Laser Encoder Feedback for 40-Meter Wing Parts

Large machine travels, long machining cycles and changing aircraft manufacturing precision demands necessitated a non-contact approach to machine-tool position feedback.

Some of the largest machined parts being produced for aircraft today require the machine tool builder to rethink basic, and generally unappreciated, components of the machine. That was the case with waterjet machine tool maker Flow International Corporation. The company’s Composites Machining Center combines waterjet cutting and conventional milling and drilling in one machine to produce 40-meter-long composite wing skins for aircraft. On a machine cutting parts this long, Flow found that tape scales were ineffective for measuring the axis travel, particularly that of the long X axis. The potential for thermal variation across the long time span required for these large parts’ machining cycle was too large for the skins’ required accuracy. Therefore, in place of solid scales, Flow applied laser encoders from Renishaw, which use non-contact laser interferometry for precise measurement over long distances.

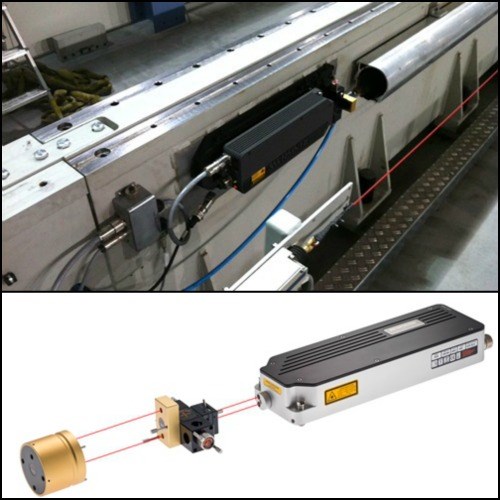

The laser encoder system uses interferometry to achieve precise non-contact machine position feedback across long axis travels.

The wing skins have precision demands unlike large aircraft parts of the past, says Mark Saberton, Flow’s director of aerospace. Aircraft makers want to eliminate assembly shimming. That is, “They want parts to meet tolerances when they arrive on the assembly floor, rather than using fixtures and shims to bring parts into assembly tolerance,” he says. Eliminating mass is a related objective. “Less variance on a plane’s parts ensures better control of the aircraft’s final weight.” Thus, the ability of the machine tool to position precisely translates directly to a better-performing aircraft.

The length of the parts alone is not what makes tight positioning a challenge. The length of the machining cycle is also a factor. The machining cycle for a 40-meter-long composite skin could last 130 hours. Todd Fuchs, senior electrical project engineer at Flow, says a physical scale 40 or 50 meters long that is attached to the machine makes for challenging thermal compensation across that much time, even in an air-conditioned plant. “Between changes in the scale itself and the substrate of the machine, the variables become too complex,” he says. The laser encoder system, which achieves accuracies measured in parts per million in part by using sensors to compensate for the thermal expansion of the machine structure along with changes in the refraction of the air, offers an easier way to obtain consistently accurate feedback the machine’s long axes.

Related Content

-

The Cut Scene: The Finer Details of Large-Format Machining

Small details and features can have an outsized impact on large parts, such as Barbco’s collapsible utility drill head.

-

ESOP Solidifies Culture of Continuous Improvement

Astro Machine Works’ ESOP rewards all employees when the shop does well, inspiring many toward continuous improvement as Astro expands its capabilities.

-

Heavy Engineering: The Complex Logistics of Moving Large Machine Tools

One of our fascinations with large-format machine tools has little to do with their capabilities, but everything to do with the logistics involved with getting them up and running. Here’s how one of the world’s oldest builders of giant machine tools tackles the challenge.

.jpg;width=70;height=70;mode=crop)