Engineering Employees

Today, the lack of skilled manufacturing employees is the major problem holding this company back. To clear the way for growth tomorrow, the company is determined to solve this problem. The answer is an internal university for developing the skills of every current employee and new hire, including many who have never set foot in a machine shop before.

American Micro has the technology and it has the opportunities. It just doesn’t have the personnel.

The Batavia, Ohio, specialist in fine-precision machining is turning down business even though it has capable, high-value CNC machine tools sometimes sitting unused on the shop floor. The company just can’t find enough skilled employees to keep the machines producing at their full potential.

“We have customers who would triple or quadruple their business with us, if only we had the capacity,” says company president Stephen Kappers.

The company has recruited machinists throughout the United States. It continues to try this, in fact. However, it has limited success persuading established machinists—many of whom have lived in one area all their lives—to relocate their families to southwestern Ohio. Thus, the problem of having too few skilled manufacturing employees seems unsolvable.

In fact, it is unsolvable—at least today. American Micro is largely resigned to this.

But tomorrow, the problem can be solved.

American Micro needs to grow. It needs to grow soon. For reasons to be outlined in a moment, the company needs to expand and the Batavia facility needs to become even more technologically advanced. As a result, the staffing problem can only become more acute. Therefore, the company is determined to make a change, committing staff, time, space and capital equipment toward a plan for ensuring that its future staffing needs will be fully met.

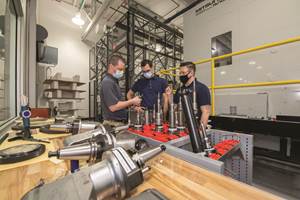

The company has established and staffed up a human resources department that includes certified trainers and an experienced director of human resources. Employing such a group may be unusual enough for a manufacturing plant of about 250 people, but the mandate of this group represents an even farther-reaching commitment. The group is helping American Micro develop an internal university. Dozens of technical classes, ranging in length from 4 to 40 hours each, are being developed by the company and taught within the company. Space, resources and machine tools are set aside specifically for training. Employees choose courses they want to take according to the career-development plans they want to follow, and they take these classes on company time. Soon, every employee will know specifically which classes are required for him or her to advance to a higher compensation level and/or to qualify for application to a different department. Training coordinator Bill Davis says he now finds himself teaching at least one class to some group of employees every day. That instruction then continues on the production floor through senior-level employees who act as on-the-job coaches. Thanks to this commitment to internal education, American Micro expects to alleviate its worries about finding skilled employees. The company will grow its own skilled employees from the inside.

Training Tradition

Gerard Paroz, when he founded the company 50 years ago, would have recognized and understood this commitment. The Swiss immigrant grew up in a culture where machinists learned their trade within a company. In the early days of his own company, the Swiss-type lathe was so unfamiliar in America that he had to train his earliest employees on his own.

In later decades, American Micro could rely on attracting not only highly skilled job applicants, but also local vocational school graduates with at least a strong foundation in machining. Only in recent years did that change. Local vocational schools have discontinued machining programs for lack of student interest. Bill Davis, who now teaches for American Micro, is himself a former vocational school instructor. The challenges he faces today are in some ways opposite to what he faced as part of a struggling academic program (see article on the previous page).

Growing To Stay Ahead

Today, the company CEO is Pierre Paroz, son of the founder. American Micro’s focus on precision work has not changed in 50 years, but the changing scope of its customers’ markets has forced the company to adjust its thinking in a variety of ways. Much of this thinking has focused on China, but not in the way you might think. Rather than Chinese competition, American Micro confronts pressure resulting from Chinese opportunity.

American Micro’s key customers are large OEMs making engines, control systems and other highly engineered products. A number of these big OEMs have operations in China to serve the Chinese market, and some of these companies have told American Micro that they don’t want the company shipping them parts. Instead, they say the company should provide closer support by having a manufacturing facility of its own in China. Indeed, there is pressure to have production capacity close at hand within various international markets. As a result, American Micro now has a Chinese plant coming up to speed, and company executives say that an eventual facility in Europe seems likely, too.

