December 2009 Machine Tool Sales

On December 8th, the USMTC released its monthly report on machine tool orders. The report showed that December was by far the best month for machine tool sales in 2009. Both December unit and dollar sales were at their highest level in 2009.

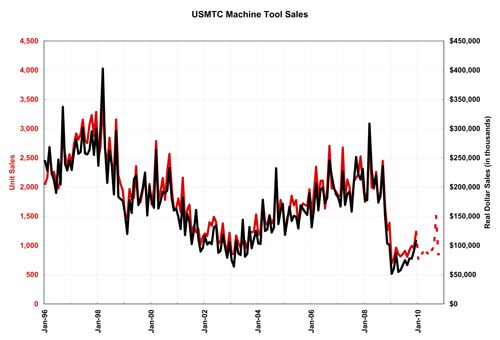

On December 8th, the USMTC released its monthly report on machine tool orders. The report showed that December was by far the best month for machine tool sales in 2009. Both December unit and dollar sales were at their highest level in 2009. Also, December showed the best relative performance to the prior year of any month in 2009. Although December 2009’s unit sales were still down 11.1% compared to December 2008, real dollar sales in December 2009 were 6.8% higher than they were in December 2008. The chart USMTC Machine Tool Sales shows unit sales and dollar sales (I show real dollar sales here while USMTC reports nominal dollar sales) as reported by USMTC. The dotted red line represents my forecast for machine tool unit sales for 2010. Keep in mind that the USMTC report doesn’t capture the entire market and that participation in the survey has increased in over time.

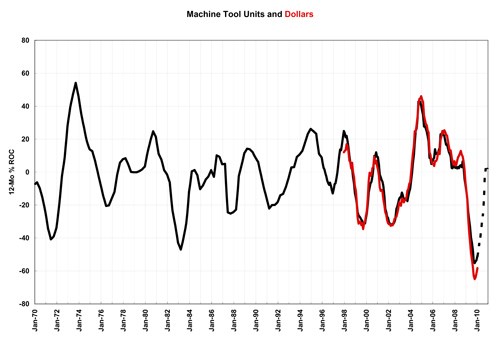

The chart Machine Tool Units and Dollars shows the 12-month rate of change for machine tool units and dollars (again, the dotted line is my forecast). I have supplemented the USMTC data with historical data from the MQ35W report created by the federal government. Here we see that both units and dollars have bottomed. The dollar curve bottomed lower than the unit curve, indicating a significant oversupply of machine tools and a lack of pricing power for suppliers. I expect this situation to correct itself during 2010. We’ll know that has happened when the two curves are once again tracking each other almost exactly. This chart shows that machine tool sales are still contracting but that they are doing so more slowly.

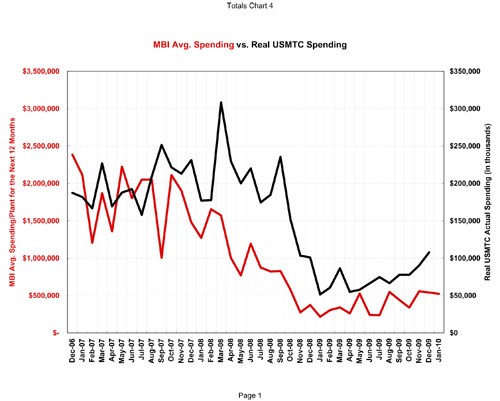

To forecast machine tool sales I look at two leading indicators. The first is an average spending per plant for the next 12 months that we compute from our Metalworking Business Index (MBI). The chart MBI Avg. Spending vs. Real USMTC Spending shows that future spending plans bottomed in January 2009. Since that time future spending plans have increased slowly. Real spending on machine tools according to USMTC lags the spending expectations from the MBI.

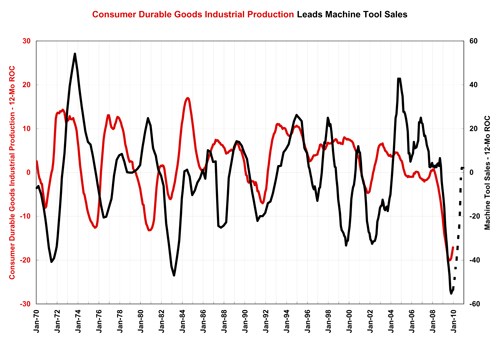

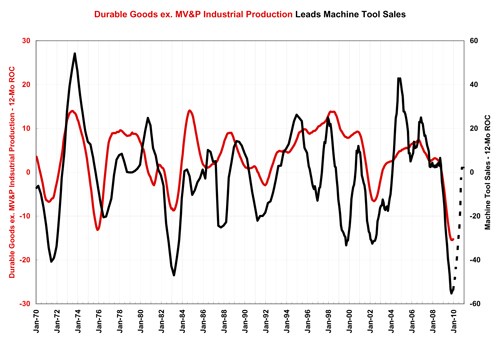

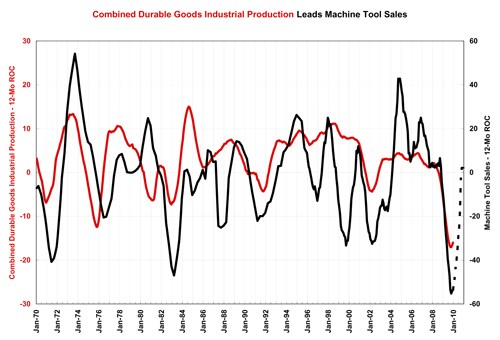

The second leading indicator is industrial production. There are three industrial production indexes that I correlate to machine tool sales using 12-month rate of change curves – consumer durable goods, durable goods excluding motor vehicle and parts (what I call business durable goods), and combined durable goods. The first two are actual indexes computed by the Federal Reserve. The third is a weighted average (40% consumer durable goods and 60% business durable goods) of the first two. The combined industrial production curve is the best leading indicator for machine tool sales. On average, machine tool sales lag industrial production by 12 to 18 months. The lag time is typically shorter for contractionary periods. The last three charts show that industrial production bottomed between August and November 2009, depending on which curve you use. The rate of change curve for machine tool units bottomed in October 2009. I expect machine tool sales to contract more slowly for most of 2010 with machine tool sales in 2010 ending up slightly higher (about 2%) than in 2009.

Read Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)