The NASDAQ stock exchange is typically associated with the likes of Apple and Google, but at least one company focused on manufacturing has been part of this exchange from the beginning. WSI Industries, an 80-employee contract manufacturer in Monticello, Minnesota, is one of only about 300 companies that have been continuously listed here since the start of the exchange in 1971. This detail is somewhat fitting, because WSI thrives by staking out territory where most other machining contractors don’t venture.

The company pursues ongoing production programs involving large parts or large quantities. To be sure, many shops pursue these programs because the work offers obvious benefits. Unlike a prototype run or similar short-term job, the long-run program gives the shop a chance to refine a production process around the part, and to recoup its investment in doing so. But company President Benjamin Rashleger says the very reason WSI wins and retains such programs is found in that one word: “investment.” The cost and scale involved in meeting the demands of committed or even semi-committed programs constitute the principle challenges of this work.

For example, the traits that enable WSI to win ongoing jobs from major OEMs include extensive in-house engineering support, project management staffing, the production capacity to quickly run parts as needed, and the capital to both carry customer inventory and add new equipment in response to new demand. All these elements add to overhead, and the overall expense of that overhead requires WSI to keep courting and surpassing the expectations of companies that can provide high-value orders. Mr. Rashleger freely admits that, given this overhead cost, WSI can’t economically compete for the non-recurring work that comprises most contract manufacturing. When an established customer sends WSI an order for a part number that won’t repeat, the company often seeks the customer’s permission to outsource that job to save cost.

During a recent walk around the company’s production floor, Mr. Rashleger detailed some of the realities of large-program production. Just one of those realities, he says, is that machining is taken for granted.

Beyond Metalcutting

WSI currently divides its work into three businesses. One is high-volume machining of aluminum, which mostly consists of parts related to light-vehicle engines in quantities of thousands of pieces per month. The second business is repetitive batch work. This consists of part numbers that keep coming back but are machined in quantities of perhaps only 200 per month. The third business is the most recent addition and the fastest growing: producing large parts, mostly in steel, for customers in the energy sector.

Repetitive batch work is the only area in which machining capability alone wins jobs. This business is segregated into a section of the production floor that includes a well-organized library of fixture tooling for the many recurring jobs. This business runs smoothly and is largely self-

contained, Mr. Rashleger says, but it accounts for only about 20 percent of total sales.

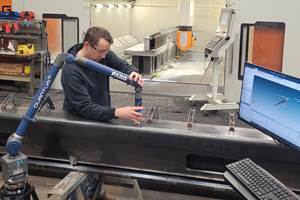

To serve the other two businesses, WSI typically has to go well beyond cutting metal, because the customer is often more interested in the shop’s ability to validate the part or perform additional processing. For example, a line for aluminum cylinder heads includes a custom-engineered test fixture along with a parts washer and a pressure tester. Pointing to the horizontal machining center at the beginning of this line, Mr. Rashleger says, “The customer doesn’t even ask about that. Machining is the part of the process that everyone assumes you can do.”

Committed Resources

Work for an oilfield-related customer got WSI into turn-mill machining for the first time. In addition to purchasing new equipment, the company dedicated two project managers and one engineer to this customer—all despite the fact that the work itself is not reliable.

Energy is “a hard business,” Mr. Rashleger explains, one involving dramatic swings that can “shut the work off immediately.” Even so, this new machine tool—an Okuma turn-mill with a turning diameter of 710 mm—was essential to run the customer’s parts efficiently. WSI therefore bought the machine on just a handshake agreement with the customer. In essence, this agreement said that if WSI kept delivering the work as required, the shop would keep getting the work so long as the customer has the work to give.

WSI is trying to diversify within the energy sector, pursuing work related not only to oil, but also to natural gas. Another recent machine purchase is a 50-taper Milltronics HMC (Mr. Rashleger is the former president of Milltronics) that is large enough to accommodate massive steel manifold components used for hydraulic fracturing operations in natural gas extraction.

Personal Contact

One might think the choice of manufacturer for a large and costly production program would be based on a scrupulous analysis of cost and value. It is, says Mr. Rashleger says, but intangible factors figure in as well. Large-scale production is actually an emotional buy—or at least as much of one as an industrial purchase can be.

He says WSI “shows well,” and this is an important asset. The production floor is kept clean and organized, with the equipment well-maintained and (if possible) busy. The manufacturing area itself is one of the company’s best resources for selling manufacturing.

Yet ultimately the staffing is the most important factor influencing the customer’s level of comfort. Program managers at WSI perform the vital role of giving each customer a personal advocate within the company for managing special needs. By calling on the program manager’s help, for example, a customer can get a one-piece emergency order squeezed into machine schedules and sped through production. With enough program managers to provide personal attention to customers, WSI is staffed large enough to appear “small” when it comes to responding to special demands.

The company recently performed a marketing survey eliciting feedback from customers. One finding revealed the importance of a simple practice at WSI: the habit of phoning customers every time there is a problem or delay with a job. Various customers expressed how valuable they thought this was. The practice reassures customers that they don’t have to frequently check in, because they know the company will communicate any concerns before it occurs to them to worry.

Capacity is a Tough Call

Mr. Rashleger says one of the hardest decisions he routinely faces is when to buy a machine tool. Having too much capacity obviously adds to the company’s burden when business is down. Yet having too little capacity is potentially even more expensive, because it might prevent the shop from taking on new work with short notice—and just about all new work comes with short notice.

“With one phone call, our business can pick up dramatically,” he says. Immediately after such a phone call comes in, he often has to make several calls himself to find equipment required for the new job. In fact, when he gets even a hint that additional business might be coming, he alerts machine tool dealers, which sometimes keep machines waiting and earmarked for him. The dealers are willing to do this because WSI routinely pays premiums for machine tools that are in stock and ready for immediate delivery.

The ideal situation, he says, is always to have just one relatively large and capable machine tool open and waiting. When this is the case—when all the machines in the shop are busy except this one—the shop can still take on new work immediately. That is, the shop can start using the machine it has available, while Mr. Rashleger sets about obtaining equipment that is better-suited for the job.

Overseas Is Not Far Away

Even when the shop does everything right, it still loses jobs. For one part number, the shop had achieved a defect rate of less than 500 pieces per million and an on-time delivery rate of more than 99.6 percent—two outstanding figures given the complexity of the product. Nevertheless, a shift in relative currency prices sent the work overseas. In some cases, in fact, customers have told WSI that it is their new policy to seek manufacturing in low-cost countries for certain parts. In response to such developments, WSI has formed its own relationships with low-cost country suppliers in which WSI still provides supplier management, logistics and quality assurance. Because of these arrangements, the company now has about $1 million of work-in-process inventory from overseas at any given time.

For practically every part that WSI manages in this way, not all of the machining goes overseas. There are some operations the distant shops can’t do. On the cylinder heads, for example, WSI machines the fine-precision features requiring control against the thermal expansion. But the expertise gap is a moving target, Mr. Rashleger says. The capabilities of overseas suppliers are steadily improving. To stay ahead, WSI has to keep moving as well—continually finding ways to meet tighter engineering demands and even more challenging customer requirements.

.jpg;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)