However, engineering resources still reside in Batavia. That means all the most challenging parts the company takes on will have to be machined here, at least initially. Thus, even if the Batavia facility remains the size it is today, the percentage of complex, high-value parts machined here will have to grow as the foreign facilities send more of that work this way. But the Batavia facility will not remain the size it is today, Mr. Paroz says. It will grow. He says the company has to go after commercial opportunities it isn’t pursuing today, not just because those opportunities are there, but also because growth can give the company a lead that will be difficult to overtake. The company will face more intense competition as its customers increasingly engage suppliers throughout the global stage, he says. But if American Micro can get big enough, it can maintain enough available capital to continually invest in the very latest production equipment, keeping the Batavia headquarters more advanced and efficient than any vying competitors.

Leveraging Experience

That big-picture reality for American Micro has brought individual-size opportunity into the lives of many employees. Christine Breen is an example. Coming to the company less than two years ago with no machining experience, she began working with Swiss-type automatics and now works in the CNC Swiss-type department. The training and certification she has pursued within the company have brought her from entry level to the next higher level of experience here, and with some assistance, she now routinely oversees high-value Citizen, Hardinge and Star CNC lathes.

That assistance typically comes from David Runge, who has been with the company since 1989. He has reached the eighth level of training and certification for this department, which is one level short of changing his role and becoming a salaried employee (a move that has not tempted him so far). Mr. Runge is one of the most skilled CNC Swiss-type operators in the company. By serving as a guide and coach on the production floor, he leverages and multiplies the impact of his expertise. Ms. Breen is skilled enough to do most of what the machines require of her, but a challenge related to tool setting, for example, or a judgment call related to tool wear, might require Mr. Runge’s advice. He assists 14 employees including her. In fact, his example suggests how American Micro’s new, clearly defined structure for training and advancement serves purposes that go beyond just imparting basic skills. Leaders like Mr. Runge need to be developed for the future, too—particularly because many of the company’s most senior shopfloor staff members will retire relatively soon. The new career-development track provides for this ongoing leadership development, offering a clear path for achieving this level of seniority, compensation and skill to each employee who might have the potential.

University Expansion

There is still a lot to do. The structure of compensation, for example, is still being refined. This is challenging because every department has its own curriculum of courses for advancement. A given department might have 10 or more levels of advancement, and some departments call for more specific aptitudes than others—plus there is the need to offer shift differentials. The number of permutations therefore makes it difficult to fine-tune the compensation increments to ensure the pay structure is both effective and fair. The company is still working on not only developing and improving its course materials, but also getting this important structure working right.

Other pending improvements to the program will be more visible. The company will clear out one of its mezzanines to expand the space available for training. Part of this space will be taken up with more machine tools devoted to training. For now, the training area has only manual machines. Soon, CNC machines relocated to this area will allow CNC training to occur entirely independent of the production floor.

Taking CNC machines out of production in this way is actually one of the easier investments to make, given how the company is struggling with CNC machine tools going underused today. Thanks to these training machines, more sophisticated CNC machine tools in the future will have all the personnel they need to ensure that they keep on producing.

Related Content

3 Tips to Accelerate Production on Swiss Lathes with Micro Tools

Low RPM lathes can cause tool breakage and prevent you from achieving proper SFM, but live tooling can provide an economical solution for these problems that can accelerate production.

Read MoreBuying a Lathe: The Basics

Lathes represent some of the oldest machining technology, but it’s still helpful to remember the basics when considering the purchase of a new turning machine.

Read MoreCNC Machine Shop Honored for Automation, Machine Monitoring

From cobots to machine monitoring, this Top Shop honoree shows that machining technology is about more than the machine tool.

Read MoreDigital Twins Give CNC Machining a Head Start

Model-based manufacturing and the digital thread enable Sikorsky to reduce lead times by machining helicopter components before designs are finalized.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)