How Intelligent Clamping Technology Can Contribute to Process-Flow Optimization

Germany’s Metav 2018 trade fair presented various hands-on solutions in regard to Industry 4.0, automation, digitalization and data-driven manufacturing. One topic that stood out was intelligent clamping technology with integrated measurement capabilities to generate data to optimize machining processes.

Metav, the Düsseldorf, Germany-based show that takes place biennially in February, faces the burden of occurring only a few months after the world's biggest metalworking show, EMO Hannover, and a few months before world events such as AMB, the International Manufacturing Technology Show (IMTS) and the Japan International Machine Tool Fair (JIMTOF). As a result, exhibitors use the show to connect with customers from Northern Germany and don't necessarily present world-introduction solutions.

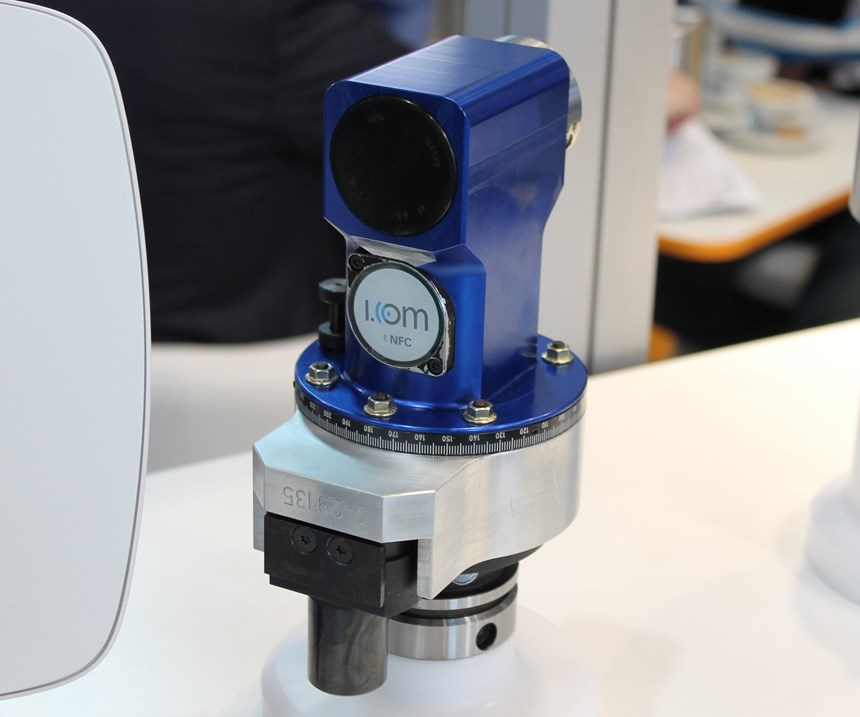

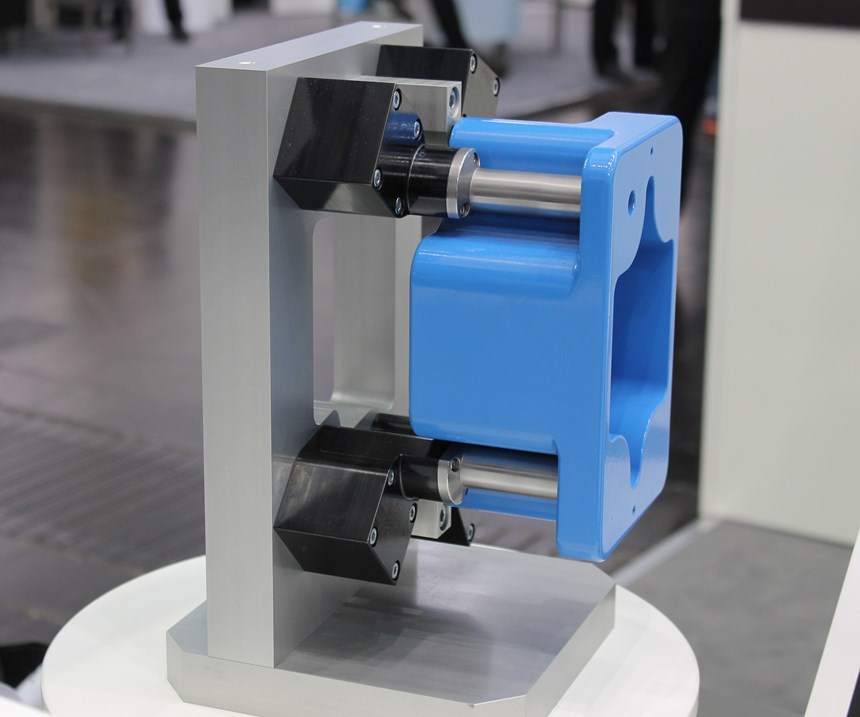

Therefore, for my coverage of the event, I focused on what is new in clamping technology, toolholding and workholding—areas in which customers are increasingly benefiting from solutions designed for the age of Industry 4.0. Exhibitors had a number of intelligent workholding and toolholding solutions for automation and networked manufacturing up their sleeves. Digital-workflow data collected from these “smart” devices can be used to manage process flows, and productivity can be increased by performing the appropriate analysis and data processing. Similarly, some new clamping technology generates data that can contribute to process-flow optimization. For example, tooling and maintenance times can be reduced in advance and the machine time can be used for production instead.

Click through the slideshow above to see a sampling of some of those technologies I spotted at the show.

Related Content

-

A Case for Combining Workholding with Optical Scanning

Automotive dies and die inserts are often complex, one-off parts with little room for error. Integrity Tool's investments in modular workholding tools and 3D optical scanning have allowed the company to create niche capabilities for its CNC machined parts.

-

An Additive Manufacturing Machine Shop

Finish machining additively manufactured implants requires different pacing and workflow than cutting parts from stock — different enough for an experienced manufacturer to warrant a dedicated machine shop.

-

Modern Bar Feeds Bring New Life to Automatic Swiss Lathes

Cam-actuated Swiss lathes are still the fastest way to process many parts. By adding modern bar feeders, this shop has dramatically improved their utilization with the ability to work unattended, even in a lights-out environment.

.png;maxWidth=300;quality=90)