Filtration System Sifts Out Costs, Cycle Time

This lapping and grinding shop recently moved into fine grinding (otherwise known as flat honing). A filtration unit from Transor Filter ensured its new fine grinding machine could provide the fine surface finishes and tight tolerances for which it was designed.

Although machine tool technology continues to advance, even the most sophisticated models might perform at less-than-optimal efficiency without proper management of cutting fluids. Rockford, Illinois-based A-1 Lapping has first-hand experience with this issue. When expanding from traditional lapping to a new process on a new machine didn’t deliver the expected benefits, the company found that the problem wasn’t the machine itself, but the filtration unit. A system from Transor Filter (Elk Grove Village, Illinois) not only enabled the machine to perform as intended, but also reduced consumable costs and eliminated a step in the shop’s manufacturing process.

A-1 Lapping has provided contract lapping and grinding services for more than four generations. The shop’s efforts to deliver quality surface finishes, rapid turnaround and competitive pricing are carried on today by Jason Greenberg, whose great-grandfather founded the company. The shop’s customer base hails from a variety of industries, including aerospace, medical, hydraulic and automotive. Materials are also diverse, ranging from cast iron and stainless steels to powdered metal, bronze, carbide and plastics. Part runs range from a single piece to a million.

Initially, the company performed only single-side lapping. However, growing demand for finer surface finishes, closer thickness tolerances and increased parallelism of lapped parts spurred the Greenberg family to keep up with increasingly stringent customer requirements by continually investing in technology. Thus, it was a natural progression for the shop to expand to double-sided lapping, which provided more consistent surface finish, flatness and parallelism, Mr. Greenberg says.

A couple of years ago, the shop sought to implement another process: fine grinding (also known as flat honing). Compared to conventional lapping, fine grinding can process parts faster and hold equal or better tolerances, Mr. Greenberg says. "It’s also a much cleaner process," he adds. "Generally, lapping produces parts with dull, gray matte finishes, and overall, it’s a relatively dirty process. A fine grinder leaves a much more reflective surface finish while still holding the tolerances you normally see only with conventional lapping."

After perusing the market for a fine-grinding machine, the shop chose Stahli’s Model 1205. While A-1 waited for delivery, Stahli installed the smaller Model 705 to allow the shop to familiarize itself with the fine-grinding process and train its employees. The Model 705 came with a lab filtration unit from Transor Filter that Stahli had on-hand. "Without knowing any better at the time, we were unaware of the type of filtration that unit provided," Mr. Greenberg says.

When the new Model 1205 arrived, A-1 opted for a different filtration unit. This filter promised 20-micron filtration, as opposed to Transor’s guarantee of filtering to 1 micron. As a result, surface finishes and tolerances on parts processed on the new machine were noticeably worse than those processed on the Model 705 with the Transor system. Additionally, wheel dressing and cycle times were significantly longer. Although the shop noticed the difference in performance almost immediately, it took a while to realize that it was due to the filtration units rather than anything inherent to the machines.

"From a cost standpoint, we made the mistake of trying another filter manufacturer when we purchased the 1205," Mr. Greenberg explains. "Without knowing what we were getting into, we had the machine in-house for approximately 3 weeks before we decided we had made a mistake. We sent that filter back, contacted Transor, and had one of their units in here in about 6 weeks."

Transor systems’ filtering elements are composed of a stack of 9,000 paper discs with center holes. The discs, each of which measures only 0.003-inch thick and 1.5-inch in diameter, are pressed tightly together and assembled on a 36-inch-long, fluted rod. Each filter vessel contains 61 of these assemblies, which are referred to as "filter sticks." That translates to more than half a million individual paper discs in each vessel, the manufacturer says.

Oil flows from the OD to the ID of the filter sticks, and debris is deposited on the edges of the paper discs on the outside surface of the sticks. Referred to as edge filtration, this method results in oil filtered to 1-micron clarity, the manufacturer says. The filter sticks are automatically cleaned via compressed air, which is forced through from the OD to the ID. Debris is deposited in a bag for disposal.

Once the new unit was in place, A-1 realized the importance of maintaining clean oil with a consistent temperature in order to hold required tolerances. This is accomplished via a chiller in the filtration unit that maintains oil temperature within ±0.2°. "Just a few degrees of temperature change when you’re attempting to hold ±0.00005 tolerances can throw the part out of specification," Mr. Greenberg notes. "Even after consistent 12- to 16-hour runs, the Transor was able to keep the honing oil at a consistent temperature and also extremely clean."

The shop soon realized that the Transor’s benefits go beyond ensuring short cycle times, tight tolerances and fine surface finishes. First, it involves virtually no consumables. In contrast, the shop used between $150 and $200 worth of consumables every other shift with the other filter, a paper-bed-type unit with a roll. This wasn’t a problem with the Transor unit, thanks to automatic cleaning of the filter elements and the fact that the only required maintenance is disposal of the debris bag, which costs the shop approximately $20 a week.

Mr. Greenberg also mentions grinding wheel life and performance as part of the consumable savings. "Any time you have cleaner oil going to the grinding wheels, that means that much less debris that’s going across the surface of those wheels. So you see less wear over time with a much more accurate filtration system."

The shop has also found that the Stahli machine with the Transor system enables it to eliminate an additional washing step. The 1-micron-filtered oil in the filtration unit also acts as a rust preventative. "Even after running thousands of parts with lots of of stock removal, the oil stayed consistently clean" Mr. Greenberg says. "The parts come out of the machine so clean that we can package and send them to the customer as-is."

Related Content

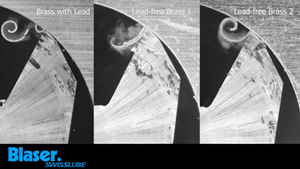

High-Speed Videos Analyze Machining Processes in Fine Detail

Blaser Swisslube captures the machining process, chip formation and behavior of its Synergy 735 metalworking fluid through high-speed, macro photos and videos.

Read MoreRego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Read MoreHennig Inc. Acquires Industrial Coolant Systems

ICS develops and field tests high-pressure coolant systems, coolant filtration systems and other machine tool solutions.

Read MoreSTLE Hosts Co-Branded Tribology, Lubrication Events

The 2023 STLE Tribology Frontiers Conference and Tribology & Lubrication for E-Mobility Conference will provide attendees with two opportunities to share and learn the latest tribology and lubrication engineering science.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)