Coolant-Cleaning Device Slashes Downtime

Founded in 1975, Stanfordville Machine supplies precision parts to the semiconductor, medical, aerospace and electronics industries. Running a busy shop with 24 machines, Stanfordville management continuously invests in new machines to stay abreast of the latest available technology and ensure just-in-time deli

Founded in 1975, Stanfordville Machine supplies precision parts to the semiconductor, medical, aerospace and electronics industries. Running a busy shop with 24 machines, Stanfordville management continuously invests in new machines to stay abreast of the latest available technology and ensure just-in-time deliveries. However, Peter Johnsen, manufacturing manager, found that lack of effective maintenance of the coolant in machine sumps compromised objectives for long-term investments in tools and tooling. Buildup of tramp oil and other impurities in the coolant required frequent pump-outs of the sumps, resulting in excessive coolant and waste disposal costs as well as unscheduled machine downtime.

The Stanfordville, New York-based company pursued some typical approaches for keeping the coolant clean. It tried a skimmer with no success. The skimmer operated only in a small area of the sump, leaving most of the sump covered with oil, and it removed a large quantity of coolant along with the tramp oil. Next, the company tried a pumping separator with an electric pump. The electric pump immediately proved to be unreliable, and the overall construction of the separator was not rugged enough for the company’s application.

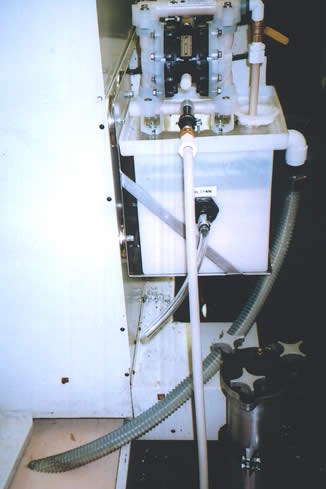

Mr. Johnsen eventually contacted Keller Products, a manufacturer of pump/separators that are specifically designed for trouble-free service. Available in both dedicated and portable configurations, each includes a 0.5-inch, air-operated diaphragm pump and a permanent oil-separating (coalescing) element that requires virtually no maintenance. Mr. Johnsen did not want to require his crew to move portable units, so Keller recommended its TKO line of pump/separators to service individual sumps.

The TKO skimmer pumps oily coolant from a floating inlet device on the surface of the sump. The coolant then moves through a pre-filter that removes floating chips before flowing into a separator tank that contains the manufacturer’s custom, permanent separator element. The separated tramp oil is held in the tank until it can be drained, while the cleaned coolant recycles continuously to the sump at high flow rate. The high recirculation rate rapidly turns over the sump, ensuring that there are no stagnant areas in which oil and solids can accumulate.

Mr. Johnsen ordered two of the smallest unit in the TKO line, the TKO-6, which can be mounted to the side of a machine tool without hardware using a magnetic frame. This feature was especially important for Standfordville because it keeps the aisles clear for stock movement.

The company machines primarily aluminum, which generates a large quantity of floating fines that are pulled into the separator along with the tramp oil. Although the separators are equipped with a standard cartridge-type pre-filter, Mr. Johnsen requested that Keller supply the units with a high capacity bag filter for added operating convenience.

After a month-long trial, Mr. Johnsen ordered identical units for his remaining machines. “I have cut my waste generation from ten drums per month to two drums per month,” he says. “In addition, I have increased production by minimizing downtime, which helps us meet our customer deadlines. By removing the tramp oil, my coolant is less likely to foam, and filtering out the aluminum means I am less likely to plug coolant lines in my machines. The Keller units paid for themselves in a few months.”

Related Content

STLE Opens Registration for 2024 Annual Meeting

The Society of Tribologists and Lubrication Engineers’ 2024 STLE Annual Meeting & Exhibition will take place May 19-23 at the Minneapolis Convention Center in Minneapolis, Minnesota.

Read MoreManaging Coolant with Skimmers, Refractometers and More

Bacteria-infected coolant harms machines and sickens machinists. Coolant management technologies like skimmers and automated systems counter this tendency.

Read MoreUnist's Electronic Control Regulates Lubricant Delivery

Unist’s Pulse R electronic control ties into the system control solenoid valve and takes the place of a pneumatic pulse generator timer or logic block.

Read MoreHennig Inc. Acquires Industrial Coolant Systems

ICS develops and field tests high-pressure coolant systems, coolant filtration systems and other machine tool solutions.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More