Going Live on a Vertical Lathe

For this company, investing in live tooling and a high-pressure coolant system on a pair of new CNC vertical lathes eliminated setups, increased throughput and led to safer material handling on the shop floor.

New machine tools are often purchased in order to fulfill a contract for a specific part. Beyond meeting this goal, however, additional benefits to a company’s operations can usually be identified. That’s what Sterling Engineering Corp. discovered after investing in a pair of powerful vertical turret lathes with two options that were new to them: live tooling and a high-pressure coolant system. The “value-adds” they’ve found include reduced setups, a streamlined workflow, increased capacity and even a safer shop floor. Plus, the shop continues to become more effective with these machines by applying the lessons learned in utilizing these two features.

“Although we did purchase these machines for a particular job, they have also allowed us to rethink how we approach machining other parts so that we can do it more quickly and with fewer setups,” according to Chris Haddad, general manager. “Having these new capabilities has also given us the ability to quote work we couldn’t have handled as easily before, if at all, since being able to do more on a machine leads to less material handling, lowering our manufacturing cost per part. The live tooling allows us to cut features on parts that once had to be run across another machine, which saves an incredible amount of time and labor, and the high-pressure coolant increases material removal since the tool can stay in the cut longer and with less chance of breaking an insert. We’re very happy with how well these two VTLs are performing, and with the improvements they’ve made to our overall operations.”

Sterling Reputation

Founded in 1941 in Barkhamsted, Connecticut, by John Lavieri—a toolmaker—and his brother Daniel, Sterling Engineering was originally a small tool and die shop that was housed in the family’s dairy barn. It worked almost exclusively with what was then known as the Vought Sikorsky Co., which was engaged in developing the Corsair fighter plane. As the company grew, its emphasis shifted from toolmaking to contract machining work. It still counts Sikorsky as a significant customer, in addition to Pratt & Whitney, GKN, General Electric, MB Aerospace, and Alcoa. Primarily involved in aerospace, Sterling also serves the power generation and heavy industry markets. As of March 1, the company is a wholly-owned subsidiary of the Air Industries Group, based in Bay Shore, New York.

While quoting a new job in 2012, Mr. Haddad and his colleagues looked closely at their equipment lineup, deciding it was time to invest in new vertical lathes that would increase their capacity, simplify their machining processes and help them produce the more-complex geometries required by its aerospace customers. This began an examination of the machine tools and accompanying features that were currently available—a process that suddenly escalated when they landed the new contract. “There was a new sense of urgency once the contract was finalized,” Haddad recalls, “especially since it depended on the added capabilities the new machines would provide. We knew it was time to narrow down our list and make a decision so we could get started machining this part.”

As luck would have it, this occurred at the same time that IMTS was being held in Chicago, which afforded a great opportunity to take a close look at dozens of vertical lathes and to meet firsthand with their OEMs and distributors. After visiting 15-20 booths during the show, Mr. Haddad finally decided to focus on three machine lines that his research indicated would meet Sterling’s needs. And that’s when the real work began.

Due Diligence

Equipped with dozens of sturdy machine tools such as CNC horizontal and vertical machining and turning centers bearing the logo of OEMs including Giddings & Lewis, DMG MORI, Mazak, Pratt & Whitney, Gray and Cincinnati Milacron, Mr. Haddad was struck by the increased presence of manufacturers from Asia at IMTS, and also by the quality of their representation in the States. Of the finalists in his equipment search, one is located in Japan, another in South Korea and the third in Taiwan. Based on introductions made in Chicago, he reached out to the U.S. distributors for these three lines and began putting them through their paces, gathering specifications and asking detailed questions. In one instance he was able to visit a technical center to see demonstrations run on the actual machine he was considering, and in another he visited an end user to get feedback on the machine’s real-world operation. In all instances, he was given referrals to contact by phone.

“We factored in price and availability, of course, but after all the research we’d done the decision really came down to something quite simple,” Mr. Haddad says, “and that’s ergonomics. We found that, in addition to being powerful and accurate, the design of the Honor Seiki machine provided the operator with the best access to the worktable, not only being able to reach and manipulate the workpiece but to do so without causing back strain or some other avoidable injury.”

Distributed in the United States by CNC Systems Inc. of Kennebunk, Maine, Honor Seiki Co., Ltd.—a member of the Tongtai group—is based in Kaohsiung City, Taiwan. Although Honor Seiki specializes in CNC vertical lathes, it also manufactures vertical turning centers, high-speed drilling center, vertical grinding centers and complete production lines, including robotics, for the aerospace and ground transportation markets.

