began operation 1999 and is dedicated to the casting of engine blocks and cylinder heads for internal combustion engines. With approximately 1,000 employees working in three shifts, the facility has capacity to produce 2 million parts per year for several global engine programs. Its products are exported to the United States, Canada, Europe, Australia and Asia.

When Nemak decided to purchase a conveyor line to accommodate additional production of one if its aluminum cylinder heads, the company initially had a turnkey system in mind. However, management soon realized that it needed to be more involved in the planning and layout than would be possible with a full turnkey system. Additionally, the company felt that moving away from turnkey would enable it to keep costs low by contracting with local suppliers for the conveyors’ electrical controls. Quick delivery soon became another central concern—time was already short when the company changed its acquisition philosophy.

To facilitate the need for speedy deployment, Dürr Ecoclean, a subsidiary of Dürr AG, proposed its Powered Zone Roller (PZR) floor conveyors. While the company can also supply turnkey systems, these conveyors are predesigned and preassembled. This allows Dürr to simply pull the conveyors from stock and ship them relatively quickly, as opposed to building a system from scratch after the layout is planned. Nemak was attracted by the supplier’s ability to provide an off-the-shelf solution rather than going with an "all-or-nothing" approach, as well as the concept of a catalog-standard system designed to be easy to deploy, integrate and maintain.

PZR conveyors feature a modular design to simplify layout planning and system integration. According to Dürr, this makes the system especially useful for future line reconfigurations or expansions because the modules can be rearranged like building blocks. The ability to adjust the spacing between rollers to suit different part types further increases the system’s flexibility, the company says.

Another notable selling point for Nemak was the fact that the conveyors are designed to allow parts to accumulate without touching one another. The modules are arranged in a series of "zones," each driven by its own bi-directional motor. Unlike traditional engine production conveyors that run continuously, these zones operate only when a part enters or exits. This is accomplished via sets of photocells in each zone that detect when parts enter or leave and then start or stop each individual motor accordingly. And because parts ride directly on the conveyor’s rollers, which are available in plastic or steel, no pallets are necessary.

This configuration not only reduces power consumption, which provides increased energy efficiency and lower costs, but also results in less wear and tear and lower environmental noise. Safety is improved as well, as the PZR’s design is said to eliminate the numerous pinch points and finger traps commonly found in part-to-part accumulating systems. According to Dürr, the nature of the pre-engineered system also makes it easier and more expedient for users to obtain spare parts when needed.

Using proprietary software that allows standard PZR modules to be dragged and snapped together on a virtual plant floor, Dürr Ecoclean consultants worked with Nemak to determine the scope of supply for the purchase. In addition to the conveyor modules themselves, the company purchased other Dürr Ecoclean technologies, including an EcoCTrans transfer-style washer with a cooling tunnel and an HR Black Washer Filter.

The company now has 100 modules of PZR in a stand-alone conveyor line used for additional production of aluminum cylinder heads. Manual hoists are used to transfer the parts to and from the conveyor line and the company’s HMCs. After proceeding through the EcoCTrans washer, parts index atop the PZR to inline gage and leak-test operations. Three operations—part marking, water jacket plug insertion and inspection—are performed directly on the conveyor line before parts proceed to the manual pack-out area.

The system was installed, wired, debugged and commissioned at the facility in 2 weeks. By investing in a product that was easy to install, available quickly off-the-shelf and allowed it to contract locally for controls and installation support, Nemak was able to meet a tight schedule for expanded cylinder head production.

Related Content

Moving To Magnets Doubles Productivity

Moving from hydraulic to magnetic fixtures enabled this shop to reduce setup time, improve rigidity and eliminate manual operations. As a result, productivity doubled.

Read MoreMedical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

Read MoreAn Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

Read MoreShop Doubles Sales with High-Mix, Low-Volume Automation

Robots with adaptive grippers have opened entire shifts of capacity to high-mix, low-volume shop Précinov, doubling its sales.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More