Job Shop-Developed Dovetail Fixture Takes Wing

Two aerospace job shops in California collaborated to produce a workholding fixture that allows any shop to set up a fully fixtured pallet dedicated to a five-axis job and then store the fixtured pallets for immediate use whenever the job repeats.

Like many shop owners, Brian O’Rell, president of Vanderhorst Brothers Inc. (VBI) in Simi Valley, California, knew that his strategy for workholding fixtures would "make or break" the productivity of his shop’s newest machining center. This machine, a five-axis VMC, was designed with multiple pallets. Because VBI specializes in repeat orders for complex aerospace components, Mr. O’Rell needed a system that would allow him to set up a fully fixtured pallet dedicated to each job and then store the fixture pallets for immediate use whenever the job repeats.

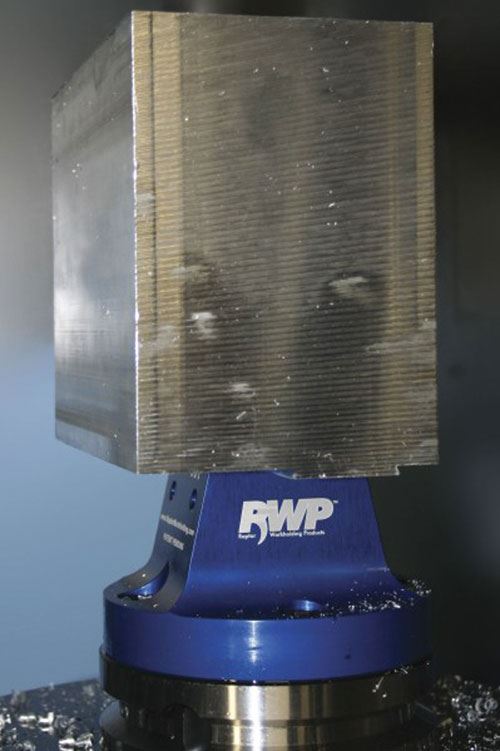

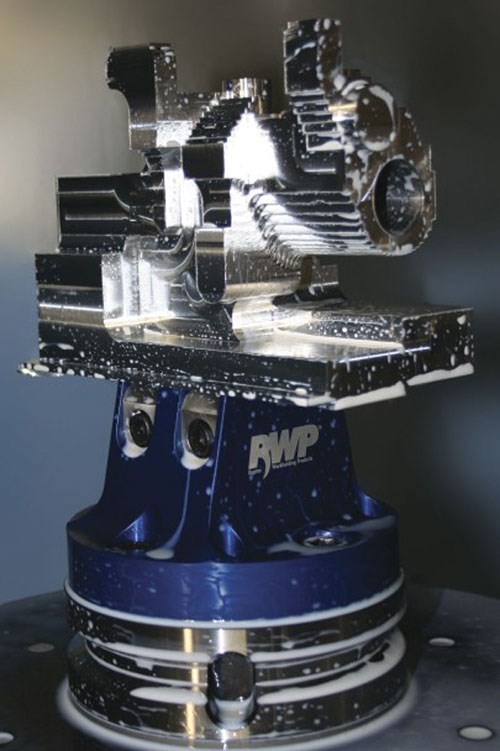

The fixtures had to be affordable because he needed a lot of them. They had to provide rigid clamping without distorting the workpiece. They had to allow quick loading and unloading of the parts to keep setup time within the targets demanded by lean manufacturing. The fixtures had to get the workpieces away from the surface of the pallet so the spindle could reach all exposed faces of the workpiece for five-axis machining without interference. Finally, they had to minimize the clamping stock required in workpiece blanks to reduce material waste.

Mr. O’Rell was not entirely satisfied with the workholding fixtures available commercially, so he decided to make is own.His original design was based on traditional mating dovetail methods he had been using for sometime. The initial batch of fixtures worked well enough that he recommended them to another shop owner, David Fisher of S & H Machine, Inc. (S&H) in Burbank, California. Mr. Fisher had a new five-axis machine identical to Mr. O’Rell’s and was struggling with the same workholding challenges.

