Getting To Know “Black Aluminum”

An introduction to CFRP

CFRP—it’s been called black aluminum, and its design and fabrication has been described as a black art. What is it, really? Carbon fiber reinforced polymer, or CFRP, is simply a combination of carbon fiber filaments in a matrix material. But the number of possible combinations is practically infinite, when you consider the range of fibers and the huge array of high-performance matrix resins available. In this article, we take a look at the basics of CFRP composites, how they’re created, what materials are typically used, as well as their advantages and representative applications.

Composites, like metal alloys, comprise two distinctly different components. Unlike metals, the two components, when combined, remain discrete but function interactively to make a new material whose properties can’t be predicted by simply summing those of the components. Fibers determine the overall mechanical properties of the part, while the matrix determines the overall physical properties of the part. The resin matrix transfers the applied forces to the embedded high-strength fibers, helps the part resist cracks and protects the fibers from damage due to environmental conditions like chemicals.

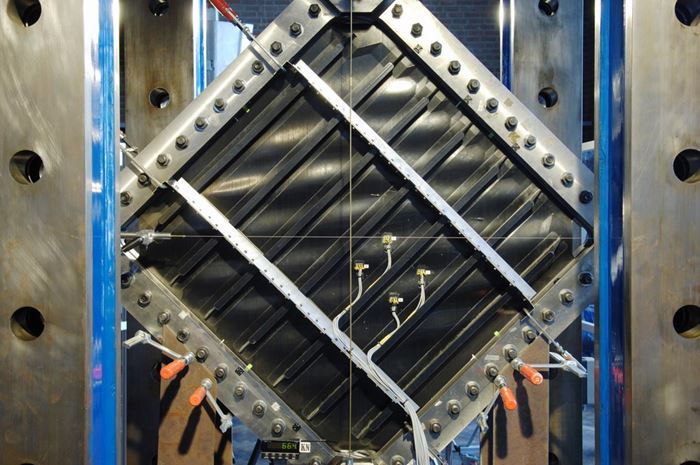

Design of a carbon fiber composite requires a good knowledge of how composites differ from traditional engineering materials and what effect those differences have on analysis and manufacturing. A composite part is defined by the orientation, thickness and fiber type in each “ply,” or fiber/resin layer—often referred to as fiber architecture. As compared to metals and plastics, which are relatively homogeneous in all directions, composite properties vary from ply to ply, but individual plies are assumed to be homogeneous. Typically, composites are made up of several plies with mutually perpendicular planes of symmetry, to create a “laminate” that is symmetrical and balanced. High fiber volume (more fiber than resin) creates a stronger and lighter part, like an aircraft wing, but one that is more expensive, since fibers cost more than resin. A lower fiber-to-resin ratio gives a heavier, more chemically resistant part—think composite piping at an oil refinery.

The String . . .

So, what type of fiber should you choose for your laminate? Carbon fiber—by far the most widely used fiber in high-performance applications—is produced from a variety of precursor materials, including polyacrylonitrile (PAN), pitch and (rarely) rayon. Fibers made with the precursor are heated and stretched to create the high-strength finished carbon fibers. PAN-based carbon fibers are the most versatile and widely used. They offer a wide range of properties, including excellent strength—to 1,000 ksi—and high stiffness. Pitch fibers, made from petroleum or coal tar pitches, have high to extremely high stiffness and low to negative axial coefficient of thermal expansion (CTE), often useful in spacecraft applications that require thermal management, such as electronic instrumentation housings. PAN- and pitch-based carbon fibers are available with moderate (33 to 35 Msi), intermediate (40 to 50 Msi), high (50 to 70 Msi) and ultrahigh (70 to 140 Msi) modulus—the mathematical value that describes the stiffness of a material by measuring its deflection or change in length under loading.

