Curve Interpolation For Less

When the CNC executes the program faster, a higher feed rate becomes possible. Precisely this benefit has compelled many mold makers in particular to inquire about NURBS.

Many shops are familiar with the premise of NURBS interpolation. A tool path that might otherwise be defined as a series of short, straight lines is defined instead using mathematically defined curves (non-uniform rational B-splines, to be exact). The resulting decrease in the number of program blocks can reduce the amount of data needed to describe the path. When this lets the CNC execute the program faster, a higher feed rate becomes possible. Precisely this benefit has compelled many mold makers in particular to inquire about NURBS.

Some have inquired to Kathleen Holst, an applications engineer with Fadal Machining Centers.

Ms. Holst has told many of these shops that NURBS is more than they need.

Fadal machines capable of NURBS achieve that capability using a Siemens CNC. Fadal has offered Siemens control as an option on its machines for the past 3 years. This CNC line makes NURBS available as an extra feature. However, a standard Siemens feature can deliver comparable benefits for the typical mold shop user, Ms. Holst says. The feature is called “CIP” interpolation, for Circle Intermediate Point.

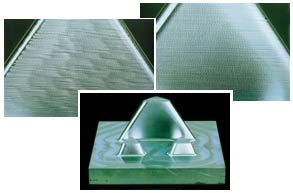

CIP interpolation is curve interpolation of a more restricted form. The capability applies only to circular arcs. It’s similar to the circular interpolation functionality available on basic controls for decades, but an important difference is that CIP isn’t limited to circular arcs in a two-axis plane. CIP interpolation follows three-axis arcs. This accounts for why it can work so well as a NURBS alternative, Ms. Holst says.

Using NURBS comes at a cost. Shops implementing the capability need that feature of the CNC, as well as CAM software capable of outputting NURBS tool paths. To use CIP interpolation there is still a cost, but it’s not as much. The requirement is a software translator able to convert standard, straight-line CAM output into NC code that includes CIP commands. Ms. Holst cites two companies offering such software: Cimco Integration (Maynard, Massachusetts) and Northwood Designs (Antwerp, New York).

The translator searches the straight-line NC code for opportunities to replace any series of straight lines with a circular arc. Complex curves made up of a large number of straight lines can thus be defined more compactly using a smaller number of arc moves. The impact on file size can be dramatic. A 30 MB program could be condensed to less than 1 MB.

And this file size is still an important concern. Though proessors have become more powerful and memory more affordable, mold makers’ demands have kept pace with the improvements. The drive to reduce or eliminate hand polishing has led shops to generate programs with ever-tighter chordal tolerance and step-overs measured in ten-thousandths of an inch. Many shops still push against the performance limits of their CNCs.

This is particularly true where shops use less-expensive controls. Ms. Holst compares the Siemens model 810 control to the more sophisticated (and more expensive) model 840. Taking advantage of CIP interpolation can narrow the performance gap between these two CNCs, she says. One 10,000-line program might nearly fill the memory on the lower-end control, but formatting the program in CIP lets a dozen or more programs occupy the same space. And while the control’s attempt to execute the large program might result in a slow feed rate or a coarse surface, executing the CIP version of the same program can—in the right applications—deliver the fast feed and smooth surface the shop might otherwise expect from the higher end control running NURBS.

Related Content

When to Use Custom Macros With a CAM System

Custom macros can offer benefits even when using a CAM system to prepare programs – but must be implemented with the right considerations.

Read MoreFrom Tradition to Transformation: Century-Old Manual Machine Shop Adds CNCs

After 122 years of working with manual mills and lathes, this fifth-generation shop acquired assets of a local CNC machining business and hired the owner. Here’s how it’s going a year later.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read MoreUnderstanding CNC Machine Accuracy and Repeatability

Properly evaluating machine tool capability requires understanding how the both user and the builder can influence precision.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)