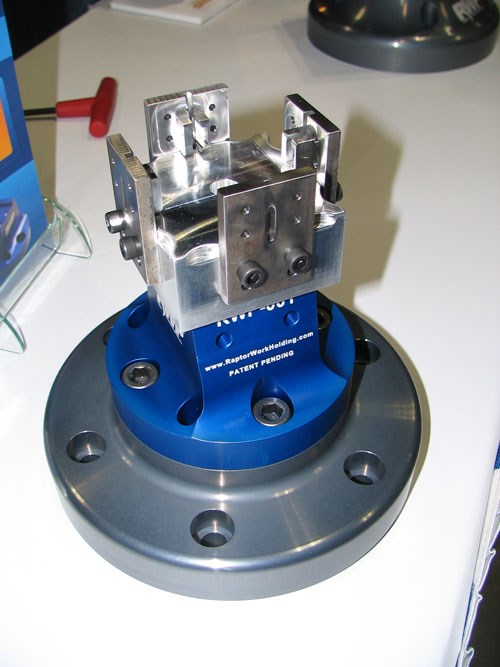

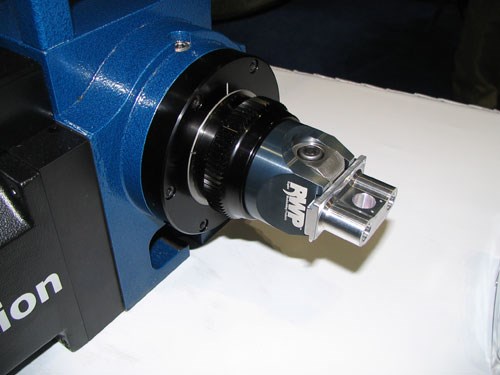

Mr. Fisher immediately recognized that the fixtures would worked well in his shop, too, but S&H Vice President and Production Manager Dao Ha had his own ideas to improve the design. So the two shops combined their ideas, refined the clamping concept and decided to bring it to market. Thus, Raptor Workholding Products (RWP) was born, a joint venture of the two companies. The new company’s first offering is this jointly developed dovetail fixture, for which patent protection is underway. It is available in two sizes, a 1.5-inch model and a 0.75-inch model.

Mr. O’Rell says several features set the fixture apart from other designs. For example, the fixture has a solid dovetail interface on one side. This serves as the solid stop against which a workpiece is clamped by two spring-loaded, stainless steel dovetail clamps on the opposite side of the fixture. Another feature, a locating screw adjacent to the solid stop, provides workpiece positioning and prevents a part from being loaded backwards.

For clamping purposes, a shallow dovetail "strip" must be machined on the clamping side of the blank workpiece. The width of this dovetail strip matches the dovetail "slot" on the fixture. The strip is only 1/8 inch high, so it requires little extra stock. The dovetail can be machined with a standard 60-degree dovetail cutter or one purchased from RWP. A slot that fits against the locating screw must also be milled. Because these machined features are standardized, programmers can duplicate the necessary configurations into all CNC part prep programs.

The operator loading material on the fixtures simply places one side of the dovetail strip against the solid side and then tightens the clamps. This presses the material blank firlmy against the solid side. The capscrews in the clamps are

then tightened to secure the workpiece. Mr. O’Rell claims that the hardened clamps provide strong, even clamping pressure with no side-to-side movement, even during heavy cuts on large workpieces.

The fixture base is a tapered pedestal on a circular foot that has bolt holes for mounting in the T-slots or threaded holes in the pallet. The base can also be mounted on a tombstone in a HMC or mounted on a lathe. The fixtures are 3 inches high and 5 inches in diameter. Risers are available for applications requiring additional clearance height. The fixtures can be customized or fitted to any machine or index table with adapter plates for existing fixture mounts.

"We’ve decided that every five-axis part we run will be held using a Raptor dovetail fixture," Mr. O’Rell says. "Accordingly, almost all the pallets in our five-axis mill are loaded with RWP-001s and RWP-002s, although we have a new 5C version—the RWP-003—for smaller workpieces. We’ve incorporated the solid models into our CAD/CAM templates so that our programmers see exactly where the fixture sits in the machine’s envelopeWith this arrangement, we no longer need to spend time designing workholding solutionsfor our first milling operations (and on the five-axis machine, the first milling operation usually completes all of the major part features). We’re still able to produce a wide variety of parts on a shared machine, but we’ve eliminated the changeover time," Mr. O’Rell concludes.

Related Content

Top Shop Builds Upon Employee Ownership for Future Success

In its quest to become the Fox Valley’s best-in-class employer, A to Z Machine has adopted an ESOP, expanded benefits and invested in apprenticeships.

Read MoreIMTS Takeaways From the Modern Machine Shop Editorial Team

The first in-person IMTS in four years left the MMS editorial staff with a lot to digest. Here are a few of our takeaways from the show floor.

Read MoreAll-Around Mill Improves Productivity and Cost for Valve Job

Adopting a mill with a double-negative rake and pockets compatible with multiple insert geometries enabled Progressive Metal Service to increase feed and lower scrap rates for a valve.

Read MoreHow to Grow the Business with Real-Time Job Status Data

ERP systems that focus on making data more accessible can improve communication within a shop, reducing wasteful errors and improving capacity.

Read MoreRead Next

3 Mistakes That Cause CNC Programs to Fail

Despite enhancements to manufacturing technology, there are still issues today that can cause programs to fail. These failures can cause lost time, scrapped parts, damaged machines and even injured operators.

Read MoreThe Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

Read More

.png;maxWidth=300;quality=90)