Carbon fiber manufacturers produce carbon fiber bundles or “tows” consisting of thousands of continuous, untwisted and delicate filaments, much thinner than a human hair, with the filament count designated by a number followed by “K,” meaning multiplication by 1,000. So, 12K tow indicates a bundle containing 12,000 continuous filaments. Typical aerospace composite applications use finer tow sizes ranging from 1K to 12K. Newer heavy-tow carbon fibers, with filament counts from 48K to 320K, are available at a lower cost than aerospace-grade fibers, because of precursor and processing differences. They typically have a slightly lower modulus and tensile strength, and are used when fast part build-up is required, most commonly in recreational, industrial, construction and automotive markets. Though strong, carbon fibers are less impact-resistant than glass fibers and also can experience galvanic corrosion when in contact with metal. Fabricators overcome the latter problem by using a barrier material or veil ply—often made with fiberglass/epoxy—during laminate layup, to prevent direct contact.

Other high-performance composite fiber choices include aramid (often referred to by its trade name Kevlar), composed of aromatic polyamide. Aramid fibers provide exceptional impact resistance and tensile strength. Standard high-performance aramid fiber has a modulus of about 20 Msi and tensile strength of approximately 500 ksi. Aramid’s properties make the fiber an excellent choice for helicopter rotor blades, ballistic protection, solid rocket motors, compressed natural gas (CNG) tanks and other parts that must withstand high stress and vibration. Also on the list is high-strength, high-modulus polyethylene (PE), known for extremely light weight, excellent chemical and moisture resistance, outstanding impact resistance, antiballistic properties and low dielectric constant, as well as relatively low resistance to elongation under sustained loading and an upper temperature use range of about 98°C/210°F. At least one aircraft manufacturer now uses high-modulus PE fibers for the bulletproof insert in aircraft cockpit doors. High-strength glass fibers, quartz fibers, ceramic fibers, basalt fibers, boron fibers and fiber hybrids are other options.

And The Glue

The resins used to make CFRP parts fall into two broad categories—thermosets and thermoplastics. While both consist of molecular polymer chains, a thermoset resin permanently cures into a cross-linked network when mixed with a catalyst, exposed to heat, or both. Fabricators can control the cure profile and viscosity through careful formulation of the catalyst package, which may include inhibitors, promoters and accelerators. For aerospace applications using CFRP, cure takes place in an airtight autoclave vessel, which applies heat and pressure to ensure good consolidation of the laminate to minimize any voids or air bubbles that can weaken the part. Thermosets are the predominant matrix materials used to create CFRP composites — although there are many high-performance thermoplastic resin matrices available, such as polyetheretherketone (PEEK), which are finding their way into critical aircraft structures like access doors and panels and wing leading edges.

While unsaturated polyester resins are the most widely used in commercial, mass-produced composites applications such as bathware or boats, thanks to their ease of handling, good balance of mechanical, electrical and chemical properties and relatively low cost, they are not used with carbon fiber in advanced high-performance applications because they have relatively high shrink rates. For advanced composites, the most common thermosets are epoxies, phenolics, cyanate esters (CEs), bismaleimides (BMIs) and polyimides.

Epoxy resins contribute strength, durability and chemical resistance to a composite. They offer high performance at elevated temperatures, with hot/wet service temperatures up to 121°C/250°F. Epoxies come in liquid, solid and semisolid forms and typically cure by reaction with amines or anhydrides. Many aerospace applications use amine-cured, multifunctional epoxies that require autoclave cure at elevated temperatures. Toughening agents, e.g., thermoplastics and reactive rubber compounds, can be added to counteract brittleness.

Phenolic resins find use for flame-resistant aircraft interior panels and in commercial markets that require low-cost, flame-resistant and low-smoke products. Excellent char yield and ablative (heat-absorbing) characteristics have made phenolics long-time favorites for ablative and rocket nozzle applications. However, their mechanical properties are somewhat lower than those of epoxies and most other high-performance resins. Cyanate esters (CEs) are versatile matrices that provide excellent strength and toughness, allow very low moisture absorption and possess superior electrical properties, compared to other polymer matrices, although at a higher cost. CFRPs made with CEs find use in radomes, antennae, missiles and ablatives to microelectronics and microwave products.

