EDM, Metrology System Pairing Opens New Doors

Seeking a solution for producing and measuring smaller, more intricate parts, this shop combined a ram EDM unit and optical 3D metrology system. Each provided significant benefits on its own, but the pairing of the two technologies enabled the company to achieve new levels of precision and productivity.

As applications shrink in size and increase in complexity, manufacturers of precision molds must meet ever-tighter tolerances and more stringent surface finish requirements. As if that weren’t daunting enough, this more difficult work places equally demanding requirements for precision on the inspection process as well. However, with the right combination of technology, sufficiently dedicated shops can not only meet these challenges, but also expand their micromachining capabilities and gain a competitive edge.

EDM Department, a Bartlett, Illinois-based contract manufacturer, is a case in point. Uniting a high-precision EDAC1 ram EDM from Makino (Mason, Ohio) with the Infinite Focus optical, 3D metrology system from Alicona Imaging (also based in Bartlett) has enabled the company to reach levels of accuracy and repeatability that outclass anything it had previously achieved. As a result, the company has saved both time and money while bringing in new work. “We have a bright future ahead of us with a whole new list of clientele that didn’t exist before, and we have these two technologies to thank for that,” says Mark Raleigh, company CEO.

EDM Department provides flexible manufacturing services to a range of industries, including aerospace, defense, medical and telecommunications. Mr. Raleigh founded the company with a vision that it would invest equally in its technology, resources and customers. “We operate under the premise of three business models in one,” he explains. “We have a research and development facility, a production facility, and a turnkey solutions facility. With this approach, each division benefits from the other, providing the availability of equal energy and resources for our customers and ensuring a competitive stance in the global market.”

Maintaining that competitive edge, however, has become more difficult in recent years amid an increase in smaller, more challenging work and numerous design reviews, Mr. Raleigh says. He notes that when the company first considered adding to its machining capabilities, it was already producing features and elements at the 100-micron level. Today, 25-micron features are common. Some work even requires 10 microns.

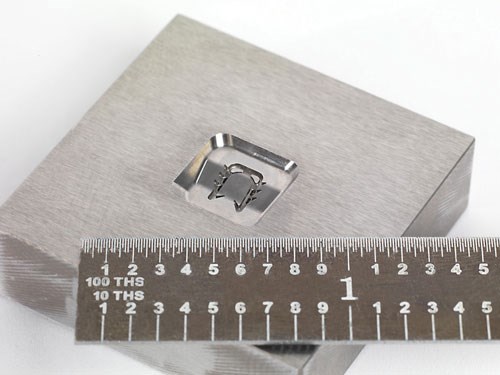

The company needed a robust solution that would enable it to measure tolerances on a 1-micron scale, and Makino’s EDAC1 ram EDM did not disappoint. Running the machine through a gauntlet of positioning, surface finish and general machining tests revealed that it was actually more capable than anyone had anticipated, Mr. Raleigh says. The machine is capable of producing corner radii measuring 0.00019 inch (0.005 mm) and surface finish quality of 0.000024 inch (0.6 micron) Ry, and it provides submicron repeatability. It also achieves positional and pitch accuracies of ±0.00004 inch (1 micron). Thermal barriers and a Z-axis stabilizer enable cooling the Z axis and decreasing thermal growth, the manufacturer says. Additionally, the machine’s C axis and Mi head provide precise electrode positioning accuracy at multiple angles.

Mr. Raleigh says the primary benefits of the EDAC1 are its accuracy and stability, which have enabled tighter tolerances and improved process capabilities. “To quantify accuracy and stability, we have to include the effect that the environment creates, so we continually reference our machine position over time,” he explains. “The average daily true positional drift with the EDAC1 is less than 2 microns, and less than 3 microns during a 27-day period for the XY plane. The Z axis drifts less than 1 micron daily and considerably less than 2 microns during a 27-day period.”

The machine’s repeatability has also contributed to cost savings and the company’s competitive edge by improving productivity and reproducibility, Mr. Raleigh notes. In fact, EDM Department’s return on investment since the purchase has exceeded the company’s expectations by approximately 50 percent. “It has taken us to the next level of micromachining, and it is fully capable of what we’re trying to achieve,” he says.

While the new machine provided the means to produce smaller, more intricate parts, the company still needed the ability to see and measure those parts. It found that solution in the Infinite Focus, an optical 3D metrology system designed to generate high-resolution, repeatable and traceable results. “It affords us the chance to look at what we are making and measure the surface finishes in high detail,” Mr. Raleigh notes. “When other methodologies are taking 1,000 measurements, we can take millions of measurements with Infinite Focus, allowing us to enhance our end results and solutions.”

Through Focus Variation, a technology developed by Alicona, the system combines the focus of an optical system with modulated light and continuous vertical scanning to produce a topographic 3D data model of a component’s surface. According to the manufacturer, capabilities include full 3D surface characterization of forms; data presentation in true object surface color; simultaneous measurement of varying surface finishes; measurement and capture of step slopes, high “Z” ranges, roughness, wear, form and contour; full-form measurement of cones, cylinders and spheres; and placement of measurement profiles in the precise position requirements.

With this technology, EDM Department can model electrodes before burning them and measure cutters before use, both key advantages in its micromachining work, the company says. Additionally, the metrology system enables modeling parts on-site with 2 to 3 million measurements, comparing them to solid models and immediately sending results to customers via email. This has reduced lead times, improved customer response times and sped the iterative process from days to hours in some applications.

Although the ram EDM and the 3D optical metrology system each offer benefits of their own, the most significant improvements at EDM Department stem from the pairing of these two technologies, Mr. Raliegh says. For instance, the Infinite Focus’ inspection capability enables the shop to push the EDAC1 to new levels of precision, Mr. Raleigh explains, citing electrode production as an example. “With a better understanding of the surface being produced, we are now able to reduce the safety margin normally used, giving us better utilization and efficiency of our electrodes. The combination of the EDAC1 and Infinite Focus enables even better surface finish capabilities than initially thought—a 7-percent improvement—and we still have not utilized the machine’s full potential.”

He points out that when the company first purchased the EDM, it was able to achieve tolerances of ± 4 microns. Since adding the metrology system, it has been able to achieve tolerances of ±1.7 microns. In the past, many projects from existing customers had to be shelved because elements below 50 microns were simply not feasible, Mr. Raleigh says. Now, the company can produce, measure and see elements measuring less than 20 microns with stable and accountable processes. This has dramatically enhanced its microtolerance production capabilities and opened the door for several new opportunities.

Looking to the future, the company hopes to push for even tighter tolerances and accuracies, Mr. Raleigh says. “Because of these two new technologies, we will one day be able to say ‘now accepting 1-micron tolerances,’” he concludes.

Related Content

Understanding Errors In Hand-Held Measuring Instruments

Different instruments (and different operators) are prone to different errors.

Read MoreHow to Choose the Correct Measuring Tool for Any Application

There are many options to choose from when deciding on a dimensional measurement tool. Consider these application-based factors when selecting a measurement solution.

Read MoreChoosing the Correct Gage Type for Groove Inspection

Grooves play a critical functional role for seal rings and retainer rings, so good gaging practices are a must.

Read MoreWhat Should Machinists Know About In-Machine Probing?

In-machine probing doesn’t reach the power of CMMs but can still be useful for pre- and mid-process control, as well as for “rough screening” of parts.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)