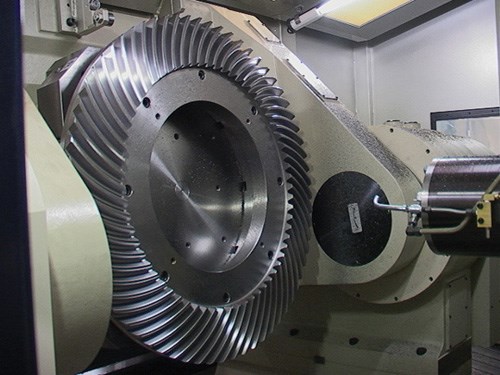

Cutting Spiral Bevel Gears On A Five-Axis Machining Center

To produce high-precision ring gears in low- to mid-volumes, an emerging option is the use of five-axis machining centers. Mitsui Seiki CNC vertical and horizontal machining centers are being used in this application.

Manual gear hobbers or specialized CNC gear cutting machines are generally the fastest and most efficient means for producing high-precision ring gears, especially in high volumes. For low- to mid-volumes, another emerging option is the use of five-axis machining centers. Mitsui Seiki USA, Inc. (Franklin Lakes, New Jersey) says several of its customers are cutting 10 to 14 class ring gears for aerospace and power generation on its CNC vertical and horizontal machining centers. Apparently, part volume for these applications is not high enough to justify dedicated gear-making machines, yet demand for precision and complex geometry calls for five-axis capability.

For example, the company’s Vertex VMC can be used for spiral bevel gears as large as 16 inches in diameter. A special version of this model incorporates a rotary trunnion table for finish turning operations. With this configuration, as many as three turning operations can be performed, along with milling of the teeth and flat surfaces. This happens in one setup prior to heat treating.

An important enabling technology to successful gear cutting on this class of five-axis machines is software developed specifically for this application. Mitsui Seiki partnered with CNC Software, Inc. (Tolland, Connecticut), the producer of Mastercam CNC programming software, to create programming routines that generate tool paths for the complex geometry found in spiral bevel gears.

A five-axis HMC can also be used for spiral bevel gears. The company reports that an HU80A-5X horizontal machining center, one of its largest five-axis models, is producing these gears in diameters as large as 35 inches. "One of the benefits of producing gears on that machine is that the relative gearboxes or gear cases, and even reduction gear boxes, can also be processed on this one machine," says Mark Speier, a sales engineer at Mitsui Seiki. "The gear housing is a critically precise piece. The accuracy of both parts has a direct correlation to the transmission performance over the life of the motor." According Mr. Speier, the gear is mounted flat and then turned 90 degrees (or other appropriate angle) so that an end mill can cut at the best attitude to the gear profile while roughing. For finishing, ballnose end mills generate the final profile before heat treating. The company is working to equip this machine for turning operations so that users can attain single-setup efficiency.

The company makes the point that the overall cost of producing gears in low volumes on a five-axis machine is likely to compare well with traditional gear cutting machines when tooling economies, reduced part handling, the inherent accuracy of single-setup machining and improved process control are taken into account.

Related Content

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

-

Best Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)