Grinding’s Role In A Thermal Spray Shop

Cylindrical grinding is the final step in bringing worn components back to size after applying a build-up coat of molten metal.

Nifty additive and subtractive metalworking technologies blend at St. Louis Metallizing (SLM), located in the city that shares its name. The additive is thermal

spray; the subtractive is the cylindrical grinding of the sprayed molten metal.

The thermal spray process melts metal by flame or electrical means, and then sprays the atomized material onto a substrate. It is typically used to build up the surface of a worn component, such as a printing roll, for subsequent precision grinding back to OEM size specifications.

Neither thermal spray nor grinding is a new manufacturing concept, but the sophistication of technology for related equipment has risen over the years. SLM remains proactive in adopting leading manufacturing technologies. For thermal spray, it has flame, electrical-arc, plasma and high velocity oxy fuel (HVOF) application capabilities in-house. For grinding, it has integrated CNC machines with superabrasive wheels. Its newest CNC machine features multiple-diameter, in-process measurement capability to boost throughput of large-diameter rolls up to 4 meters in length.

Joseph Stricker, SLM’s president, says that printing roll refurbishment accounts for 50 percent of the company’s work. Typically it is the roll’s printing and bearing surfaces that become worn from use. First, SLM turns these areas undersize or, in the case of rolls that have previously been coated, the existing coating is stripped away via waterjet. Next, the thermal spray coating is applied and the roll is ground typically to ±0.0002 inch in roundness and 0.0005 inch total indicator runout (TIR) from end to end. This degree of precision is necessary no matter the roll’s length to ensure print quality.

During a tour of the shop, Mr. Stricker explained the process behind refurbishing a printing roll using thermal spray and highlighted grinding’s role in bringing such large, precision components back into shape.

Material Differences

Thermal spray is a mechanically bonded coating that is melted and sprayed at a high velocity toward a workpiece’s substrate. After application, the coating cools and shrinks around the substrate, which creates the adhesion. The typical thermal spray materials SLM applies are nickel-based alloys and 316 or 420 stainless steels. Thermal sprays are often used as an alternative to chromium plating because of their corrosion resistance. However, their composition is not the same as wrought material of the same type. Because molten metal is atomized during delivery to the substrate, some oxide is created. These oxidized bits can have a higher hardness rating than surrounding material. The coating also tends to be a bit porous—its microstructure resembling that of cast iron.

Although thermal spray thickness is theoretically limitless, it commonly ranges from 0.005 to 0.2 inch for SLM’s standard applications. The spray thickness depends on how many times the roll has been repaired. A roll can continue to be repaired as long as its substrate remains in good condition, which, according to Mr. Stricker, can extend service life to more than 20 years.

The Grinding Machine

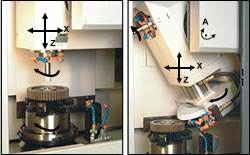

SLM currently has four CNC grinders in addition to some manual machines. The biggest CNC—also the busiest—is its Danobat HG-91 cylindrical grinder with dual wheelheads and B-axis rotation of +30/-30 degrees. Danobat’s worldwide headquarters is located in Elgoibar, Spain; its U.S. office is in Elk Grove Village, Illinois.

The shop benefits from this dual wheelhead design because it can mount both a roughing and finishing wheel on the machine, which greatly reduces changeover times between operations. The machine also can grind both ends of a workpiece using angled grinding wheels without flipping the workpiece. Considering the size of the printing rolls, this is especially helpful. The heaviest roll that has been ground in the Danobat weighed 4,500 pounds, although the machine is said to have the capacity to grind 10,000-pound workpieces. Obviously cranes abound within SLM’s facility.

SLM often first performs a proof-grinding operation of the thermal spray to approximately 0.005 inch oversize. Proof-grinding to a slightly larger diameter ensures that the integrity of the thermal spray coating is high. The company then assembles bearings and other roll components before finish grinding the roll to size.

