High-Speed Spindles Powered by Coolant Pressure

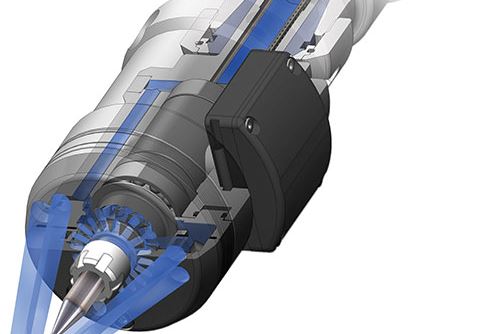

These spindles use a machine’s through-spindle coolant delivery system to achieve rotational speeds as high as 50,000 rpm.

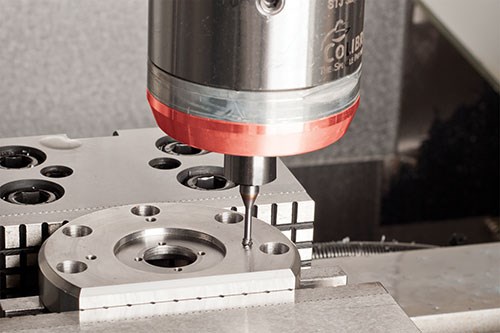

Auxiliary high-speed spindles offer a number of advantages. They enable a conventional machine tool to achieve the higher rpms that are typically required to effectively use small-diameter tools for semi-finishing and finishing operations. This increases a machine’s flexibility while saving energy and reducing wear and tear on its main spindle. It’s also possible to achieve faster cycle times and improve tool life by taking high-speed machining passes.

Common versions of high-speed spindles include electric, air turbine and mechanical “speeder” designs. That said, Colibri Spindles, an Israel-based spindle designer and manufacturer, has developed a new version that uses a machine’s through-spindle coolant delivery system to rotate the auxiliary spindle. Its coolant-pressure-driven high-speed spindles, distributed worldwide by the IMC Group, are well-suited for operations such as milling, drilling, engraving, chamfering, thread milling and grinding using small-diameter tools. IMC Group companies Iscar and Ingersoll market the spindles in North America under the names “Spinjet” and “Typhoon,” respectively.

According to Colibri, using coolant pressure to power the spindle overcomes a number of inflexibilities common to other types of high-speed spindles while offering lower operational costs. The Spinjet/Typhoon spindle models are available in 20-, 30- and 40-bar (290-, 435- and 580-psi) versions. The 20-bar spindles achieve 20,000 rpm, 30-bar spindle models can reach 30,000 or 40,000 rpm, and 40-bar models can reach 40,000 or 50,000 rpm. The company says tailoring machining parameters to these higher spindle speeds can enable shops to reduce machining time by as much as 70 percent.

The compact high-speed spindles can be stored in a machine’s ATC magazine when they are not being used and install in the main spindle like any standard tool. They are available for use with a number of spindle interfaces, including ER 32 shanks, cylindrical shanks, HSK A63, CAT 40, BT30 and 40, and Capto C5 and C6 (ISO 26623-1). The spindles attach to toolholder bodies via an ER 32 collet chuck, and cutting tools install into the spindles via an ER 11 collet chuck that accommodates a maximum tool shank diameter of 0.236 inch. Recommended tool diameters range from 0.0787 to 0.1378 inch for 20,000 rpm, 0.0394 to 0.0984 inch for 30,000 rpm, and 0.0078 to 0.0591 inch for 40,000 rpm.

To determine an approximate new feed rate for an existing operation being switched to high speed, Colibri suggests calculating the ratio of the auxiliary spindle speed to the original spindle speed, and multiplying that by the original feed rate. For example, if the existing operation used a spindle speed of 8,000 rpm and a feed rate of 6.3 ipm, the calculation for the new feed rate using a 30,000-rpm spindle would be:

(30,000/8,000) × 6.3 ipm = 23.6 ipm

Real-time spindle speed monitoring is possible using a compact display that connects wirelessly to the spindle via Bluetooth. The display can read speeds of as many as 127 spindles being used on a specific machine tool.

The spindles are available on new DMG MORI equipment, and their design has been integrated into SolidCAM’s iMachining software. SolidCAM built models for spindle use, which will make it easier to determine the proper cutting parameters, reduce the time needed to write part programs and shrink the learning curve.

Read Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.jpg;width=70;height=70;mode=crop)

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)