Among the more exotic of resins, bismaleimide (BMI) and polyimide (close relatives, chemically) are used in high-temperature applications on aircraft and missiles (e.g., for jet engine nacelle components). Polybutadiene resins offer good electrical properties and chemical resistance and have been used successfully as alternatives to epoxy in E-glass/epoxy composites typically used to mold thin-walled, glass-reinforced radomes. Benzoxazines, a subclass of phenolic resins, are formed by reacting a phenol with an aldehyde and an aromatic amine. Finally, phthalonitriles have service temperatures approaching 371°C/700°F, and have been selected for high-temperature engine parts as well as components in submarine vessels.

Fabricators of composite parts buy the fiber form and resin best suited to their applications. Carbon tows are routinely woven to form cloth of various weaves and weights, braids, unidirectional tapes or multiaxial fabrics — a construction combining fibers in several different orientations. For aerospace applications, resin-impregnated fiber forms, commonly called “prepregs,” are manufactured by impregnating dry fibers with a controlled amount of resin (thermoset or thermoplastic), using solvent, hot-melt or powder impregnation automated technologies. Prepregs have to be refrigerated in a “B-stage,” or partially cured, state until they are needed for fabrication. Prepregs deliver a consistent fiber/resin combination and ensure complete fiber wetout, critical for high-performance aerospace uses like Boeing’s new 787 Dreamliner aircraft. They also eliminate the need to weigh and mix resin and catalyst for wet layup.

Of the methods available to manufacture composite parts, the most basic for thermoset composites is hand layup, which typically consists of laying dry plies or prepreg plies by hand onto a hard tool to form a laminate stack. If dry fibers are used, resin is applied by means of resin infusion or, in a variation known as wet layup, each ply is coated with resin and “debulked” or compacted after it is placed. Automated methods are growing, as fabricators seek to reduce composite part costs. These include filament winding, pultrusion, automated tape laying (ATL) and automated fiber placement.

Are They Better Than Metal?

Composites offer a combination of high strength and stiffness with low weight that beats virtually any other material. Other advantages offered include tremendous design flexibility—the ability to create complex, curved, tapered or aerodynamic shapes. Designers can also achieve good vibration damping, low CTE, fatigue load resistance, part consolidation and fastener elimination, good performance in harsh environments with resistance to corrosion and wear, which leads to lower overall life cycle costs. The push for greater fuel economy in the face of astronomical fuel costs, for example, is pushing composite materials into automotive and aerospace applications like never before. Perhaps the most dramatic illustration of CRFP’s growing incorporation into the mainstream is its use on the Boeing 787 and the Airbus A380 aircraft, both now in production—significant portions of each plane’s airframe is made with CFRP. Wind turbine blades, satellites and launch vehicles, automobile components, naval vessels, industrial rollers, and many more applications are benefiting from CFRP, and the trend is increasing. The black art is now in the spotlight.

Related Content

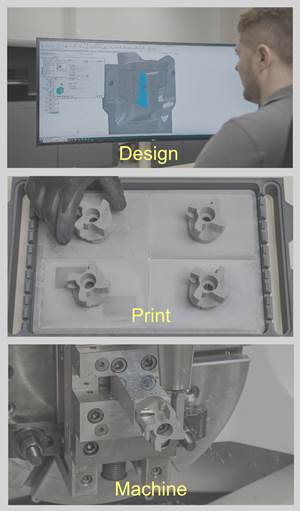

SolidCAM Wants to Help Machine Shops Get into Additive Manufacturing

SolidCAM's partnership with Desktop Metal is aimed at making additive manufacturing more accessible to job shops and other manufacturers.

Read MoreBest Practices: Machining Difficult Materials

Cutting hardened steel, titanium and other difficult materials requires picking the right tools, eliminating spindle runout and relying on best practices to achieve tight part tolerances.

Read MoreHorizontal High-Speed Machining Saves Hundreds of Work Hours

High-speed machining is the latest change at Blair-HSM South, helping this once old-fashioned shop improve productivity and morale while enabling new work.

Read MoreBeyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreRead Next

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More

.png;maxWidth=300;quality=90)