Getting Concept To Car Faster

Joe Gibbs Racing applies a number of workholding techniques to speed the production of racing components its engineering team creates every day.

In terms of car development, one might think that a NASCAR race team primarily conceives and manufactures fresh part designs between seasons. That’s not the case. In fact, Joe Gibbs Racing (JGR) created some 1,200 new race car components at its Huntersville, North Carolina headquarters throughout all of 2008. Its substantial engineering department generates different designs each day as part of its efforts to continually improve car performance in a highly competitive racing environment. This puts pressure on JGR’s in-house machine shop to manufacture those components as quickly as possible so that the team’s drivers can immediately reap the benefits on the track. So in a sense, JGR’s manufacturing department is a job shop charged with creating small batches of various workpieces in short order.

To that end, JGR’s shop strives to reduce and simplify setups, just as all job shops do. JGR benefits because Schunk, which is located in nearby Morrisville, is its official workholding solutions provider. The shop uses a variety of Schunk workholding devices on its 18 Doosan HMCs, VMCs and turning centers (Doosan is a JGR technical sponsor).

For example, the first Schunk workholding device the shop used was a Magnos electropermanent magnetic chuck. Setups for a particular mounting plate were time-consuming because shimming was required to level the plate on the VMC prior to machining. Self-leveling pole extensions on the magnetic chuck eliminated the need for shimming, enabling both faster setups and improved tolerances. The magnetic chuck is also helpful in securing tubular components such as track bar sliders for machining. A track bar slider is a 2-inch-diameter tube that requires flats on opposite sides that must be milled parallel to each other. Using the magnetic chuck, the shop has been able to achieve parallelism of 0.0005 inch for those flats without distorting the tube.

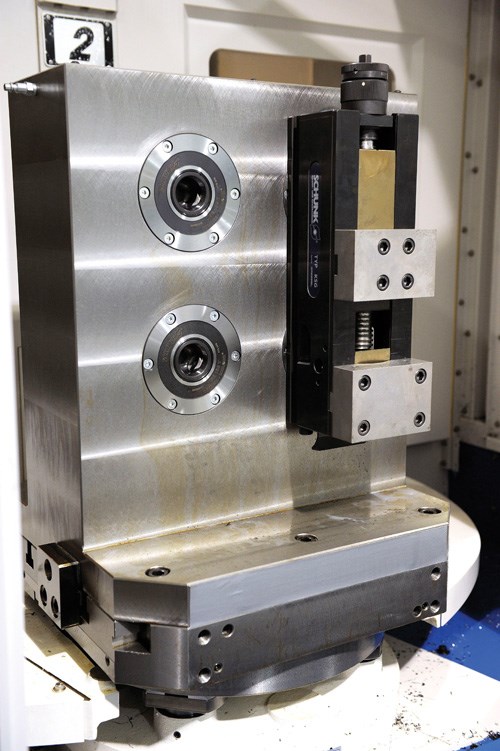

JGR’s shop also benefits by using Schunk’s Unilock quick-change pallet system. The photo on page 94 shows the system integrated into a tombstone used on one of the shop’s Doosan HMCs. The Unilock pallet modules on the tombstone provide a common mounting interface that accepts pins used on vises or fixture plates. The system is pneumatically released and spring actuated, and provides both quick installation of workholding devices and accurate positioning.

While the machine is running one job, parts for the next can be set up on the appropriate workholding device. The pallet system allows operators to quickly remove the fixture holding the completed parts and install the fixture with workpieces for the next job. The common mounting pin interface allows the shop to use any of its existing fixturing or vises with the pallet system. This system also allows JGR to interrupt a part run with a more urgent part without lengthy set up changes.

The Kontec KSM Rail multiple-part mechanical clamping system is another workholding device JGR uses on its machining centers. This system allows the shop to clamp numerous workpieces on a machine table for long stretches of unattended machining and improved throughput. It consists of a fixed jaw and one or more moving jaws on a clamping rail that adjust to secure parts of different sizes. The shop often uses multiple clamping rails on a machine’s table to maximize the number of parts machined in one setup.

The photos below show such applications. Alternator brackets like the ones shown were previously secured using two single-station vises on the table at a time. Using the Kontec system, the shop now sets up 12 parts per load for first operation and four parts per load for the second. This reduces tool changes and door openings, saving a total of 2 hours and 15 minutes for a batch of 50 parts. This also frees 7 hours for the operator to tend to other machines.

Machine operators in JGR’s shop are akin to members of the team’s pit crew. They must be able to quickly, yet precisely set up new jobs to minimize machine down time. The various workholding strategies that make this possible are key reasons why JGR can bring an engineer’s concept to a race car faster.

Related Content

Siemens and Mahle Partner to Develop Wireless EV Charging

Mahle will contribute its experience as an automotive supplier and Siemens will use its expertise in the field of charging infrastructure to develop wireless charging stations for electric vehicles.

Read MoreNew Laser Technology in Non-contact Optical Dimensional Metrology

LADAR technology from API sets a new standard in non-contact optical dimensional metrology for manufacturing industries.

Read MoreSunnen Products Company Partners With Hendrick Motorsports

The partnership puts the new Sunnen SV-series honing machine in the Hendrick Motorsports engine operation alongside other Sunnen honing and engine building machines.

Read MoreSandvik Coromant on Acquisitions: Solutions Entail More Than the Tool

A Q&A with global president Helen Blomqvist explores the cutting tool maker’s acquisition of CAM software companies and how this connects to, among other things, electric vehicles.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.jpg;width=70;height=70;mode=crop)