JIMTOF 2016 Report: Exhibitors Show a Strong Embrace of IIoT

The recent Japan International Machine Tool Fair reflects the rapid move toward smart factories in which smart machines are fully networked.

Editor's Note: To see a slideshow that samples other exhibits at JIMTOF, click here.

The message from JIMTOF 2016, Japan’s premier machine tool show, was strikingly clear: Japanese providers of manufacturing technology have embraced the concepts of the Industrial Internet of Things (IIoT). Although there is no exact definition for what this phrase means, it undoubtedly refers to the strategy of linking machine tools and other shopfloor equipment to a web-enabled network that makes manufacturing increasingly data-driven. (The trend to data-driven manufacturing is more commonly referred to as Industry 4.0 among European developers, but this term was quite rarely used at JIMTOF.)

When machines are connected to a network, a stream of data reflecting their operational status and the condition of their components and subsystems can flow to processing centers on various levels for monitoring, analysis, decision-making and problem-solving. In fact, the Japanese Machine Tool Builders’ Association (JMTBA), the organization sponsoring JIMTOF, identified IIoT as the main component of its stated JIMTOF theme of “The Future Starts Here.”

The IIoT capabilities of various machine builders in Japan were prominently displayed in booth exhibits. In general, these exhibits highlighted how data can be transformed into actionable information to avoid downtime and improve productivity through more thorough and timely monitoring.

The show also indicated that, for machine tool builders, the premier interoperability/data exchangeability standard is MTConnect, which is apparently being widely adopted to promote shopfloor connectivity. MTConnect is described as a set of open, royalty-free standards intended to foster greater interoperability between machines, devices, control systems and software applications. Originally developed in the United States through the support of AMT—The Association For Manufacturing Technology, Japanese builders took an early interest in MTConnect. Most notably, Mazak Corp.’s North American manufacturing headquarters in Florence, Kentucky, made MTConnect a major part of its iSmart Factory concept. MTConnect is now reportedly utilized in several Mazak plants in Japan as part of the company’s thrust toward IIoT technology.

Significantly, a seminar on MTConnect was also presented at JIMTOF under the sponsorship of AMT. Attendance at this seminar indicated strong interest in the standard by both technology developers and end users.

Two Big Challenges

In addition to interoperability and data exchangeability, JIMTOF exhibitors are confronting two other major challenges in IIoT implementation: network security and effective data computing. For network security, two approaches, both involving network switching and routing, were apparent. One is to embed a configurable network switch inside a machine’s CNC to manage network exposure internally. The other approach is to “bolt on” an external device that incorporates the network switch and forms the secure interface to the network. Builders promoting IIoT-ready systems seem to be favoring the former approach, whereas builders striving for IIoT compatibility of existing products and legacy machines in the field are favoring the latter. These approaches are not in conflict, but rather represent the range of options available for IIoT implementation.