Stephen Arcari, president of CNC Systems, assisted Sterling in making their decision. “I listened to what they wanted to do, and I ended up suggesting they look into the VL-160CM heavy duty vertical turning center,” he says.

Mr. Arcari says that technical specifications for the three-axis VTL include a max. swing and cutting diameter of 78.7 inches and a max. cutting height of 49.2 inches. The machine can handle workpieces up to 17,600 lbs and has a 16-unit tool changer. “Overall machine rigidity is due to the machine’s cast Meehanite base,” he says, “and the VL-160CM is heavily ribbed for reduced vibration and thermal distortion during heavy machining.”

With the decision made, the machines delivered, aftermarket options such as the high-pressure coolant system installed and initial training completed in 2013, the company was poised to begin machining parts for the new order. And then, for reasons completely beyond Sterling’s control, the contract fell through.

Shifting Strategy

In yet another example of how conducting research in advance really pays off, Mr. Haddad had considered the possibility of losing the order before investing in the machines, thinking of how the two VTLs could be used to complete existing work more efficiently or even to seek out new business. Due to this foresight, the machines did not sit idle.

Brian Bidwell, a former contractor at Pratt & Whitney, joined Sterling Engineering as a manufacturing engineer of CNC programming about six months after the first Honor Seiki VTL had been installed. In fact, they were part of the reason he was attracted to the position. “Any machine operator wants to learn about the latest technologies, and I’d never worked with live tooling and high-pressure coolant before,” he says, “so that was a really attractive proposition for me.”

The company had already begun assigning new work to the machines once Mr. Bidwell arrived, so he set himself to work learning everything he could about the lathes and how those two features, in particular, could be implemented fully. The benefits of both were immediately apparent.

As one can easily imagine, a live spindle on a VTL allows procedures such as milling to be performed on the same machine that handles turning operations. “We had an exhaust case that required a single keyway to be cut, for instance,” he says. “Without live tooling it took moving the part to another machine and going through all the fixturing just to make that one cut, which was really time consuming. Now that’s just one more operation that we can perform on the same machine, without having to do an additional setup.”

He also points to irregular shapes, such as another part the company manufactures with an ovoid ID, that can be machined with live tooling more quickly, easily and accurately than was possible using prior methods. Another somewhat unexpected benefit involves worker safety. “We were considering a large, heavy part that required a series of holes to be drilled around its circumference at an angle,” Mr. Haddad says. “Before we had the VTLs with live tooling we had thought about drilling them on a horizontal boring mill, with the part cantilevered off of the worktable. We would have had to use a quill spindle, so sagging of the cutting tool was a major concern. The operator would have to move the part around with a hoist to get the right positions for the holes, and it was just a nightmare from a safety standpoint. Now we are able to mount the part on the VTL, it’s extremely stable, and we can get everything we need done on one machine. The fewer times you have to reposition a large workpiece, the safer it is for everyone in the area.”

As for the high-pressure coolant system—a ChipBlaster JV-40 in this instance, which delivers a maximum of 1,500 psi—Mr. Bidwell says the primary advantage involves chip evacuation. “We produce certain families of parts that have deep grooves, and the process generates bird nest-type chips, which can foul the tool path pretty quickly,” he says. “The coolant system helps break the chips, clears the path and allows us to continue machining the feature.”

Other benefits include penetration of the air barrier that can exist between low- or medium-pressure coolant spray and the surface of the workpiece, which helps dissipate heat and prevent deformation of both the part and the cutting tool, preserving tight tolerances and leading to a higher-quality surface finish. The cooling jet helps create the low, stable temperatures required to allow the tool to stay in the cut longer, and to operate at faster cutting speeds, with less chance of insert failure. “And that really helps when you’re machining large workpieces like we do,” he says, “where you calculate ‘inserts per part’ rather than ‘parts per insert,’ as you do with smaller pieces. It can get expensive replacing them, so you want those inserts to last as long as they can.”

Mr. Bidwell continues experimenting with the new VTLs, and especially the added capabilities that live tooling and high-pressure coolant system provide, constantly thinking of ways to machine existing parts more efficiently, and also to attract new customers due to the expanded capabilities these machines, and their high-tech options, provide.

