Loading the player ...

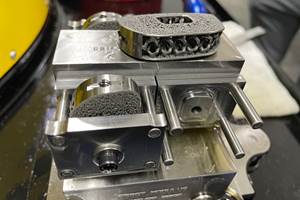

NuCon Corporation uses Hurco’s VMX42SR five-axis VMC to machine the swept surfaces and complex contours of this rotating, bladed component for an energy-industry customer.

Time is a precious commodity for all manufacturers. For contract shops, however, the importance of adapting quickly to changing conditions—and the consequences of not doing so—can be particularly significant. “In the business I’m in, you don’t get a lot of notification that the world’s going to end,” says David Bernhardt, co-owner of NuCon Corporation.

So far, Mr. Bernhardt has not been threatened with the end of his business (let alone the world), but he does have first-hand experience with the prospect of losing a lucrative job. Recently, a relatively new customer requested an order so large that the shop simply didn’t have the capacity to fulfill it. NuCon needed new equipment—fast. The machines that filled the niche, two identical VMX42SR VMCs from Hurco, have not disappointed. In addition to enabling the shop to keep its work, the five-axis machines have provided unexpected benefits. “They did exactly what we were looking for, and they’ve proven to be more profitable than I anticipated,” Mr. Bernhardt says.

Specifically, NuCon was looking for a five-axis machine that combined a relatively small work envelope with the rigidity and horsepower needed to cut hardened materials, particularly stainless steel. That alloy constitutes the majority of work at the Livonia, Michigan-based shop, a specialist in the machining of bladed, rotating components such as blisks and impellers for the aerospace, automotive and turbomachinery industries. NuCon produces virtually all types of blade configurations, including arbitrary shapes, open and shrouded impellers and open and closed turbines, among others.

Most of this work is conducted on 15 vintage, five-axis Sundstrand machining centers that the company has retrofitted with its own rotary spindle heads, custom impeller machining software and control system. Drawing on their experiences as machine tool designers in the 1960s, Mr. Bernhardt and fellow shop co-owner David Stormont developed these custom features when they founded NuCon in 1973. The Sundstrands vary in size to handle a variety of parts, ranging from those measuring only 5 mm in diameter to some that are cut from steel blocks as heavy as 11 tons.

For the most part, all the machines stay consistently busy. Recently, however, NuCon faced the prospect of two of its smaller machines becoming too busy, to the point of being overwhelmed. An energy industry customer had placed a larger order than usual for compressors and expanders used to liquefy natural gas, and the machines that would normally cut these parts had already reached capacity.

Tying up a larger machine with this work simply didn’t make sense, so Mr. Bernhardt and Mr. Stormont set out to see if they could find a new machine that would meet their needs. They soon discovered that, unlike the sturdy old Sundstrands, many smaller-envelope five-axis machines on the market were too lightweight for the application. In addition to lacking the necessary horsepower and torque, many of the models in the desired size range couldn’t even accommodate the weight of the parts. “About 750 pounds is where a lot of the table capacities fell off,” Mr. Bernhardt says. “The parts we’re looking at range from about 700 to 800 pounds before machining, so we’d have been running right on the ragged edge.”

Eventually, the shop owners’ search took them to Hurco’s technology center in Indianapolis, where a live stainless cutting demonstration convinced them that the VMX42SR would meet their needs. The 40-taper, five-axis VMC features 48 horsepower and a maximum spindle motor torque of 87 foot-pounds at 2,900 rpm. The machine’s 24-inch-diameter rotary table can handle loads as heavy as 1,100 pounds, more than enough to accommodate NuCon’s compressor and expander parts.

Mr. Bernhardt adds that the machine’s configuration was also a factor in his selection. Compared with other five-axis designs, this machine’s use of a B-axis tilting head plus C-axis rotary table provides improved tool access to the swept surfaces and complex contours that characterize most of the shop’s parts. For example, one strategy commonly employed at NuCon is to approach the part from underneath, or, as Mr. Bernhardt puts it, to “mill uphill, where the base of the spindle is lower than the tool tip.” Using a trunnion-type machine would limit this type of movement. “You can get boxed in, literally,” he says. “You can’t get all over the part like you can with a rotary head.”

Mr. Bernhardt and Mr. Stormont were also impressed with the machine’s motion control, a function of the toolpath algorithms in the Hurco CNC. Powered by the builder’s proprietary Win-Max software, the CNC also provides 600-block look-ahead, a maximum 600-ipm programmable feed rate and processing speed as fast as 2,277 blocks per second.

Best of all, the builder was prepared to deliver two of the machines almost immediately, and once installed, they provided additional, unexpected benefits. Although Hurco often touts intuitive conversational programming as a major selling point of its CNCs, NuCon uses the NC side of the control exclusively. Nonetheless, the control’s ease of use enabled operators to get up to speed on running the new machines quickly. Additionally, the company had no problems getting the CNC to integrate with either its custom software or the hyperMill CAM software from Open Mind (Needham, Massachusetts) it uses for especially difficult jobs.

“It really says a lot for us to go to another machine with an alien control when all of the Sundstrands and turning systems we have use the control system we developed,” Mr. Berhardt says. “The integration has been seamless, and all of the operators picked up the Hurco control quickly.”

Moreover, the machines require less attention than other models in the shop, and are therefore better suited to lights-out operation. In general, this is a result of the machines’ reliability, Mr. Bernhardt says. However, he cites table-mounted laser tool gages from Blum (Erlanger, Kentucky), which NuCon purchased as an option with the machines, as a major driver of increased confidence in lights-out operation compared with the Sundstrands.

Every machine in the shop, including the Sundstrands, has some form of integrated tool gaging. This enables the shop to avoid scrapping expensive parts by tracking tool wear to ensure cutters are changed when needed. Additionally, presetting tools on the machine helps ensure accuracy by avoiding distortion due to thermal growth in the spindle, differences in temperature on the shop floor, and other environmental considerations. However, most of these devices are contact-type units and are far less accurate than the models incorporated on the Hurco machines. “The lasers have given us greater confidence and really brought our lights-out operation up a notch,” Mr. Bernhardt says. “It’s so much more accurate that we don’t have to worry at all about the tool deteriorating and not catching it.”

Beyond the machines, Mr. Bernhardt says he appreciates the service and support provided by Hurco. As an example, he recalls one instance in which the tool clamping mechanism in one of the VMCs broke, rendering the spindle head virtually useless. Within two days of the accident, the builder had shipped another head to NuCon, installed it, and gotten the machine back up and running again. Mr. Bernhardt says this two-day turnaround is especially impressive because unique circumstances required Hurco to obtain the new spindle head from another user of the same machine, as opposed to shipping it from the factory. “They’ve been probably the best service network I’ve ever had,” he concludes.

.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)