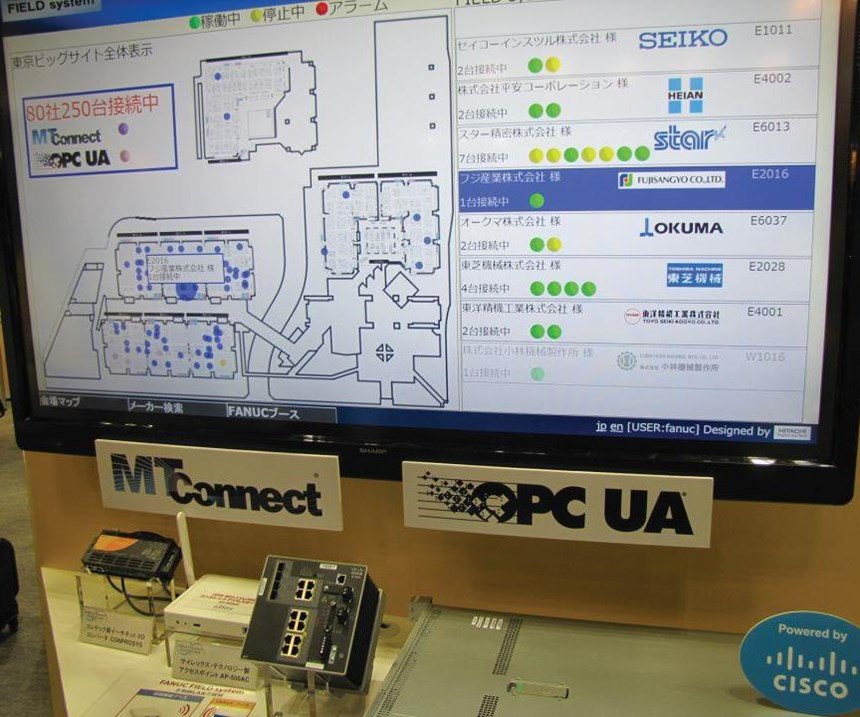

The challenge of effective data computing boils down to a very practical matter. Because the flow of data from connected machines can be voluminous, managing when, where and how to process this data is critical. Although cloud-based applications can bring to bear virtually unlimited computing power to the tasks of collecting, analyzing and storing vast amounts of data, deriving and delivering actionable intelligence to the shop floor in a timely fashion is a problem. It is eliciting an alternative concept—that of “edge” computing or computing in the “fog.” At JIMTOF, this development was most plainly proposed by FANUC, Japan’s largest CNC and factory automation supplier. It is embodied in the company’s FIELD (FANUC Intelligent Edge Link and Drive) system, an emerging automation platform being developed with partners such as Cisco, Rockwell Automation and Preferred Networks.

Here, the principle is to conduct data computing and analysis with resources shared within a corporate network, but away from a centralized capability such as a cluster of servers in one location. In this usage, “edge” has two connotations: computing stays within the boundaries of the network, but away from the center. Likewise, “fog” computing implies that resources such as CPUs and memory banks in the network can be shared when tasks are distributed among them. If fog is literally a cloud on the ground, then figuratively, fog computing is cloud-like yet stays grounded in the local plant network.

The FIELD system is currently proving its value in “deep learning” applications that enable vision-equipped robots to enhance bin-picking capability. Analysis of each robot’s successful and unsuccessful attempts to locate and grasp a randomly sorted part yields new and better rules to guide the robots, making all of them more effective (“smarter”) as a group.

Other Noteworthy Trends

Making machine tools ready for IIoT was certainly not the only significant trend detectable at JIMTOF. Hybrid machines that combine subtractive processes (conventional milling, grinding, turning and so on) with additive processes (laser cladding, wire arc welding, laser metal deposition) were notable. The Japanese government is providing substantial funding for research in hybrid technology, and this showing reflects that support.

Additionally, several builders have incorporated collision-avoidance features into the software in the CNC. Essentially, the simulation of the machining program stays ahead of its actual execution, creating an opportunity for the software to detect and avoid impending crashes or interference. Similar protection safeguards axis moves when the operator is jogging the machine into position.

Another frontier that machine tool builders are pushing into is machining accuracy in the sub-micron level. Applications range from miniaturized electronics to advanced designs of airspace components such as jet engine blades.

Finally, it should be noted that JIMTOF 2016 marked the opening of two new exhibit halls, thereby increasing exhibit space to nearly 100,000 square meters. The new halls, East 7 and 8, were dedicated largely to overseas exhibitors who have been closed out of this show in the past because of strong participation by domestic exhibitors. Adding a new show entrance by the new halls helped improve visitor traffic to the exhibit space, although some long-time exhibitors who were seemingly relegated to the overseas exhibit area this year were not entirely pleased.

Overall, JIMTOF is at once a manageable show size-wise, yet gratifyingly innovation-rich. And characteristically, the Japanese combine orderliness with flair, daring technology with graspable objectives, and bold moves with respect for tradition. JIMTOF exemplifies monozukuri, a Japanese word that means “the art of making things better than ever.” It can also be translated as “the proud spirit of dedicated craftsmanship.” Monozukuri gives JIMTOF a zest that distinguishes it from any other show.

Learn more about Okuma America.

Related Content

Wireless Couplers Work Wonders for Workholding

Possibilities range from individual control of chuck jaws and tombstone fixtures to more reliable robots.

Read MoreCan Connecting ERP to Machine Tool Monitoring Address the Workforce Challenge?

It can if RFID tags are added. Here is how this startup sees a local Internet of Things aiding CNC machine shops.

Read MoreHow this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

Read MoreBeyond the Machines: How Quality Control Software Is Automating Measurement & Inspection

A high-precision shop producing medical and aerospace parts was about to lose its quality management system. When it found a replacement, it also found a partner that helped the shop bring a new level of automation to its inspection process.

Read MoreRead Next

JIMTOF: A Strong Embrace of IIoT

The recent Japan International Machine Tool Fair reflects the rapid move toward smart factories in which smart machines are fully networked. Japanese providers of manufacturing technology have clearly embraced the concepts of the Industrial Internet of Things.

Read More3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)

.png;maxWidth=300;quality=90)