Lessons Learned

When it comes to the live tooling feature, Mr. Bidwell points to three primary areas in which important lessons have been learned.

- Whether to program in polar interpolation mode (G112) or point to point mode. “I initially tried programming all cuts without polar interpolation, but found it was much harder to tell what was going on,” he says. “Polar interpolation allows for simpler code more similar to regular three-axis mill programming, so I can rely on the machine control to do most of the work. We still use point to point for drilling type operations.”

- How to make the most of limited tool capacity. “For a hole deburring operation I switched from two tools for producing top and bottom corner radii to a Heule COFA tool,” Mr. Bidwell says. “This let one tool finish both sides of the hole and saves space in the carrousel.”

- Dialing back feeds and speeds due to lower rpm of the milling spindle.

As for the high-pressure coolant system:

- It allows for more stable cuts with ceramic tools. “The directed volume of coolant lets ceramic inserts run for a little longer tool life in superalloys like Inconel 718 or Haynes 188,” he says. “We’re able to push tools for another minute or two in the cut before rotating. During a heavy roughing operation this can really improve the productivity with ceramics.”

- Chip evacuation in deep grooving is greatly improved. “In one application I’m able to get chips out even when the tool is three inches deep in a face groove,” he explains.

- The importance of aiming nozzles properly to get coolant on the cutting edge. “Otherwise you’re just spraying it everywhere,” he says.

Mr. Bidwell is also pleased with the Honor Seiki’s proprietary rigid tool clamping system, with an oversize Z-axis cast-steel ram incorporating a curvet coupling and T-type pull stud for secure, programmable tool holding. “We found we were able to replicate heavy cuts that the older VTLs do with the ‘solid lock’ tool retention,” he says, “which is extremely stable. Higher rigidity leads to lower vibrations and, ultimately, better surface finishes and longer tool life.”

Related Content

Can Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreWill the “Great Resignation” Become an Opportunity for Manufacturers? Get Ready for the Returning 3 Million

The Great Resignation will become a Great Reapplication when employees currently able to stay out of the workforce return to it looking for something better. Machining employers that are already evaluating candidates for fit, without demanding specific skills coming in, might be positioned well to draw upon this wave.

Read MoreWhen Handing Down the Family Machine Shop is as Complex as a Swiss-Turned Part

The transition into Swiss-type machining at Deking Screw Products required more than just a shift in production operations. It required a new mindset and a new way of running the family-owned business. Hardest of all, it required that one generation let go, and allow a new one to step in.

Read More8 Ways to Increase Productivity on the Manufacturing Floor

When it comes to machine shop productivity, continuous improvement depends on efficient employees, equipment and processes.

Read MoreRead Next

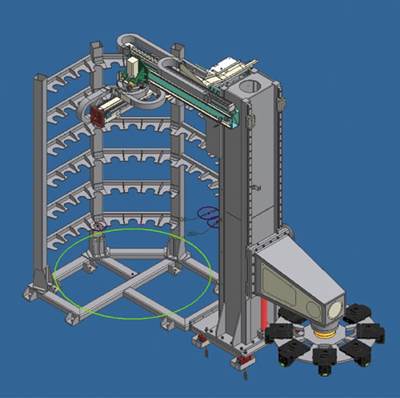

The Case for VTLs

The vertical lathe configuration offers advantages that go beyond large-part machining.

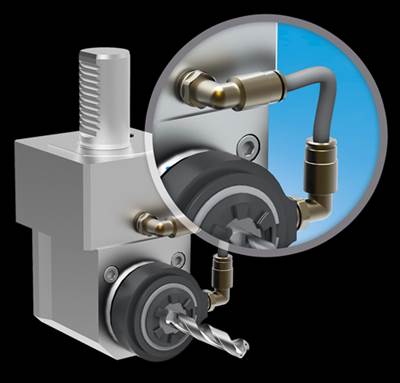

Read MoreExternal-Coolant Live Tooling Heads Get an Upgrade

One of the most important aspects of effective coolant usage is precise delivery to where it is needed in the cut.

Read MoreVTL Delivers Powerful, Heavy Cuts

In addition to high horsepower and torque for heavy cuts in difficult-to-machine materials, the Powerturn 2500 C-M vertical turning lathe offers a large-capacity ATC, thermal stability and observation cameras mounted within the work zone.

Read More

.png;maxWidth=300;quality=90)