Machine rigidity is key for effective grinding of many of these rolls. This is not so much a function of the thermal spray coating as it is the roll’s geometry. These rolls commonly have a slot that runs the entire length of the roll. The slots, which can be many inches wide, cause an interrupted grinding situation. The grinding wheel is under pressure as it remains in contact with the continuous portion of the roll’s print surface. So, as Mr. Stricker explains, when the wheel reaches the slot, it wants to push into that void. If that were to occur, then the wheel would tend to dig into the opposite edge, causing the slot to be out of tolerance. Mr. Stricker notes that the shop does not alter wheel or workpiece rotational speeds for interrupted versus continuous grinding operations. The important factor is to have a machine with the rigidity to maintain accurate wheel position throughout the interrupted operation.

SLM uses either diamond or blended aluminum oxide grinding wheels from Norton Abrasives (Worchester, Massachusetts). The wheel choice largely depends on the type of material being ground. Aluminum oxide is generally used for iron-based and nickel-based alloys. The superabrasive diamond wheels are used for very hard coatings, such as ceramics and carbides. The frequency with which the wheels are dressed depends on the size of the workpiece and the type of thermal spray material that has been applied. Nickel-based alloys tend to fill up a wheel’s grain structure quickly, so more frequent dressing is needed to open the wheel’s cutting face and expose the abrasive grains. Flood coolant delivered directly to the grinding zone is mandatory for all grinding operations. SLM uses a specially formulated, water-based coolant blend that was developed by a local supplier.

The Process

Because the shop had experience with CNC grinders, there was no big learning curve associated with programming the new Danobat grinder. In terms of programming, the main differences between the new machine and the existing CNCs were making the most efficient use of the new machine’s dual wheelhead design and in-process gaging. Mr. Stricker notes that programming for those capabilities was not difficult for his workers to pick up.

In-process gaging improves throughput because part measurement can be performed while the machine is grinding. An operator need not interrupt the process to perform manual measurement—grinding can continue until the workpiece feature reaches its specified diameter. That is especially helpful when multiple diameters are being ground on a workpiece, Mr. Stricker says.

The machine’s multi-diameter measuring system is able to measure workpieces ranging in diameter from 30 to 300 mm to a precision of ±0.002 mm. In addition to workpiece diameter, the system can also automatically determine roundness, cylidricity, straightness and taper—all critical characteristics for a precise printing roll.

Added Benefit To High-Technology

Establishing advanced manufacturing practices has allowed SLM to stay put not just in a business sense, but also in terms of its facility’s location. Some years ago, the city decided to redevelop and recast the area surrounding SLM as a biotechnology zone. However, SLM’s immediate area was excluded from that plan after the developer toured the shop and saw that the company was already providing quality jobs using high-technology equipment.

Related Content

How to Reduce Cycle Times by 70% and More on Your Existing CNCs and Dramatically Improve Tool Life Too

By employing advanced high efficiency milling techniques for the entire machining routine, SolidCAM’s iMachining technology can drastically reduce cycle times while vastly improving tool life compared to traditional milling.

Read MoreChoosing a Five-Axis Machine Tool With Automation in Mind

While much focus is placed on the machinery that moves parts, the features most important for automating five-axis machining are arguably found in the machine tool itself.

Read MoreWhen Organic Growth in Your Machine Shop Isn’t Enough

Princeton Tool wanted to expand its portfolio, increase its West Coast presence, and become a stronger overall supplier. To accomplish all three goals at once, acquiring another machine shop became its best option.

Read MoreA New Milling 101: Milling Forces and Formulas

The forces involved in the milling process can be quantified, thus allowing mathematical tools to predict and control these forces. Formulas for calculating these forces accurately make it possible to optimize the quality of milling operations.

Read MoreRead Next

Vertical Grinding Has Advantages

In vertical grinding, the workpiece is held upright in a rotary chuck with the grinding spindle overhead. This configuration can improve roundness, facilitate single-setup processing and prolong the life of the machine. Loading and unloading may gets easier, too. Workpieces with relatively large diameters and short lengths benefit the most from vertical grinding.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read More.jpg;maxWidth=970;quality=90)

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)